Light guide plate

A light guide plate and light incident surface technology, which is applied in the field of light guide plates, can solve the problems of uneven light output from the light guide plate, achieve uniform light output, and improve the effect of uneven brightness and darkness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

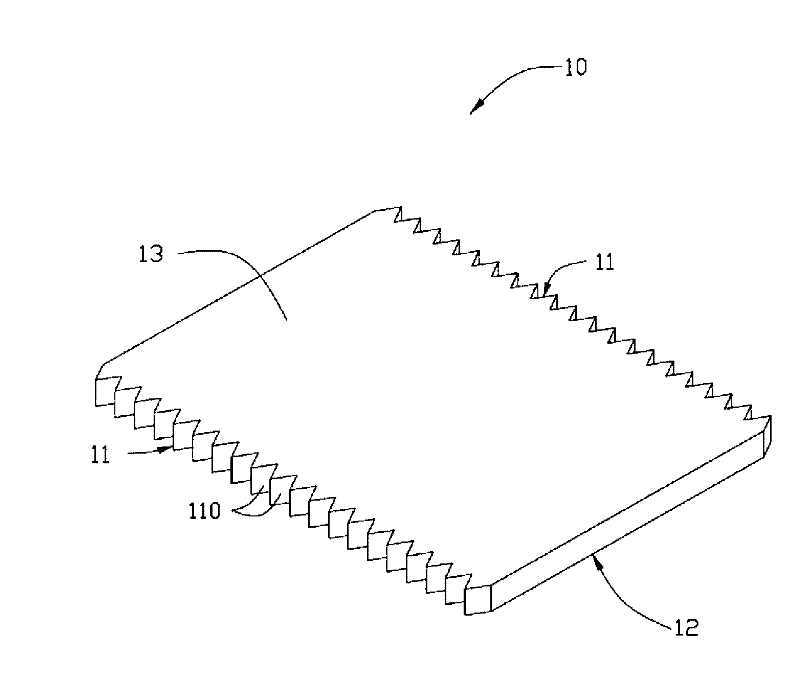

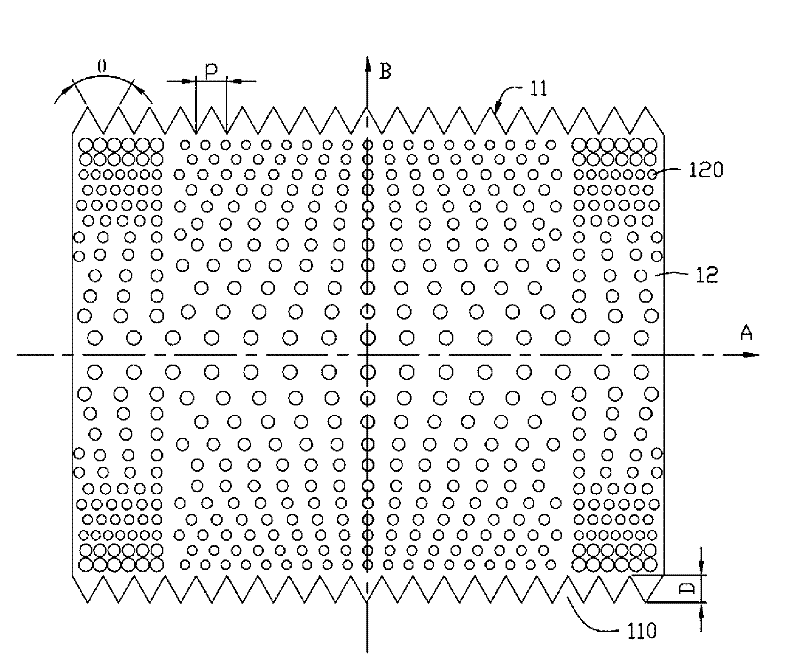

[0022] see figure 1 , which is a schematic perspective view of the first embodiment of the light guide plate of the present invention. The light guide plate 10 includes two opposite light incident surfaces 11 , a bottom surface 12 connected to the two light incident surfaces 11 , and a light exit surface 13 connected to the two light incident surfaces 11 and opposite to the bottom surface. The two light-incident surfaces 11 include a plurality of groove-shaped microstructures 110 , and the extending direction of the groove-shaped microstructures 110 is perpendicular to the bottom surface 12 and the light-emitting surface 13 . The groove-shaped microstructure is continuously distributed V-shaped grooves.

[0023] Please also refer to figure 2 , which is a schematic plan view of the bottom surface 12 of the light guide plate 10 . Wherein, the apex angle θ=60±5° and the depth D=40±15 μm of each groove-shaped microstructure 110 . The distance between two adjacent groove-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Minimum diameter | aaaaa | aaaaa |

| The maximum diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com