Rebar planting-free formwork erecting method for masonry construction and device thereof

A formwork support method and masonry technology, which are applied to the connection of formwork/formwork/work frame, the preparation of building components on site, and construction, etc., can solve the problem of environmental pollution, formwork loss and low turnover rate of planting reinforcement drilling. and other problems, to achieve the effect of improving the seismic and crack resistance performance and reducing the loss of wood formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

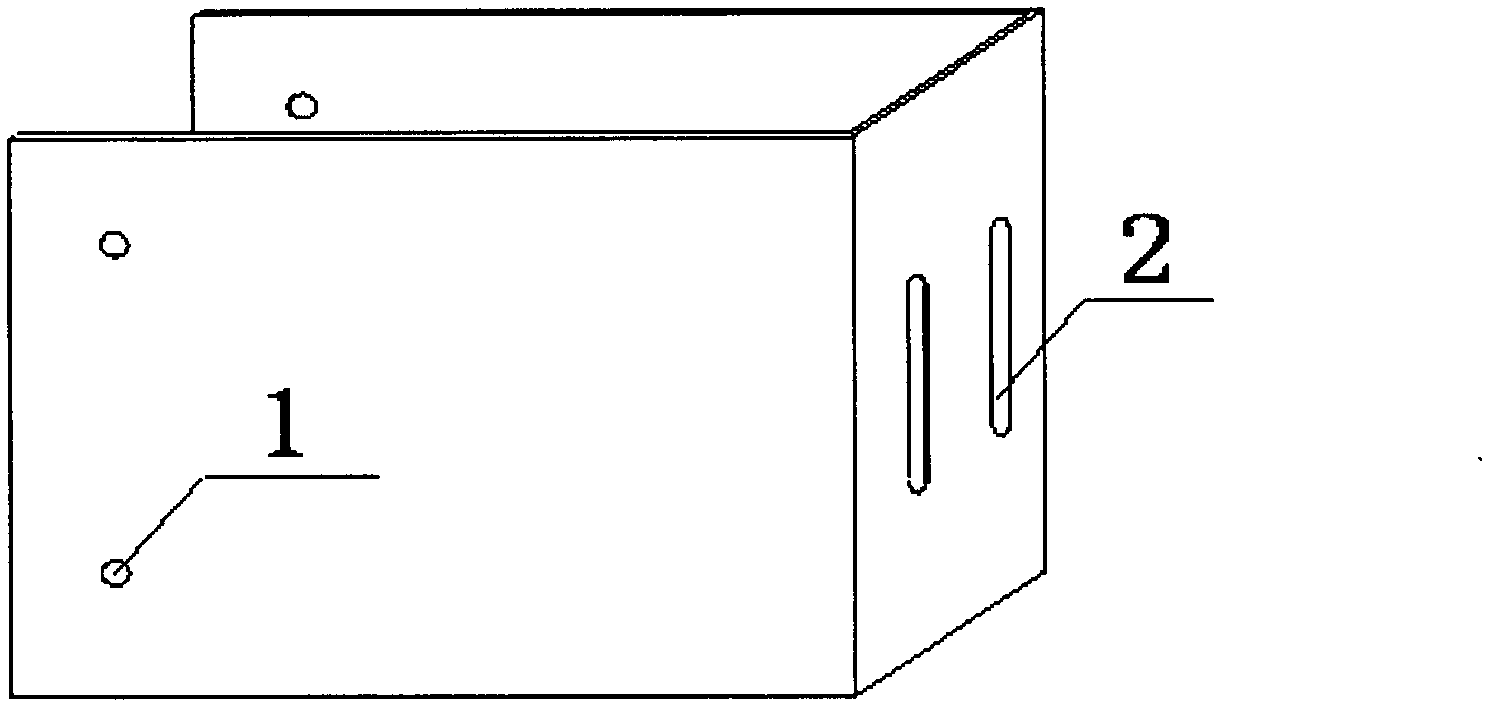

[0014] like figure 1 As shown, the masonry construction reinforcement-free formwork support device of the present invention is U-shaped, and is welded by steel plates according to the size of the masonry. Its front panel is provided with two tie bar perforations 2, and the two side panels are respectively provided with mutual symmetry. The two pull-screws are perforated 1.

