Method for manufacturing industrial phosphoric acid, industrial ammonium phosphate and food-grade phosphoric acid from medium and low-grade phosphorite by one-step extraction of hydrochloric acid method

An industrial phosphoric acid, industrial ammonium phosphate technology, applied in chemical instruments and methods, phosphoric acid, phosphate, etc., can solve the problems of troublesome operation and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

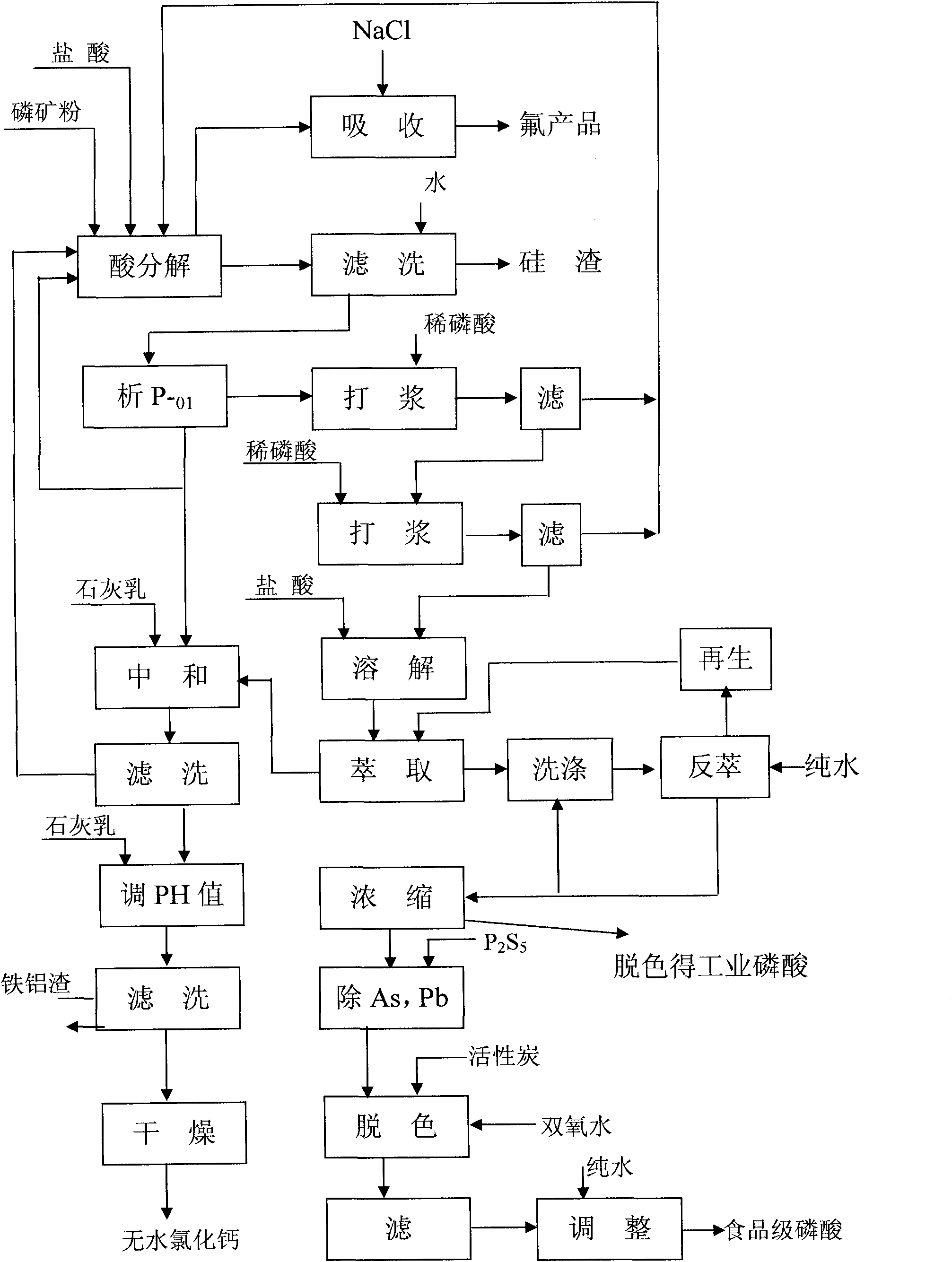

Method used

Image

Examples

Embodiment Construction

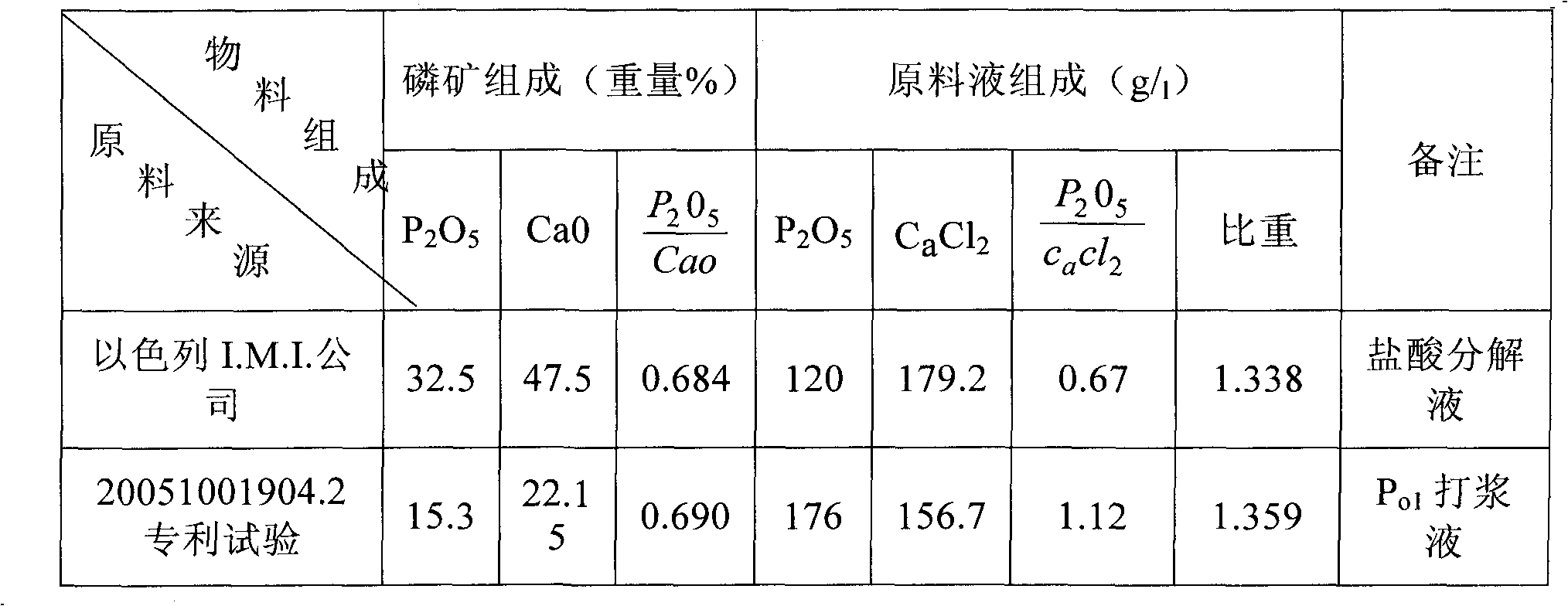

[0038] Table-3, used phosphate rock (weight %)

[0039]

[0040] Generally, in the cyclic process test, the process parameters are relatively stable when the cycle reaches more than 4 times. Here, the 7th cycle is taken as an example to describe the implementation of the cyclic dissolution of this process.

