Low-lactose and lactose-free dairy products and methods for their manufacture

A dairy product and low-lactose technology, applied in dairy products, milk preparations, applications, etc., to achieve the effect of loss avoidance and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

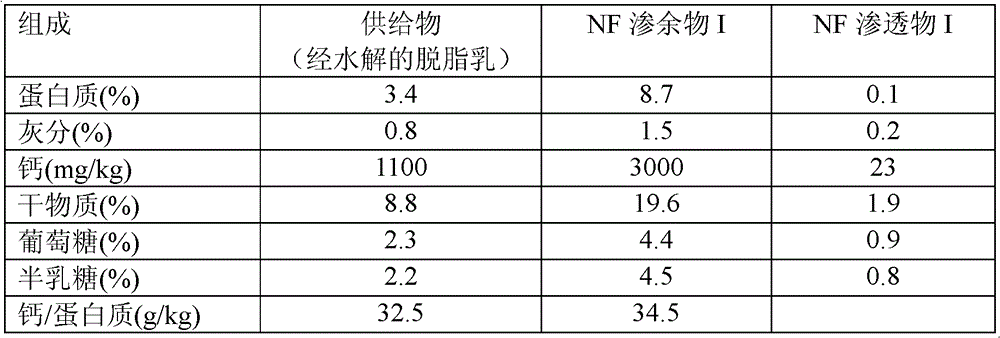

[0063] Example 1: Single stage nanofiltration of hydrolyzed skim milk with Desal 5DL membrane (K=3)

[0064] With 0.08% dose of Godo YNL2 lactase (Godo Shusei Company, Japan), skimmed milk (20L) was hydrolyzed (9°C, 18 hours), and at a temperature of 10°C to 18°C and a pressure of 12 to 21 bar to Desal 5DL membrane (GE Osmonics, USA) was used for nanofiltration. The permeate flow is 5.71 / m 2 h~9.61 / m 2 h. Continue to perform nanofiltration until the concentration factor is 3, the retentate volume is 6.7L, and the permeate volume is 13.3L.

[0065] Samples were taken from the feed consisting of hydrolyzed skim milk, the obtained NF retentate and NF permeate, on the basis of which samples protein, dry matter, glucose, galactose, ash and calcium were determined (Table 1).

[0066] Table 1: Nanofiltration Retentate and Permeate Composition

[0067]

[0068] Based on the above results it can be seen that, in fact, calcium was not lost to the permeate but remained in the s...

Embodiment 2

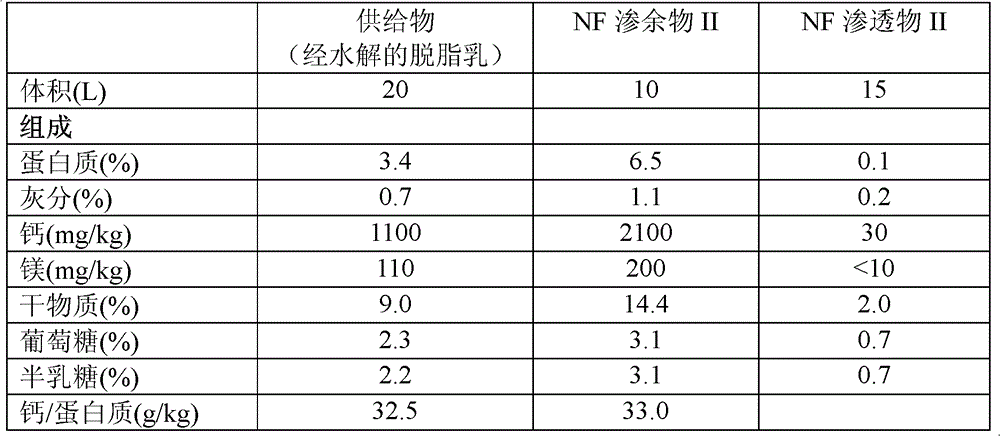

[0069] Example 2: Three-stage nanofiltration of hydrolyzed skim milk combined with RO filtration (membrane Desal DK + diafiltration + membrane Filmtec NF)

