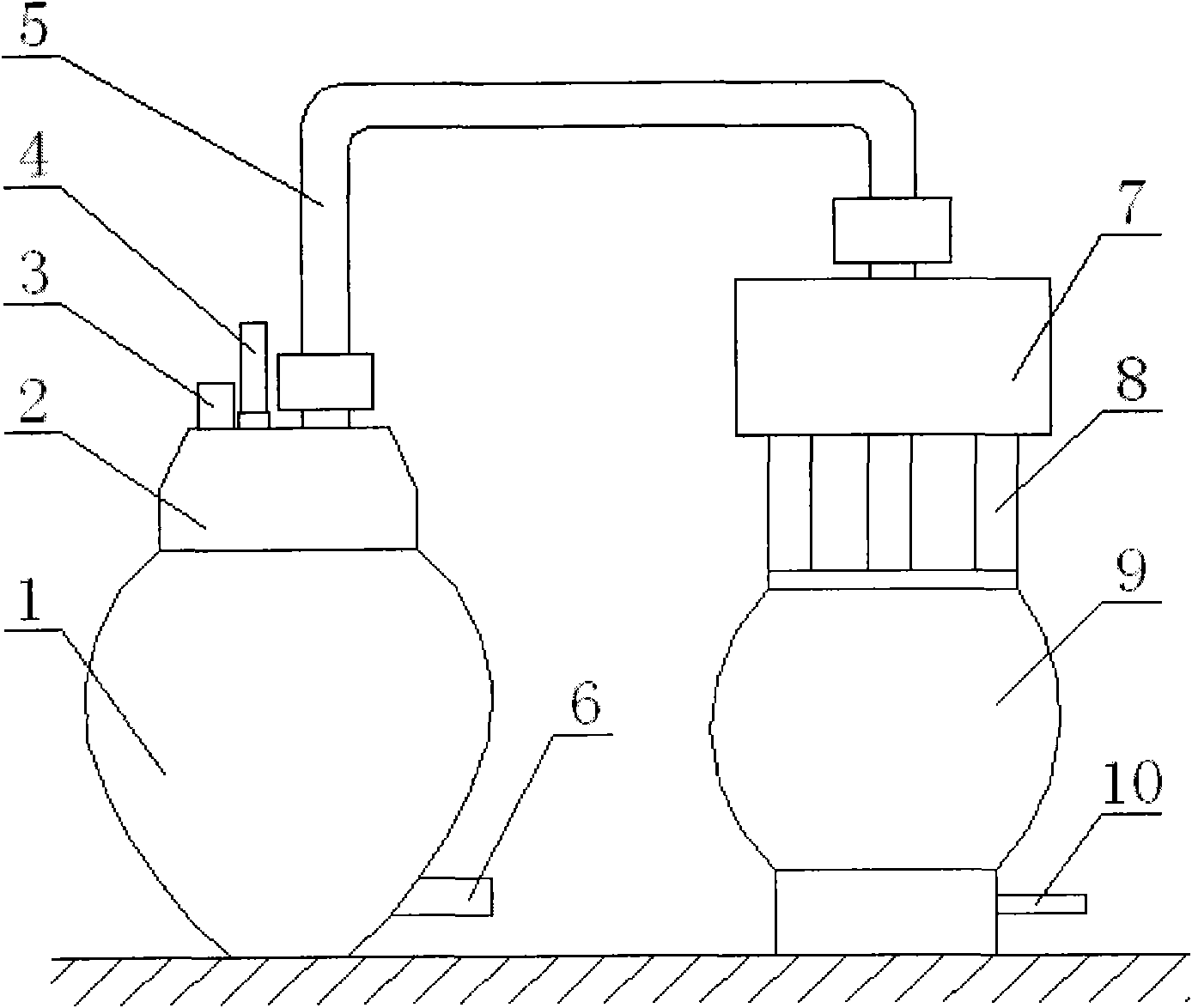

Method and equipment for distilling pottery jar wine

A technology of wine steaming equipment and pottery vats, which is applied in the field of wine making, can solve the problems that pottery vats cannot be popularized and applied, wine is highly irritating to the mouth, and metal equipment is easy to rust, etc., and achieves simple structure, long aftertaste and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

