Novel high-concentration emulsified wastewater deemulsification device

An emulsified wastewater and high-concentration technology, which is applied in the direction of light water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor long-term operation stability, large consumption of chemicals, and reduction of demulsifiers, etc., to achieve long-term cycle Stable operation, complete oil-water separation, and the effect of reducing the amount of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

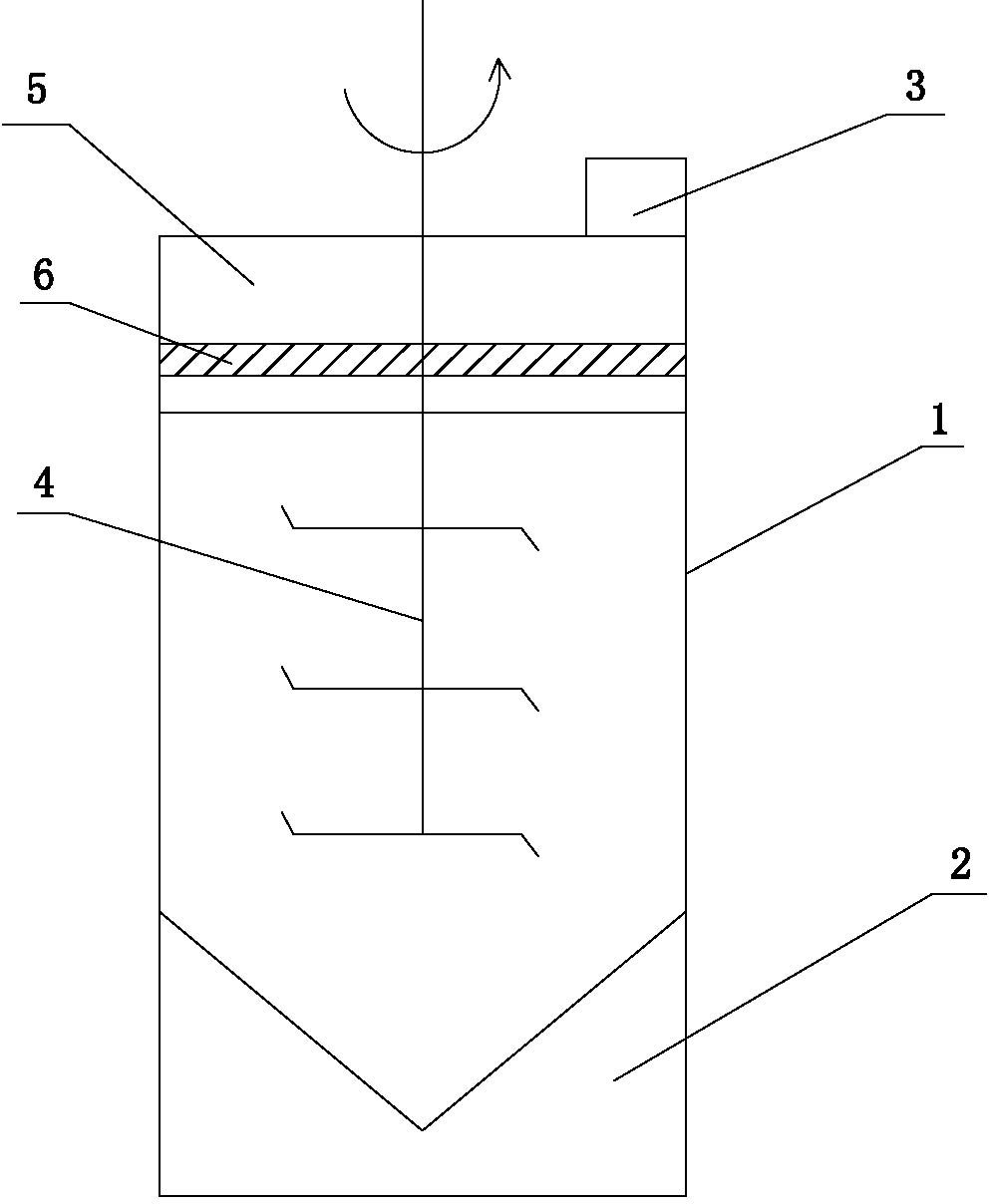

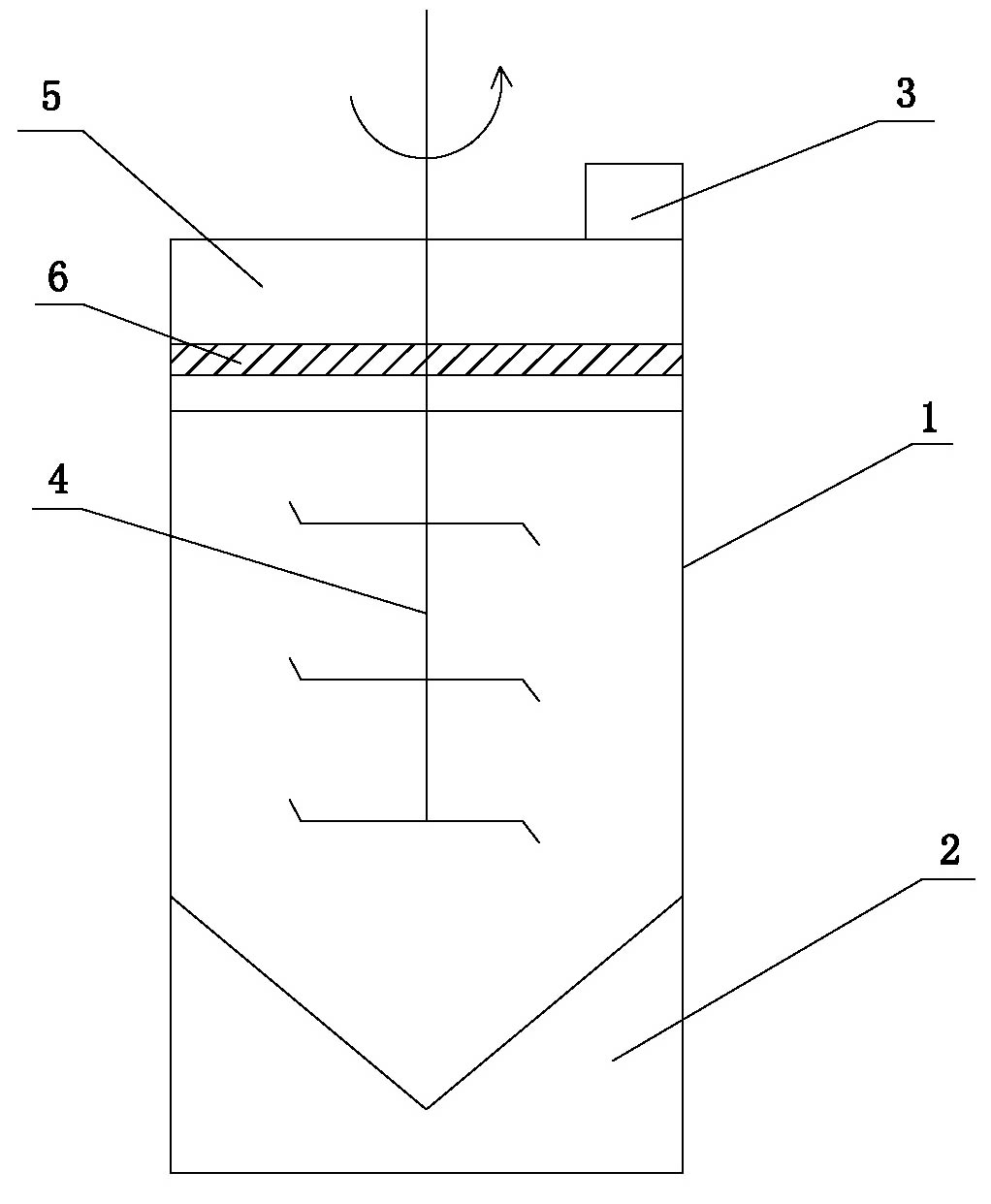

[0015] Below in conjunction with accompanying drawing, the present invention will be further described:

[0016] like figure 1 As shown, the microwave generator 2 of the present invention is arranged at the bottom of the demulsification tank 1, and the dosing pump 3 is provided on the demulsification tank 1, and the mixer 4 is arranged in the demulsification tank 1, and the demulsification tank 1 top is provided with An oil collecting chamber 5, in which a rotating oil suction scraper 6 is arranged. The oil-absorbing scraper 6 is made of polyurethane or epoxy resin. The purpose of the oil-absorbing scraper 6 is to absorb oil when the oil is dispersed, and to collect the oil when the oil is separated out. At the same time, the stirring shaft of the mixer 4 is provided with two or three stirring blades, which are vertically arranged and evenly installed on the stirring shaft, so that the reaction time of demulsification can be reduced and the demulsification efficiency can be i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| demulsification efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com