[0070] 0.06% Godo YNL2 lactase (Godo Shusei Company, Japan) was added to skim milk (20 L), and hydrolyzed at 10° C. for 18 hours. At this time, the residual lactose content of the skim milk was 0.03%. The hydrolyzed skim milk thus obtained was subjected to nanofiltration at 10°C to 15°C. The filter membrane is Desal 5DK (GE Osmonics, USA), the pressure is 13 bar to 19 bar, and the permeate flow is 8.4 l / m 2 h~10.5l / m 2 h. The hydrolyzed skim milk was first filtered with a concentration factor of 2, which meant that a total of 10 L of permeate was removed from the unit. Diafiltration was then performed by adding diafiltration water (5 L) to NF Retentate I (10 L) at the same rate as NF Permeate II was produced. The permeate from the first nanofiltration stage and the permeate obtained by diafiltration are recovered and ...

Embodiment 3

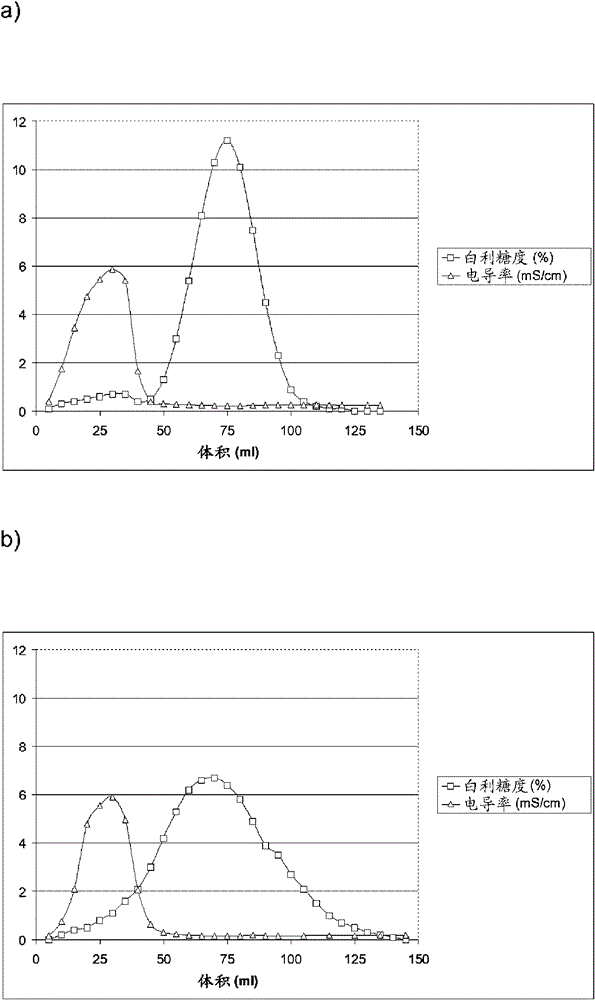

[0080] Example 3: Two-stage nanofiltration of hydrolyzed skim milk (membranes Desal 5DL (K=3) and Filmtec NF (K=6))

[0081] The staged nanofiltration of lactose-hydrolyzed skim milk was tested as follows: the first stage was carried out under warm conditions, and the NF permeate I obtained in the first stage was subjected to nanofiltration in a second stage under cool conditions to recover minerals .

[0082] Skim milk (40 L) was hydrolyzed (9°C, 18 hours) with Godo YNL2 lactase (Godo Shusei Company, Japan) at a dose of 0.08%, as described above. The hydrolyzed skim milk was subjected to nanofiltration at a temperature of 47°C to 51°C. The filter membrane was Desal 5DL (GE Osmonics, USA). Increase the pressure to keep the liquid flow constant. During the experiment, the permeate flow was 8.1 l / m 2 h~9.6l / m 2 h, the pressure is 4 bar to 6.4 bar. Filtration was continued until the concentration factor was 3.

[0083] The feed, retentate and permeate were sampled on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com