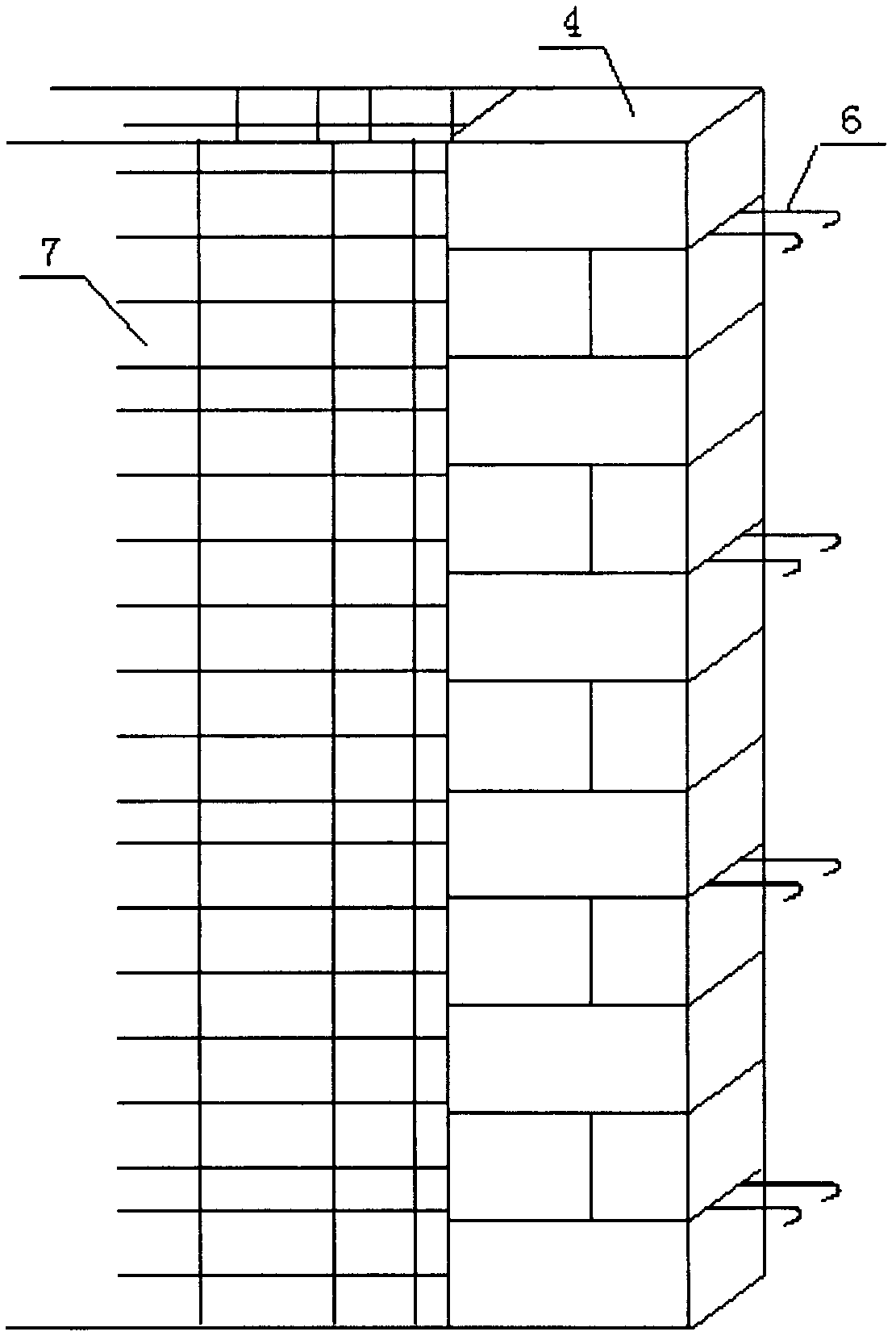

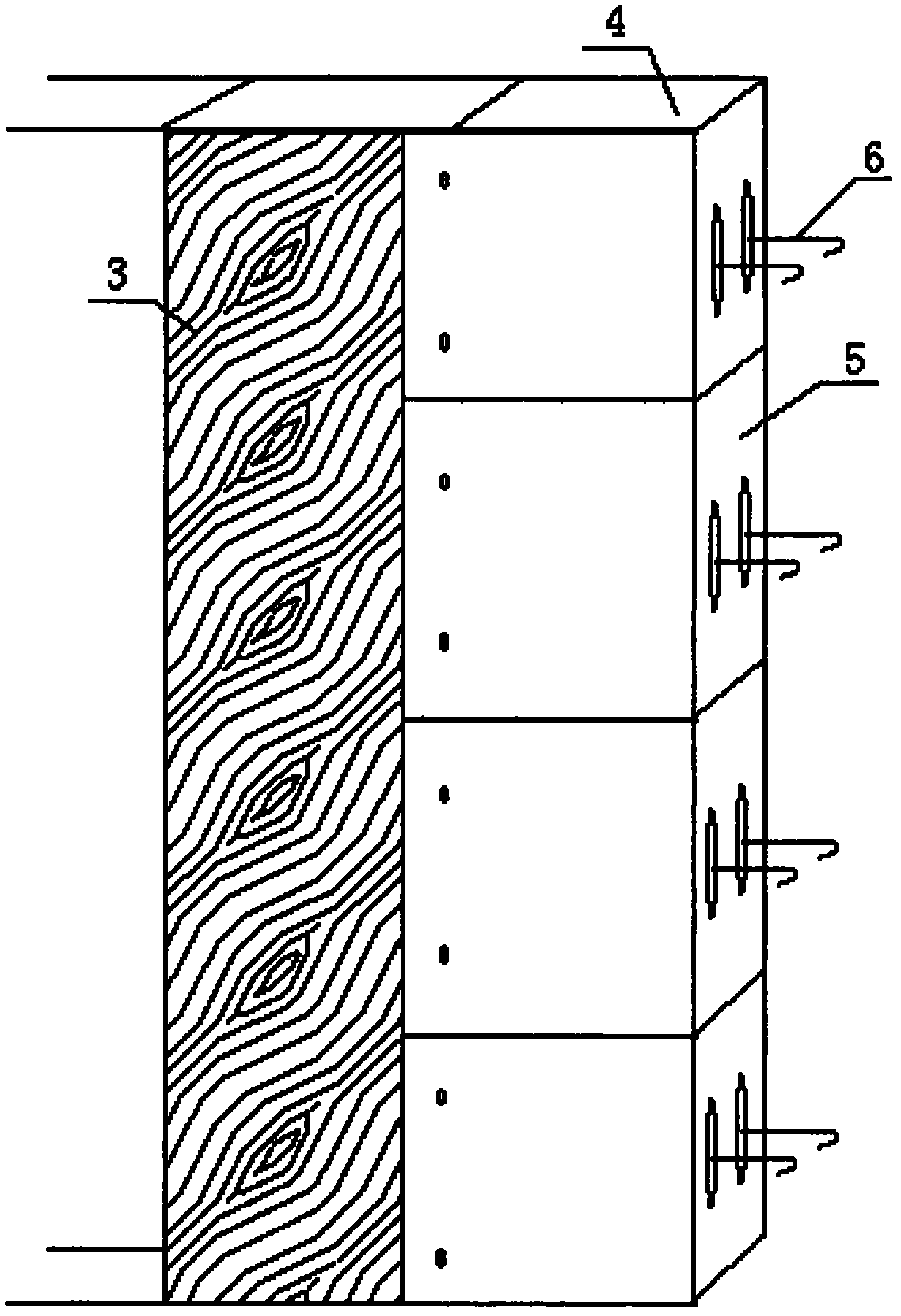

[0015] Figure 2 to Figure 4 It shows the formwork support method for masonry construction using the above-mentioned formwork device: before concrete pouring, the single-skin masonry 4 is built close to the wall or column reinforcement 7, and the tie bars 6 are placed on the masonry according to the design spacing requirements. Inside the body ash crevice (see figure 2 ), and then use the formwork device 5 and the wooden formwork 3 of the concrete wall or column to close the single-skin masonry 4, tie bars 6, wall or column reinforcement 7 together (see image 3 and Figure 4 ), wherein the tie bars 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com