Double-type air-distribution plate and single pipe discharging sending tank

A technology of air distribution plate and sending tank, which is applied in the direction of conveyors, conveying bulk materials, and gasification of granular/powdered fuels. It can solve problems such as low space utilization, bridging, and unstable control, and improve the internal space. Utilization rate, prevention of pulverized coal bridging, effect of large solid-gas ratio range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

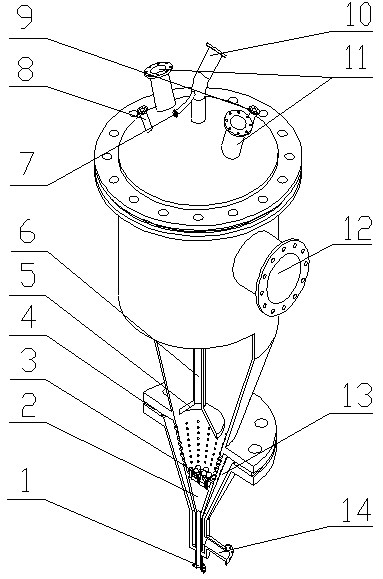

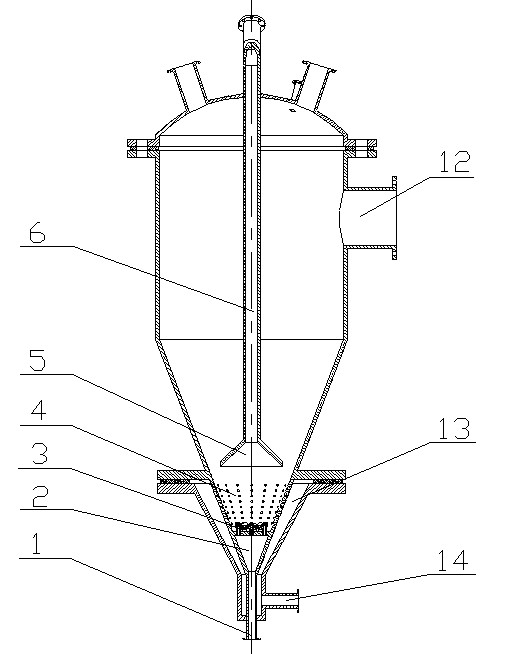

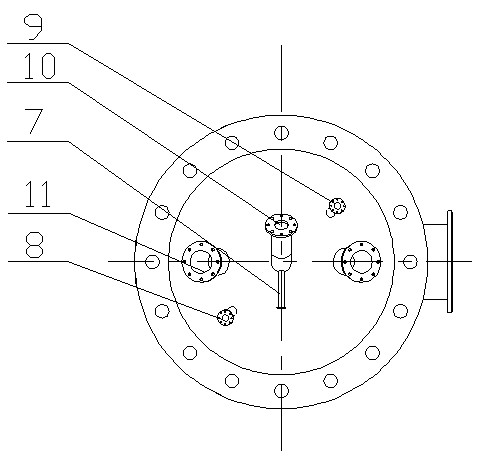

[0025] Such as Figure 1-3 As shown, the double-type air distribution plate and the single-pipe upper discharge sending tank include a tank body with a cylindrical upper half and a conical lower half. The lower half of the cone is provided with a main stream The air chamber 2 and the auxiliary fluidization air chamber 13, the auxiliary fluidization air chamber 13 is socketed outside the mainstream air chamber 2, and the main flow air distribution board 3 and the auxiliary fluidization air cloth are arranged in the main flow chamber 2 upwards in sequence Wind board 4.

[0026] The upper end of the auxiliary fluidized air distribution plate 4 is provided with a pulverized coal pipeline 6 passing through the top of the sending tank, and the lower end of the pulverized coal pipeline 6 is provided with an umbrella cover 5 that opens toward the auxiliary fluidized air distribution plate 4 .

[0027] The top of the sending tank is provided with a pressurized air inlet 88 .

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com