Large-span prestressed concrete beam plate as ventilating channel and ventilating channel system

A ventilation channel and prestressing technology, which is applied in the direction of ventilation system, girder, space heating and ventilation, etc., can solve the problems of not exceeding a larger span, complex ventilation pipeline facilities, and light weight, etc., to achieve simple structure, convenient construction, The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]As shown in Figure 8, the position of the ventilation channel hole 2 opened on the rib plate of the hollow single T beam slab or multi-T box girder 1 should be in the low shear section 15 and the upper wing outside the shear zone at both ends. Below the slab compression area 16 and above the prestressed reinforcement area 17, if the prestressed tendon of the beam slab is curved tension, it should also avoid the prestressed reinforcement curved tension area 18, and set the rubber type membrane on the ventilation channel hole 2 Leave the grouting port 19 on the fetal membrane. Conventional strengthening measures can be taken for the ribs of the ventilation channel holes, including strengthening the steel ribs around the holes, thickening or increasing the concrete grade, or adding or thickening steel pipes matching the holes, so as to improve the bending resistance of the rib plane of the ventilation channel holes Ability to reinforce the weakened section of the opening. ...

Embodiment 2

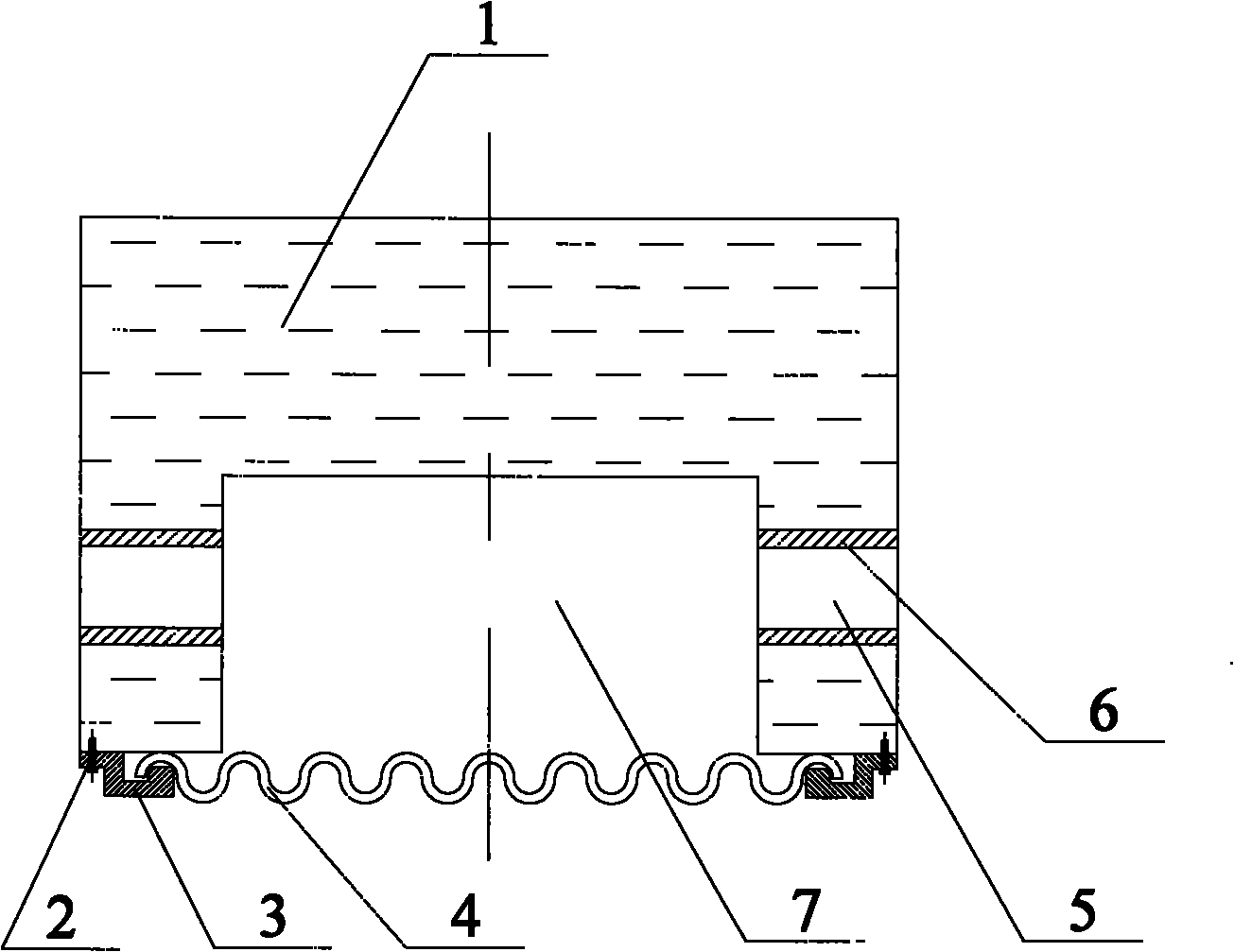

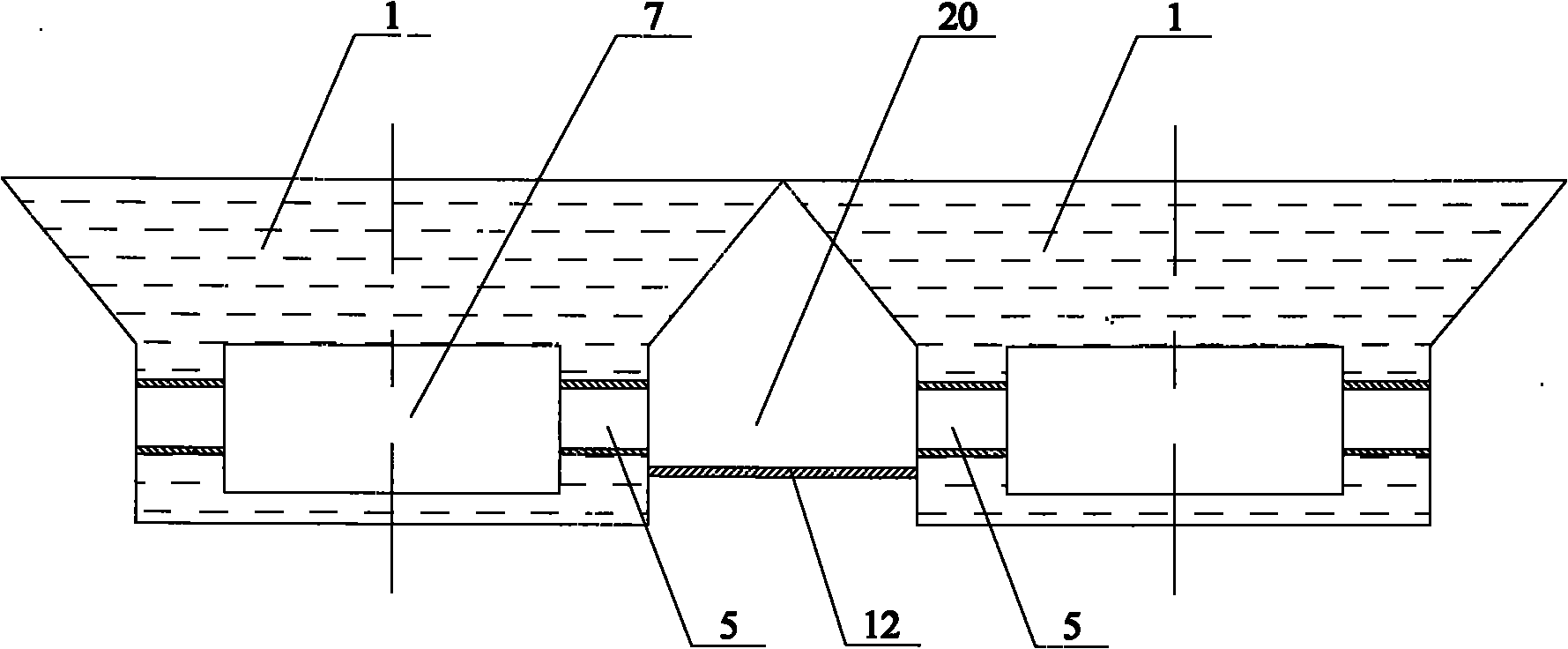

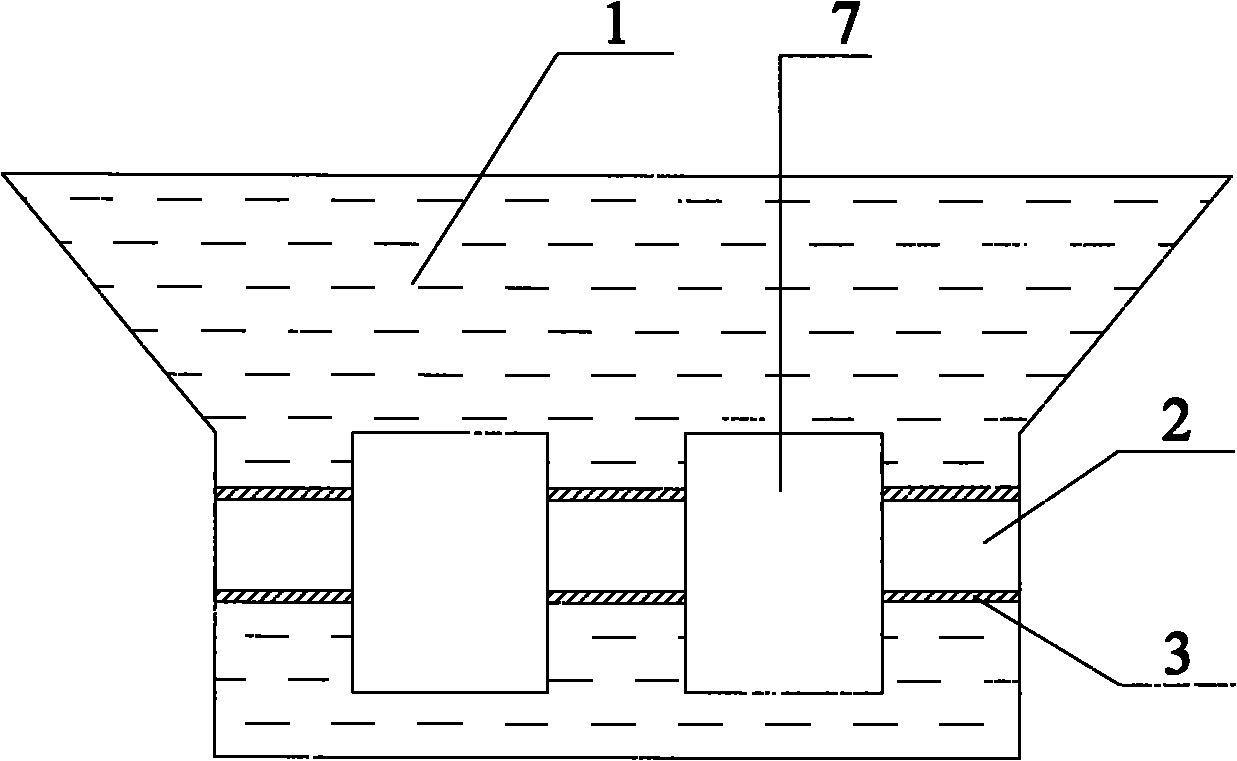

[0033] Such as figure 1 As shown, on the basis of the embodiment, the grooved plate 1 is also provided with a sealing plate 4, if the hook 3 and the fastener 2, the fastener 2 fixes the hook 3 to the grooved plate 1 respectively. On the bottom surface of the two ribs, the sealing plate 4 is fixed on the hook 3 and sealed between the sealing plate 4 and the lower surfaces of the two ribs of the channel plate 1, and then the two ends of the lower sealing plate and the beam plate are sealed. Between the roof or the top of the beam slab formed by construction and the two ribs or sides. During construction, fix the fastener 2 on the embedded part on the bottom surface of the rib plate of the channel plate 1, then fix the sealing plate 4 on the bottom surface of the rib plate of the channel plate 1, and finally fix the sealing plate 4 and the channel plate 1 Seal the gap between the bottom surfaces of the ribs, and seal the two ends of the lower sealing plate or between the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com