Compositions comprising thermoplastic starch

一种热塑性淀粉、组合物的技术,应用在包含TPS和聚烯烃的组合物领域,达到易于熔融再生、淀粉含量高、好机械性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

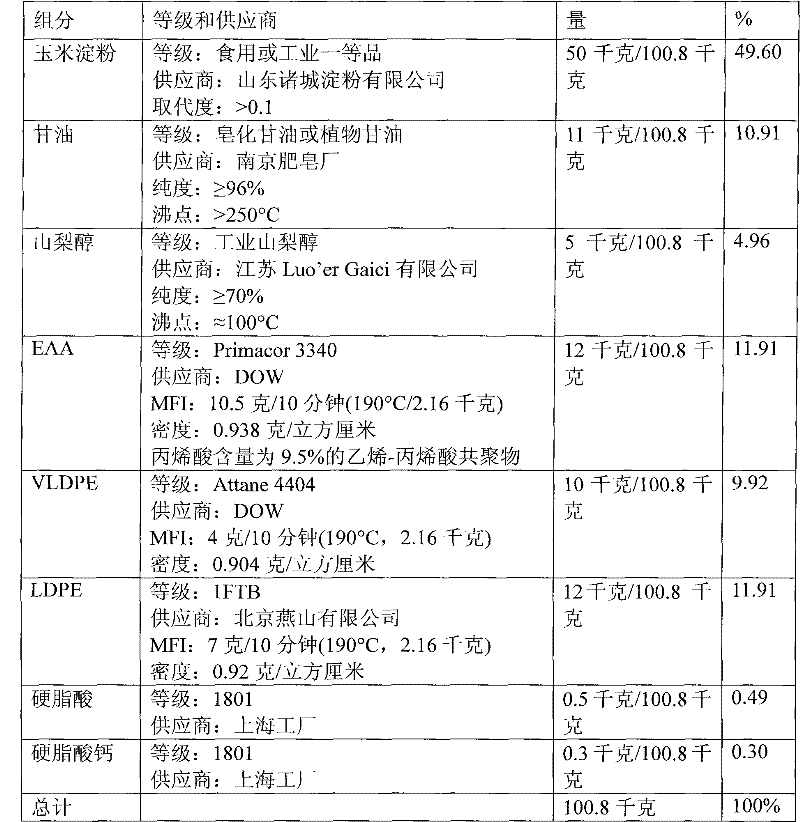

[0069]First, the components listed in the following Table 1 (composition A) were added in the order of starch, EAA, VLDPE, LDPE, calcium stearate, stearic acid, glycerin and sorbitol into a high-speed mixer for blending. The resulting physical blend was then melt processed in a vented twin-screw extruder having a melting profile of 140 / 170 / 175 / 175 / 165 / 155°C with a torque of < 80%, the screw speed is 320-350 rpm, the vacuum is -0.05 bar, and the output is 200 kg / h. Films were then blown from a composition of 50% by weight of Blend A and 50% by weight of LLDPE. The resulting film had a gauge of 15 microns, a tensile strength at break of 14 MPa and an elongation of greater than 200% (measured using a universal tensile testing machine).

[0070] Table 1: Composition A

[0071]