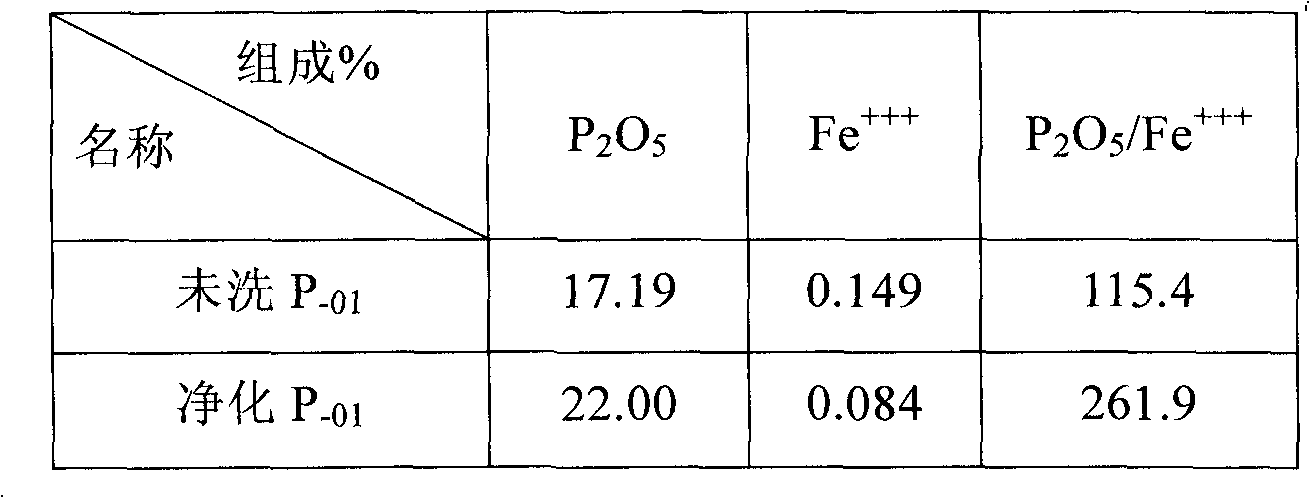

[0041] P -01 Put 660ml of mother liquor, 500ml and 1500ml of tap water, and HCl=30% hydrochloric acid into a 5000ml large beaker, heat it in an electric furnace to above 60°C, start to slowly put in 1,000g of No. 3 mineral powder (over 0.35mm), and react at nearly 100°C with stirring , the generated foam is separated by a two-stage cyclone separator, and in the liquid phase reflux decomposition reaction, the gas phase is absorbed by a concentrated salt solution to generate some Na 2 SiF 6 After throwing ore, stir for another 10 minutes, and suction filter while it is hot to obtain 2823g of decomposed solution, wet silicon slag, which is 144.3g after drying, and 1155.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com