Nanometer-resolution total-reflection differential micrometric displacement measurement method and device

A total reflection and differential technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of expensive system, complicated adjustment, limited resolution, etc., to achieve a simple measurement system, overcome optical power fluctuations, and improve sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

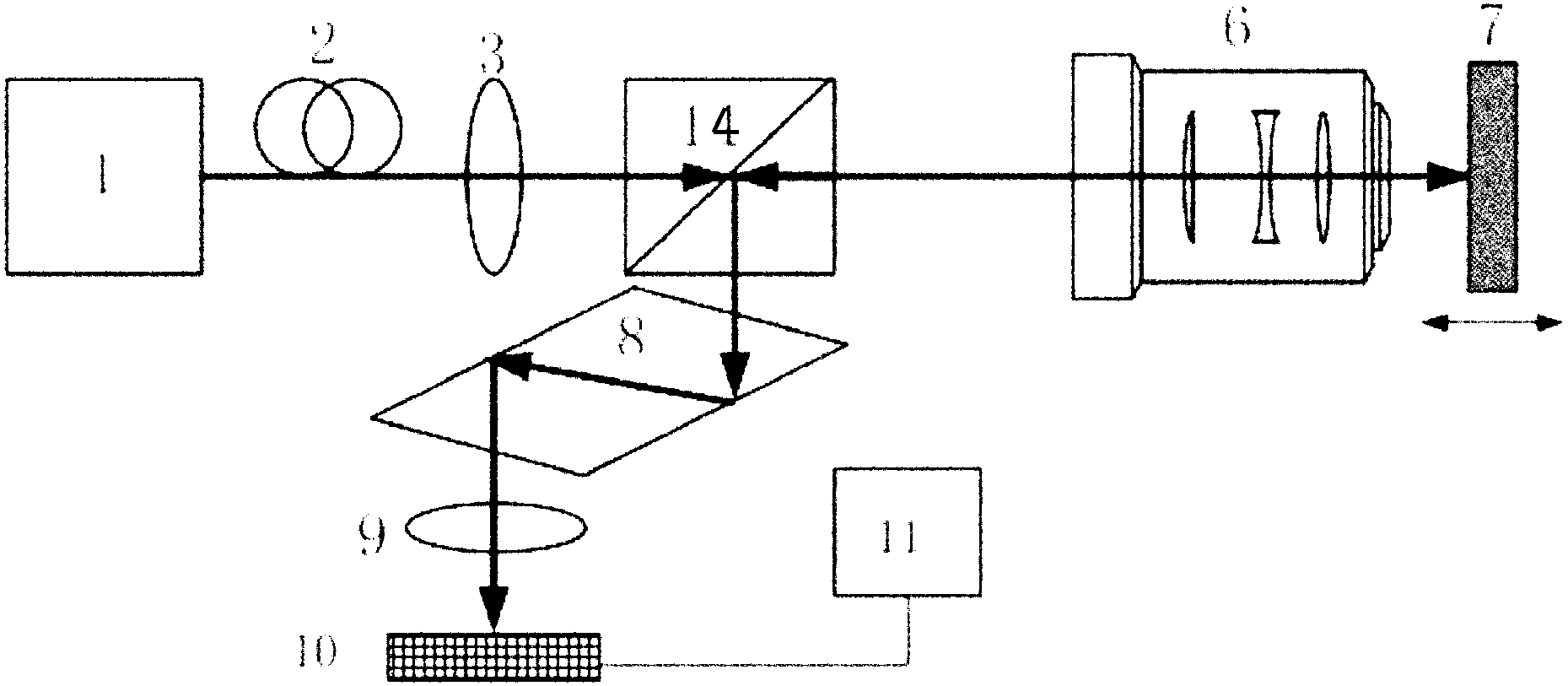

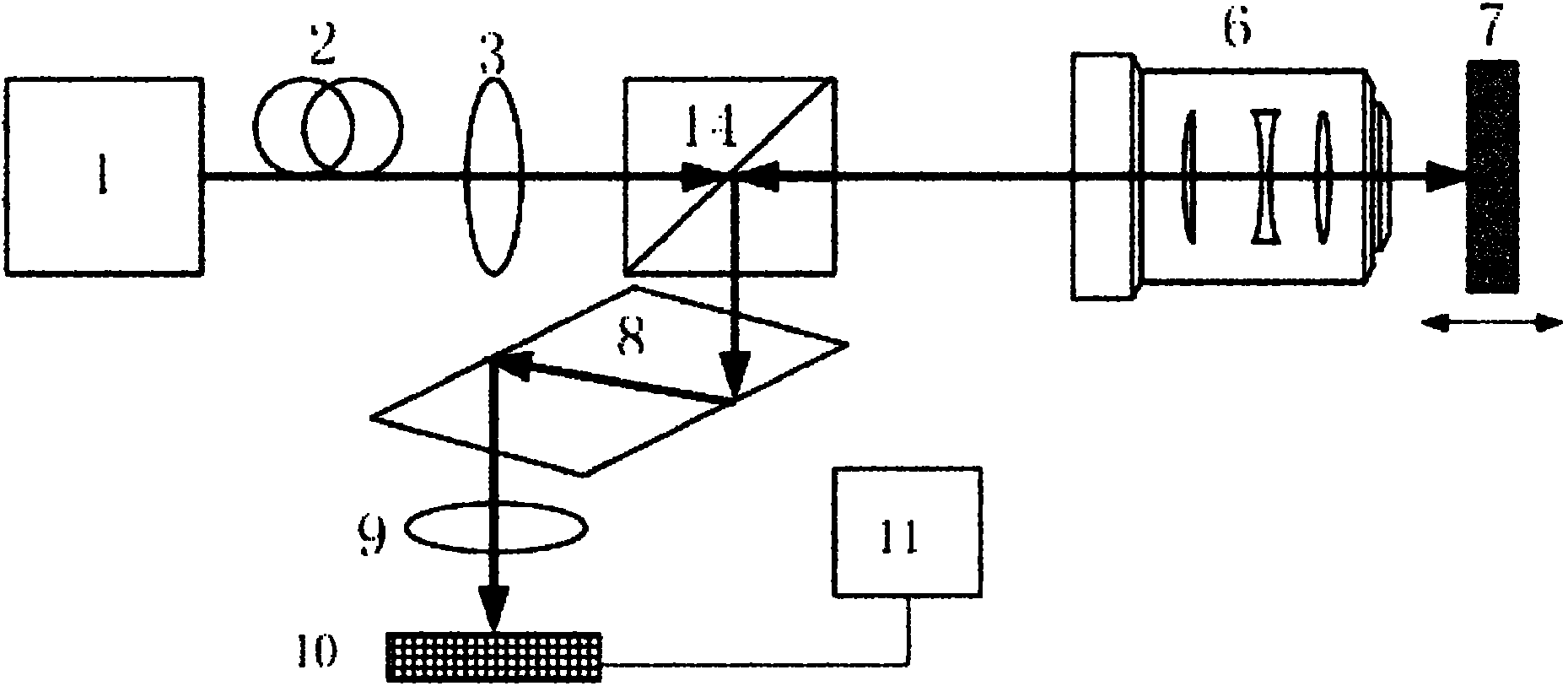

[0034] Such as figure 1 As shown, a device for measuring nanometer-resolution total reflection differential micro-displacement, including: a laser 1, a single-mode fiber 2, a collimator lens 3, a depolarizing beam splitter 14, a microscopic objective lens 6, a target mirror 7, an orthorhombic Prism 8 , convex lens 9 , differential detector 10 , drive and display unit 11 .

[0035] The laser 1, the single-mode fiber 2 and the collimating lens 3 constitute the first component group in sequence, and the depolarization beam splitter 14 is the second component group, and the first component group and the second component group are sequentially located on the optical path of the light emitted by the laser 1 The microscopic objective lens 6 is the third component group, and the measured target lens 7 is located on the first transmission light path of the depolarization beam splitter 14 successively; the rhombic prism 8, the convex lens 9, the differential detector 10 and the drive an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com