Embodiment 2

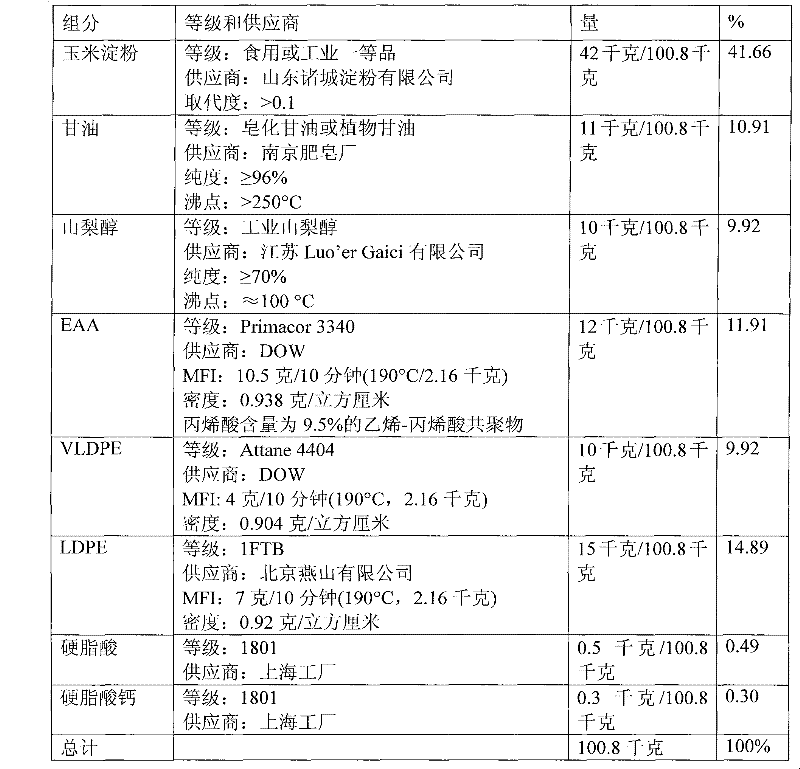

[0073] First, the components listed in the following Table 2 (composition B) were added into the high-speed mixer in the order of starch, LDPE, VLDPE, EAA, calcium stearate, stearic acid, glycerin and sorbitol for blending. The resulting physical blend was then melt processed in a vented twin-screw extruder having a melting profile of 140 / 170 / 175 / 175 / 165 / 155°C with a torque < 80%, the screw speed is 320-350 rpm, the vacuum is -0.05 bar, and the output is 200 kg / h. Blend B was then used to blow the film. The resulting film has a tensile strength at break greater than 10 MPa and an elongation greater than 250% (measured using a universal tensile testing machine). The film exhibits excellent antiblocking and antistatic properties.

[0074] Table 2: Composition B

[0075]

Embodiment 3

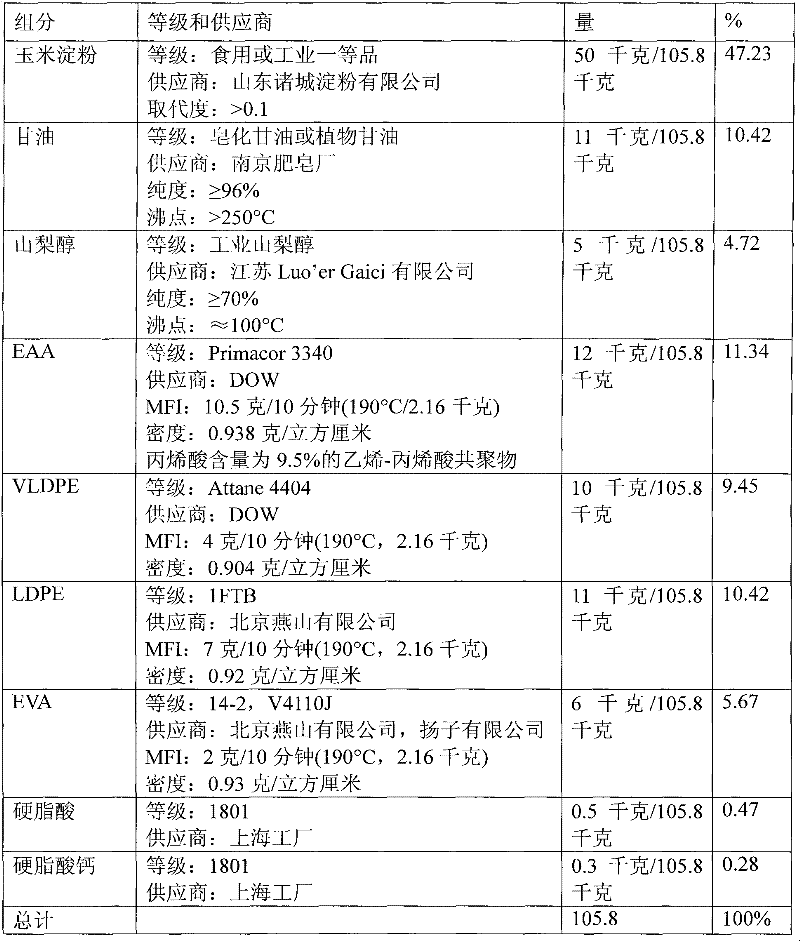

[0077] First, the components listed in the following Table 3 (Composition C) were added in the order of starch, EAA, VLDPE, EVALDPE, calcium stearate, stearic acid, glycerin and sorbitol into a high-speed mixer for blending. The resulting physical blend was then melt processed in a vented twin-screw extruder having a melting profile of 140 / 165 / 170 / 170 / 170 / 155°C with a torque of < 80%, the screw speed is 320-350 rpm, the vacuum is -0.05 bar, and the output is 200 kg / h. Blend C was foamed by melt processing Blend C with a conventional blowing agent masterbatch. The resulting foam is suitable as a flexible foam packaging material and has excellent softness and soft touch.

[0078] Table 3: Composition C

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com