Grinding head of roasting plate grinding processing equipment

A kind of grinding processing and equipment technology, which is applied in the field of grilling plate grinding processing equipment for barbecue ovens, can solve the problems of poor surface effect of baking plate grinding and low grinding efficiency of horizontal surface grinders, so as to improve work efficiency, eliminate axial clearance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

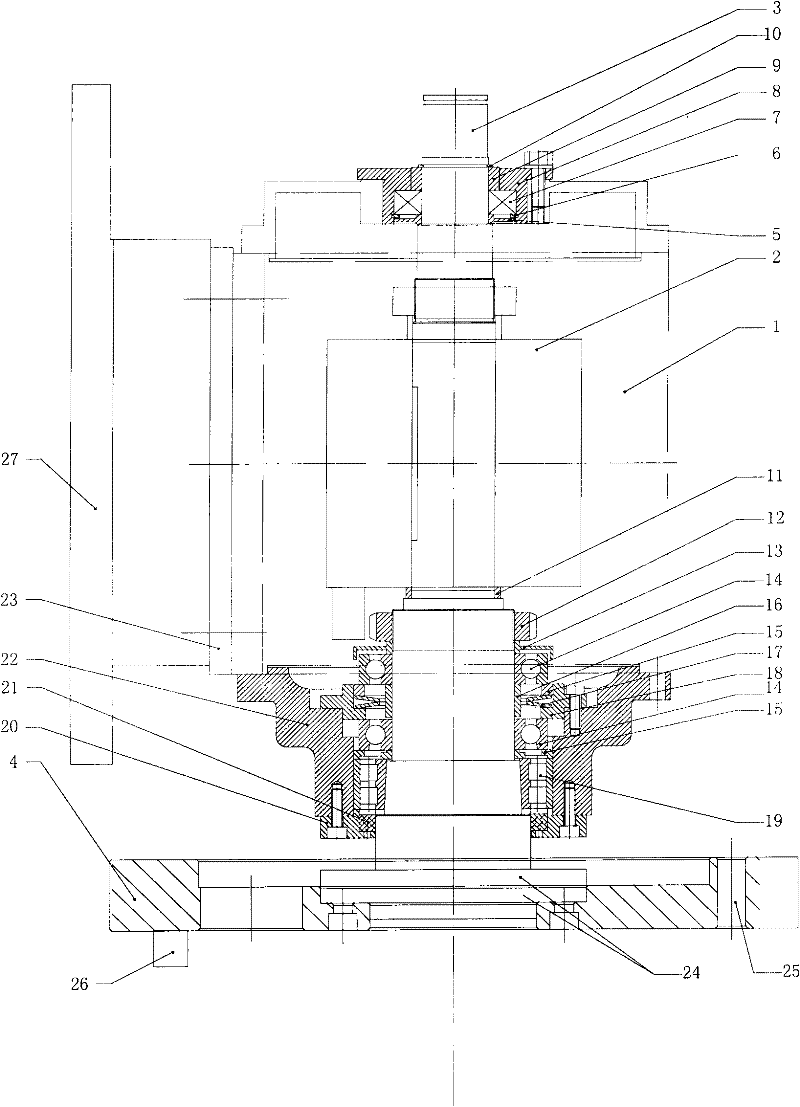

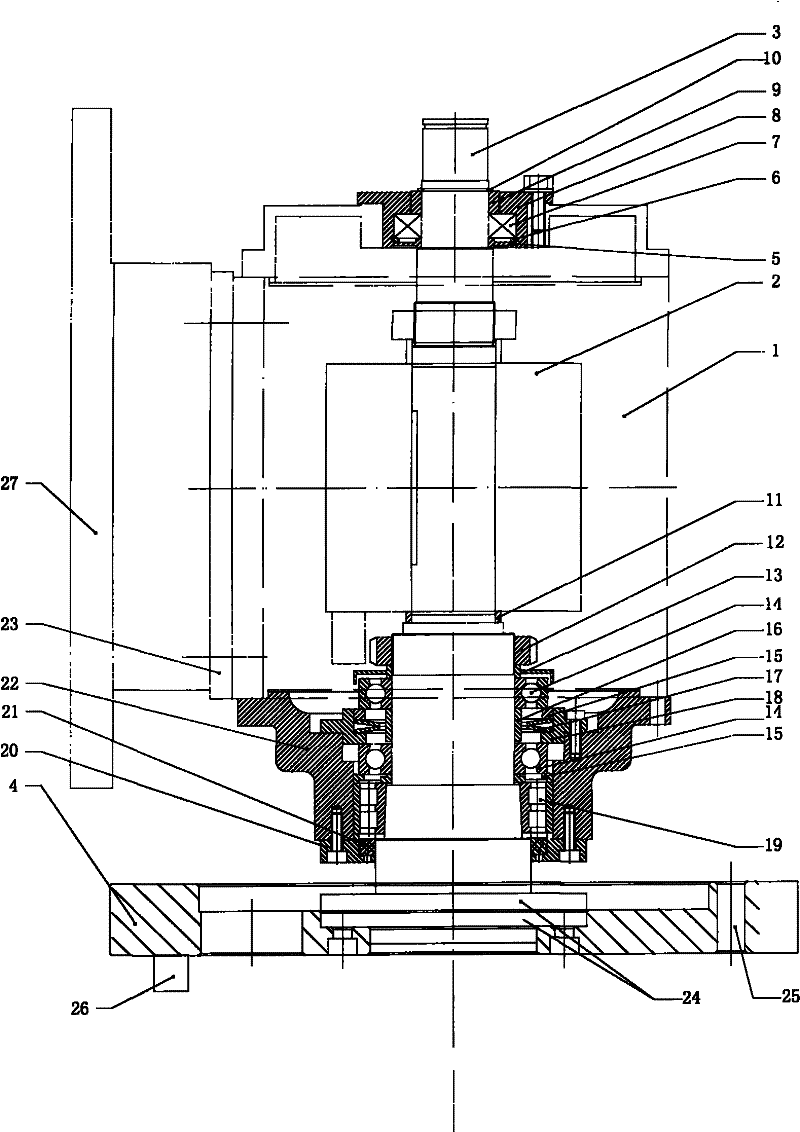

[0014] Such as figure 1 As shown, the grinding head of the baking plate grinding processing equipment in the preferred embodiment of the present invention includes a motor 1 , a rotor 2 , a main shaft 3 , and a grinding wheel disc 4 . The main shaft 3 is hollow, one end passes through the top fixing hole of the motor 1, and then covers an oil retaining plate 5, a hole retaining ring 6 and a rolling bearing 7, and then covers a bearing cover 8 and a dust retaining ring 9, and then uses a shaft retaining ring 10 fixed. The other end of the main shaft 3 passes through a locating ring 11 and is tightened by a round nut 12 cooperating with the thread on the shaft to fix the rotor 2 . Then, after the oil retaining plate 13 is covered on the shaft, a pair of angular bearings 14 are socketed. Adjusting washers 15 are installed below each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com