Tapered cylindrical membrane electrode for oxyhydrogen proton exchange membrane fuel cell

A technology of proton exchange membrane and fuel cell, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problem of close contact, affect the efficiency and life of the battery, and drop the working voltage of the battery, so as to facilitate maintenance and replacement Components, convenient temperature adjustment, enhanced leak-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

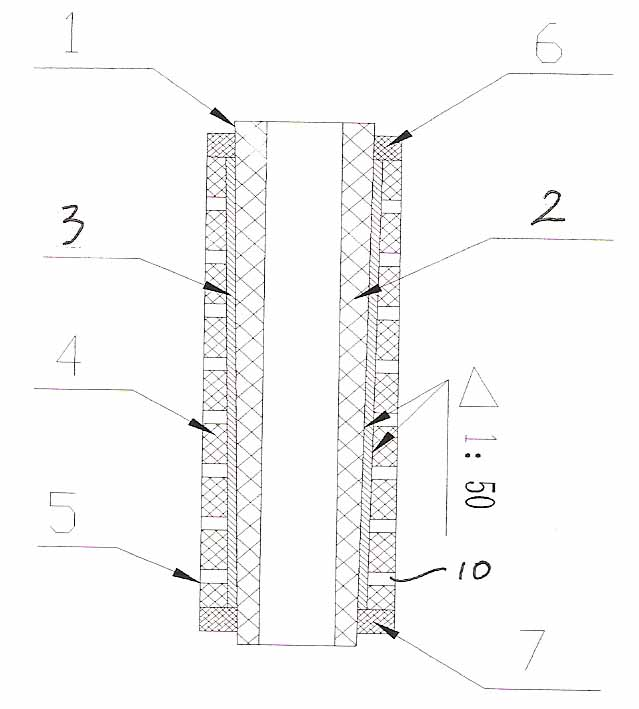

[0031] A tapered cylindrical membrane electrode for a hydrogen-oxygen proton exchange membrane fuel cell, which is composed of an anode 2, a composite membrane 3, and a cathode 4 on the inside and outside respectively, the anode is in contact with hydrogen, and the cathode is in contact with air; The composite membrane is composed of a proton exchange membrane (Nafion membrane) (including a catalyst layer and a diffusion layer). There is an output joint 1 at the anode plate, and a sealing ring 6 is set at the anode output joint to isolate the anode output joint from the composite membrane and the cathode. The bottom of the cathode output joint 5 is provided with a sealing ring 7; the sealing rings 6 and 7 at both ends have the inlet and outlet of hydrogen and oxygen respectively, and communicate with the channels of the anode and the cathode respectively.

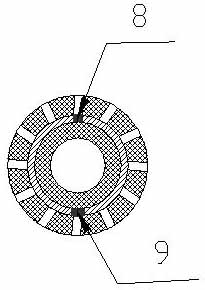

[0032] In the figure, 8 is a proton exchange membrane joint, and 9 is a cathode joint. The anode is conical, the composit...

Embodiment 2

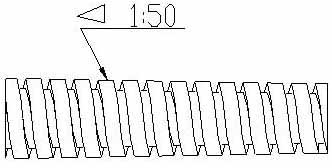

[0037]The anode is a solid rod-shaped body, and there are spiral grooves or grid grooves for passing hydrogen on the periphery of the rod-shaped body, the groove width is 1-3mm, and the groove depth is 0.5-2mm.

[0038] There are spiral grooves or grid grooves on the inner surface of the cathode tube wall, the groove width is 1-3mm, and the groove depth is 0.5-2mm. All the other are with embodiment 1.

[0039] The sealing rings at both ends respectively have the inlet and outlet of hydrogen and oxygen, and communicate with the channels of anode and cathode respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com