Multifunctional nozzle used for wet desulphurization and dust removal of industrial flue gas

A technology for wet desulfurization and industrial flue gas, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of reduced desulfurization efficiency and uneven diffusion of liquid at the nozzle outlet, and achieves enhanced potential energy and reduced rollback. , enhance the effect of penetrating energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

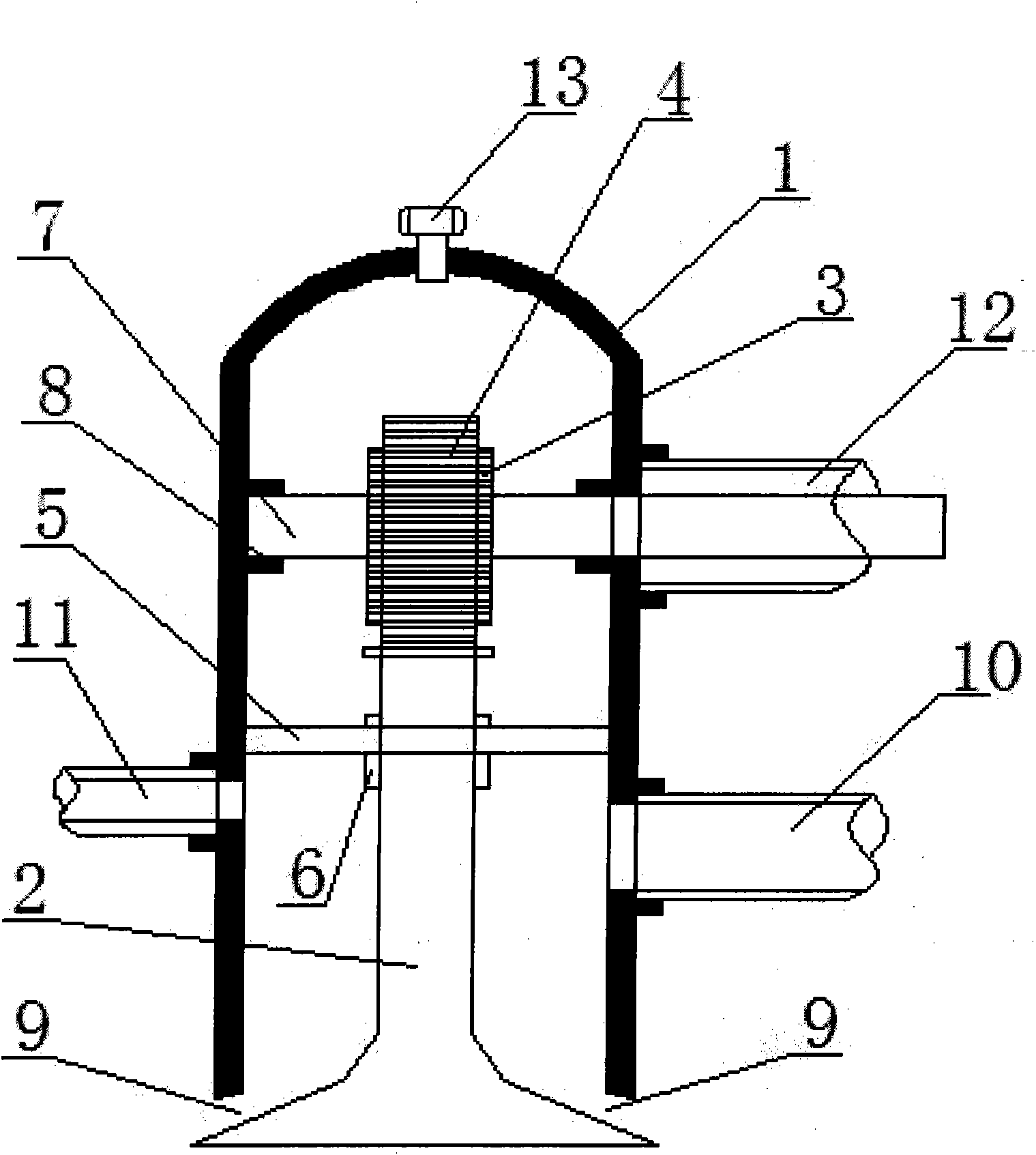

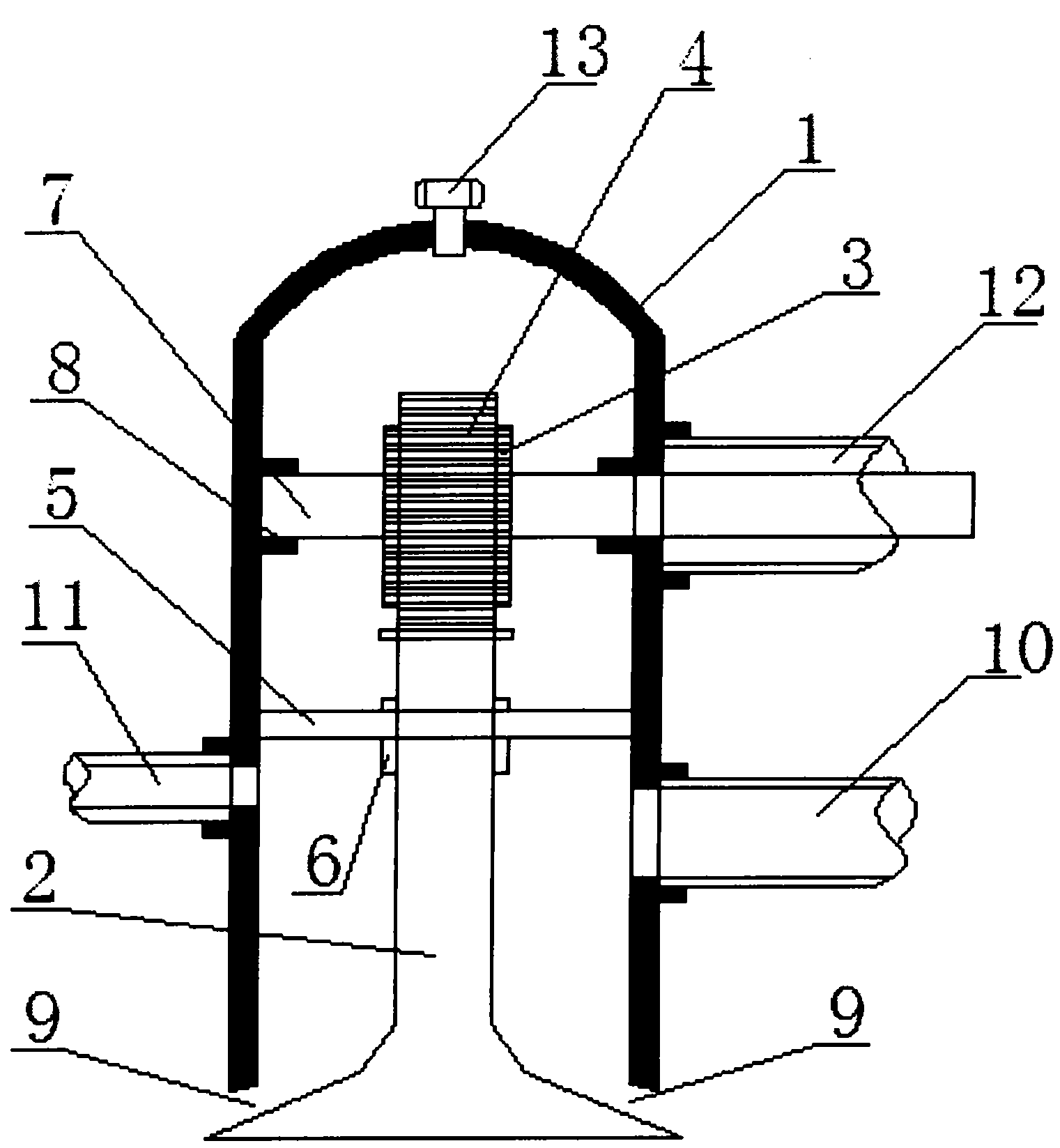

[0014] The present invention and its specific implementations will be described in further detail below in conjunction with the accompanying drawings.

[0015] Referring to the accompanying drawings, the present invention includes a housing, which is characterized in that: the housing 1 is provided with an adjustment rod 2, one end of the adjustment rod is provided with a rack 4 meshing with the gear 3, the other end is conical, and the housing 1 is also provided with a partition 5 and a seal ring 6 that separate it into upper and lower cavities, and the transmission shaft 7 passes through the gear 3 and is connected with the bearing 8 in the shell.

[0016] The adjusting rod 2 passes through the central hole of the dividing plate 5 and the sealing ring 6, and is controlled by the transmission shaft 7 and can move down and down.

[0017] Adjust the nozzle gap 9 through the movement of the transmission shaft 7 in the nozzle housing 1 to ensure that the water film has a pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com