Method for synthesizing particle reinforced aluminum-based composite under high-intensity ultrasonic field and pulsed electric field

A pulsed electric field and composite material technology, which is used in the field of synthesizing particle-reinforced aluminum matrix composites under high-energy ultrasound and pulsed electric field, can solve the problems of coarse particle dispersion, unevenness, low reaction efficiency, etc., achieve simple and safe operation, and increase energy fluctuations. , the effect of precipitation growth promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Prepared under the coupling action of high energy power ultrasonic field and pulsed electric field (Al 3 Zr (s) + ZrB 2(s) ) Particle-reinforced Al-based composites

[0042] Raw material: base metal: pure Al; reaction salt: K 2 ZrF 6 +KBF 4 Powder (mass ratio 6.2:7.8), refining degassing agent and slag removal agent;

[0043] The preparation process is divided into two steps:

[0044] (1): Metal smelting and powder preparation:

[0045] 10Kg of pure Al is melted in a 30kW resistance furnace and heated up to 900°C for degassing and slag removal; all reagents used are fully dried at 250°C, of which K 2 ZrF 6 +KBF 4 , ground into fine powder (particle size less than 100 mesh), K 2 ZrF 6 +KBF 4 The weight of the powder added is 20% of the weight of the metal.

[0046] (2): In situ reaction synthesis to prepare composite material melt:

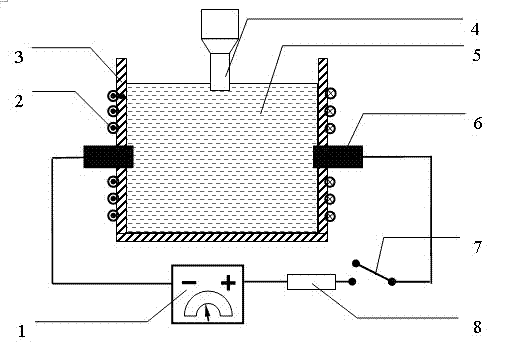

[0047] The experimental device used in this example is figure 1 As shown, the molten metal that ha...

Embodiment 2

[0058] Example 2: Preparation under the coupling action of high energy power ultrasonic field and pulsed electric field (Al 3 Zr (s) + Al 2 O 3(s) ) Particle-reinforced Al-based composites

[0059] Raw materials: base metal: pure Al; solid powder: industrial zirconium carbonate (Zr(CO 3 ) 2 ) powder, refining degassing agent and slag removal agent;

[0060] The preparation process is divided into two steps:

[0061] (1): Metal smelting and powder preparation:

[0062] 10Kg of pure Al is melted in a 30kW power frequency aluminum melting furnace and heated up to 900°C, degassed and slag removed; all reagents used are fully dried at 250°C, of which Zr(CO 3 ) 2 Grind into fine powder (particle size less than 200 mesh), weighed for later use, Zr(CO 3 ) 2 The added weight is 20% of the metal weight.

[0063] (2): In situ reaction synthesis to prepare composite material melt:

[0064] The experimental device used in this example is figure 1 As shown, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com