Integral detection cabinet with battery cabin

A technology of battery detection and battery compartment, which is applied to the parts of electrical measuring instruments, measuring electricity, measuring devices, etc., can solve problems such as unfavorable battery heat dissipation, affecting test results, battery damage, etc., to prolong the service life of mechanical positioning, improve the Heat dissipation capacity, the effect of preventing the impact of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

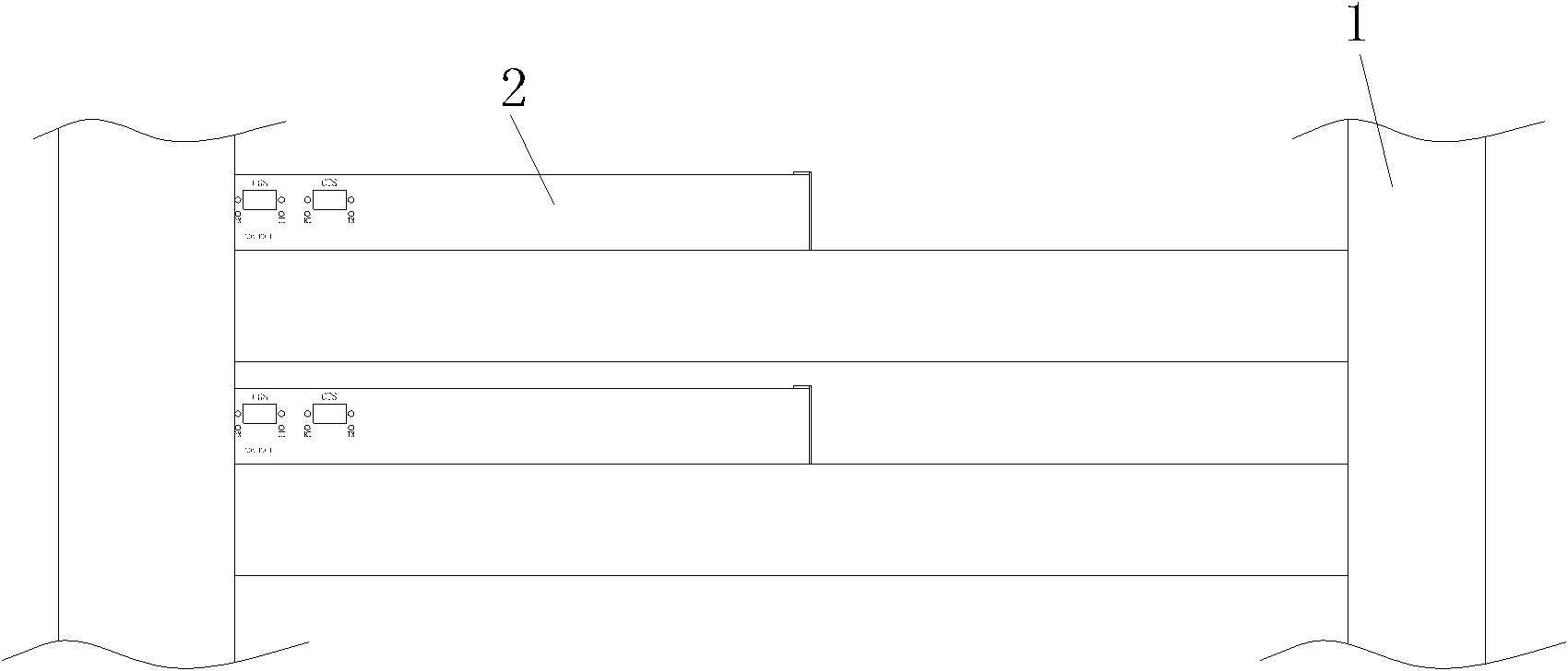

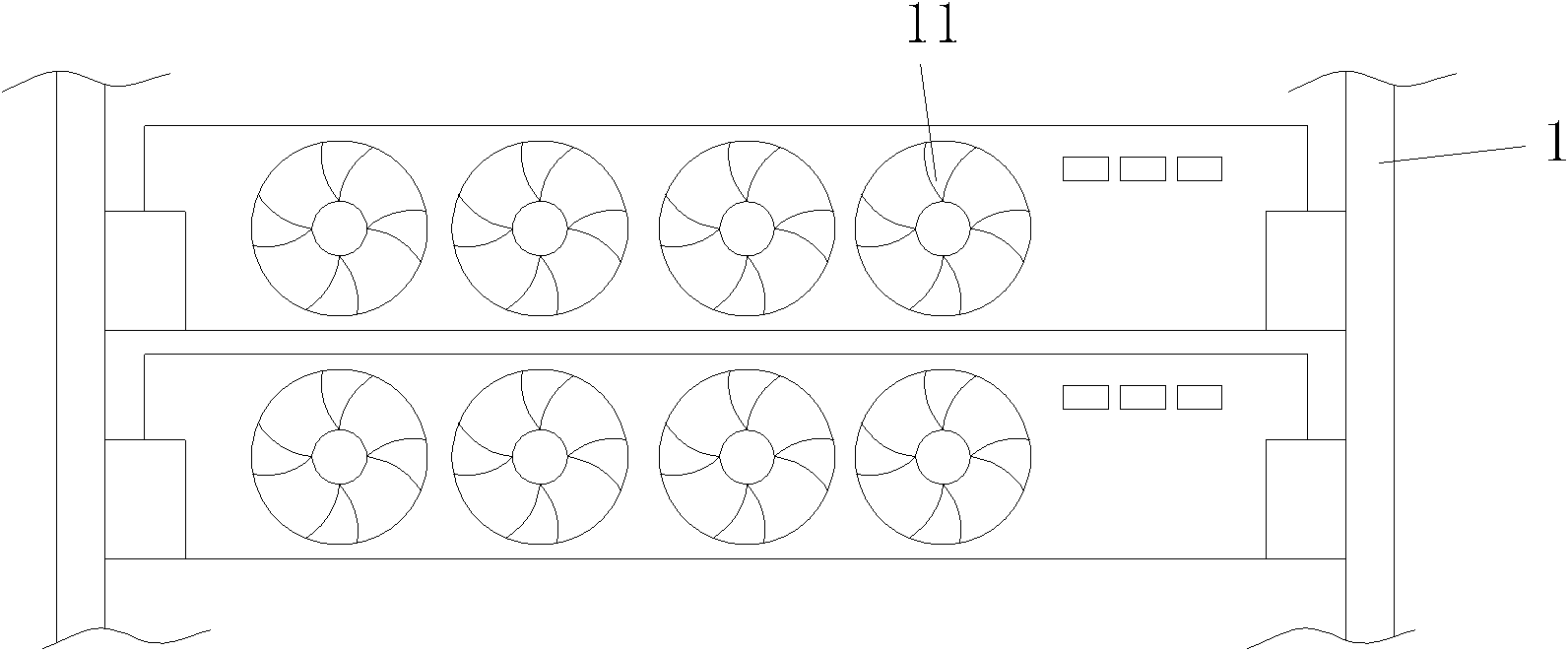

[0023] The present invention will be further described in detail below with reference to the drawings and embodiments. Such as figure 1 with figure 2 As shown, in the integrated detection cabinet with battery compartment of the present invention, the cabinet frame 1 is composed of four uprights and upper and lower panels. The rectangular cabinet frame 1 is provided with drawers arranged in layers from top to bottom. The battery detection device 2 has a push-pull structure. The shape of the battery detection device 2 is rectangular. The front end of the battery detection device 2 is connected with a battery compartment 3 integrated with the battery detection device 2 and on the same level. The battery compartment 3 has no cover on the top. The rectangular box body is made of a metal material with a thickness of 1.0-1.2mm, the exterior is sprayed, and the interior is insulated with PVC coating. The front-to-back depth dimension of the battery detection device 2 is shorter than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com