Plug-in mounting stand column hydraulic control one-way valve

A hydraulically controlled one-way valve, plug-in technology, applied in the direction of pillars/supports, mining equipment, earthwork drilling and mining, etc., can solve the problem of low service life and adaptability, difficult maintenance, high hydraulic impact of column hydraulically controlled one-way valves, etc. problems, to achieve the effect of easy installation and maintenance, long service life and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

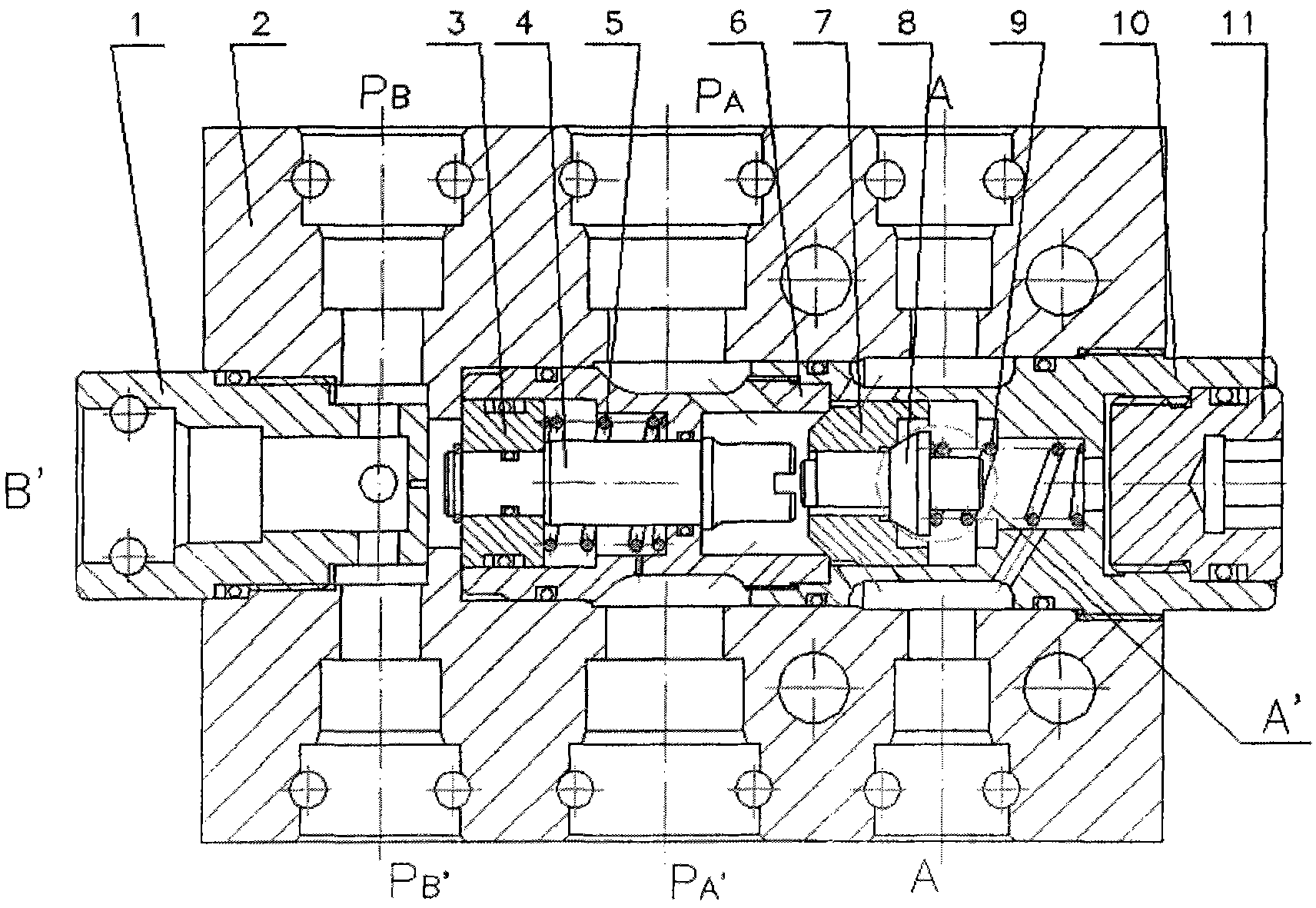

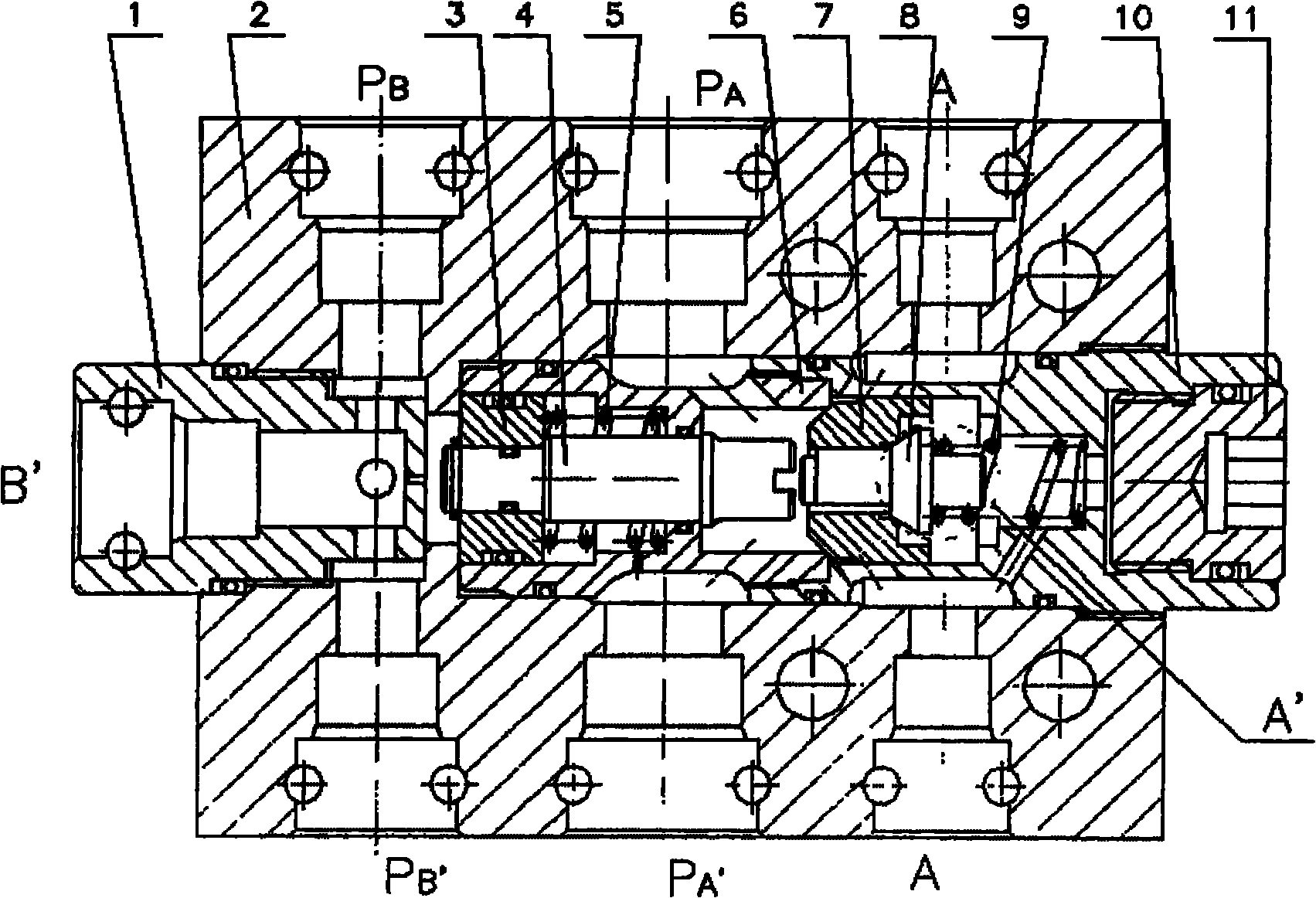

[0010] Such as figure 1 shown. The structure of the present invention is suitable for the column control of the large support in the middle and thick coal seams, including a joint 1, a compact flat sealing valve body 2 and a plug-in hydraulic valve core assembly. There is a piston 3 in the plug-in hydraulic spool assembly, and the piston is fixed on the ejector rod 4 by the shaft retainer ring to form an assembly. The ejector rod assembly is integrated with the liquid inlet valve sleeve 6 through a large spring 5 to form a ejector rod recovery chamber. When the control pressure liquid is closed and stopped, the ejector rod 4 is reset in time, the liquid inlet valve sleeve 6 and the large valve core 7 in contact with it form a metal hard seal, and at the same time, the inside of the large valve core 7 is in contact with the small valve core 8 that is unloaded by the pilot . The end of the small spool 8 forms a pressure recovery chamber through the spring 9 and the screw sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com