Electromagnet and friction composite disc type brake and brake method

A technology of electromagnetic braking and composite disc, applied in the direction of brake type, axial brake, brake components, etc., can solve the problems affecting the thermal decay of the brake, the temperature rise of the brake disc, the temperature rise of the brake, etc., to achieve the braking force. The size is easy to control, the action time is reduced, and the effect of reducing the intensity of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

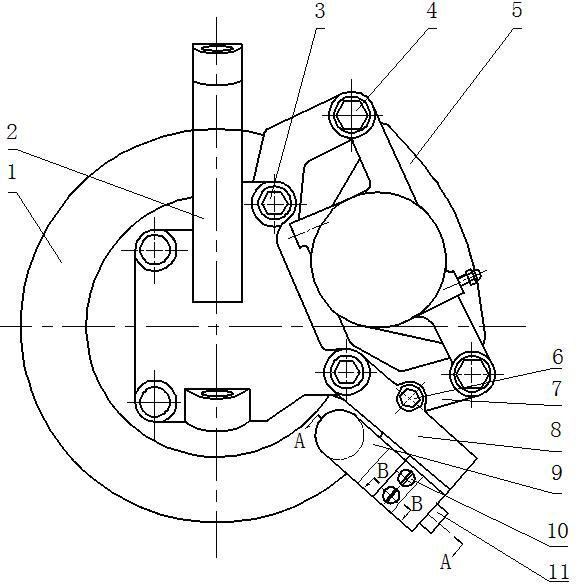

[0016] see figure 1 , 6 , 7, the present invention adds another brake caliper body 5 at one end of the brake caliper body of the traditional disc brake, the brake caliper body 5 is connected with the brake caliper bracket 7 through the brake caliper guide pin 4, and the brake caliper bracket 7 Located beside the brake disc 1, a steering knuckle 2 is arranged beside the brake disc 1, and a through hole is opened on the brake caliper support 7, and the brake caliper support 7 is connected to the steering knuckle 2 through bolts 3. The specific shape and size of the electromagnetic brake fixing device 8 are determined according to the size of the designed magnetic brake. One section of the electromagnetic brake fixing device 8 is also fixedly connected to the steering knuckle 2 through a bolt 3, and the other section is fixedly connected to the steering knuckle 2 through another bolt 6. Moving clamp bracket 7.

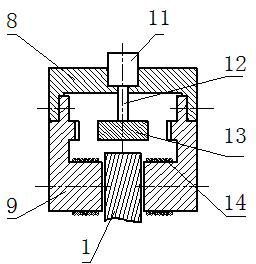

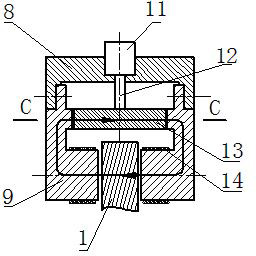

[0017] see Figure 1-5 , The electromagnetic brake fixing device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com