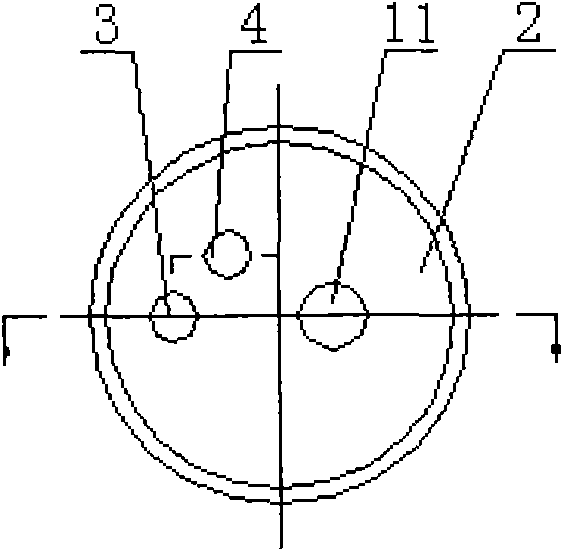

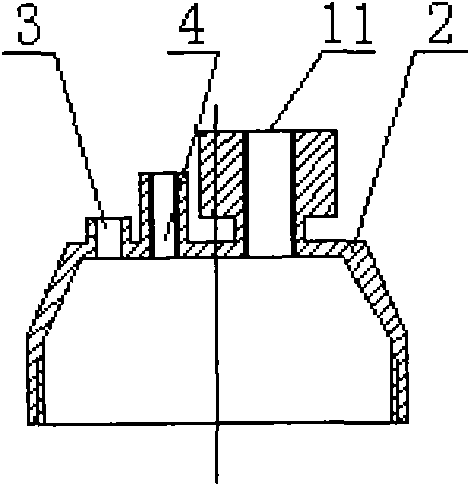

Method used

Image

Examples

Embodiment 1

[0036] Using rice as a raw material, the method and equipment for steaming wine in pottery vats of the present invention are illustrated.

[0037] Rice raw material 150kg, distiller's yeast 30~75g, adopt rhizopus: alcoholic yeast: ester-producing yeast (hansenula (hansenula) or candida (Candida)) is 1: 1: 0.5, and its technological process is as follows:

[0038] 1. Cooking. First soak the raw rice for 8 hours, take it out and put it on the steamer to steam into rice;

[0039] 2. Cool down. Take the steamed rice to a clean place and let it cool;

[0040] 3. Mixing materials. When the temperature of the above cooled rice drops to about 28°C, add the koji and stir evenly;

[0041] 4. Fermentation. Stack the raw materials of the mixed koji so that the middle is low and the surroundings are high, like a "V" shape, cover with a film, and ferment for about 20 hours until the liquid seeps out and has a sweet taste, then put it into a fermentation container, cover it Continue to...

Embodiment 2

[0044] Using rice and sorghum as raw materials, the method and equipment for making liquor in pottery vats of the present invention are described.

[0045] Rice raw material 150kg, sorghum 100kg, distiller's yeast 50~125g, adopt rhizopus: alcoholic yeast is 1: 1, and its technological process is as follows:

[0046] 1. Cooking. First soak the raw rice and sorghum for 12 hours, take it out and put it on the steamer to steam into sorghum rice;

[0047] 2. Cool off. Take the above steamed sorghum rice to a clean place and let it cool;

[0048] 3. Mixing materials. When the temperature of the above cooled rice drops to about 26°C, add the koji and stir evenly;

[0049] 4. Fermentation. Stack the raw materials of the mixed koji so that the middle is low and the surroundings are high, like a "V" shape, cover with a film, and ferment for about 20 hours until the liquid seeps out and has a sweet taste, then put it into a fermentation container, cover it The film will continue to...

Embodiment 3

[0052] Using rice as a raw material, the method and equipment for steaming wine in clay pots of the present invention are described to illustrate the process of making liquor.

[0053] Rice raw material 200kg, folk wine cake 1-3kg, the process is as follows:

[0054] 1. Cooking. First soak the raw rice for 10 hours, take it out and put it on the steamer to steam into rice;

[0055] 2. Cool off. Take the steamed rice to a clean place and let it cool;

[0056] 3. Mixing materials. When the temperature of the above cooled rice drops to about 28°C, add the wine cake and stir evenly;

[0057] 4. Fermentation. Stack the raw materials of the mixed wine cake into a low center and high surroundings, like a "V" shape, cover with a film, and ferment for about 20 hours until the liquid seeps out and has a sweet taste, then put it into a fermentation container, Cover with a film and continue to ferment for about 8 days, then put it into a large ceramic vat for aging and fermentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com