Multi-head machine thread stand of computerized embroidery machine

A technology for embroidery machines and multi-head machines, which is applied in the field of multi-head machine thread racks, which can solve the problems of multiple threads being entangled or knotted, paralleled, and entangled, and achieve the effect of convenient threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

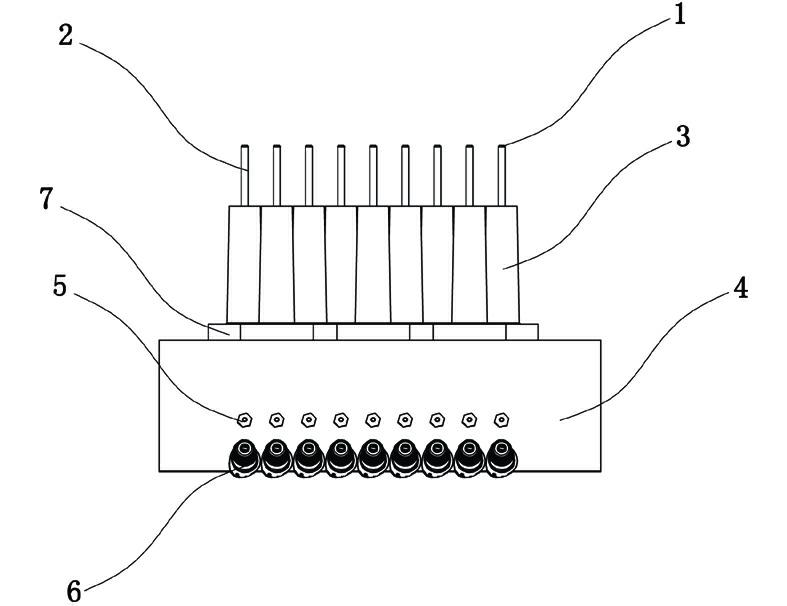

[0022] Embodiment 1: as figure 2 As shown, a multi-head thread frame of a computerized embroidery machine includes a base plate 4. The base plate 4 has a horizontal plane in the horizontal direction and an inclined plane connected to one side of the horizontal plane and opens obliquely downward and outwardly. The base plate 4 is provided with Multiple sets of thread racks including thread spool 3, thread seed 1 and thread gripper 6.

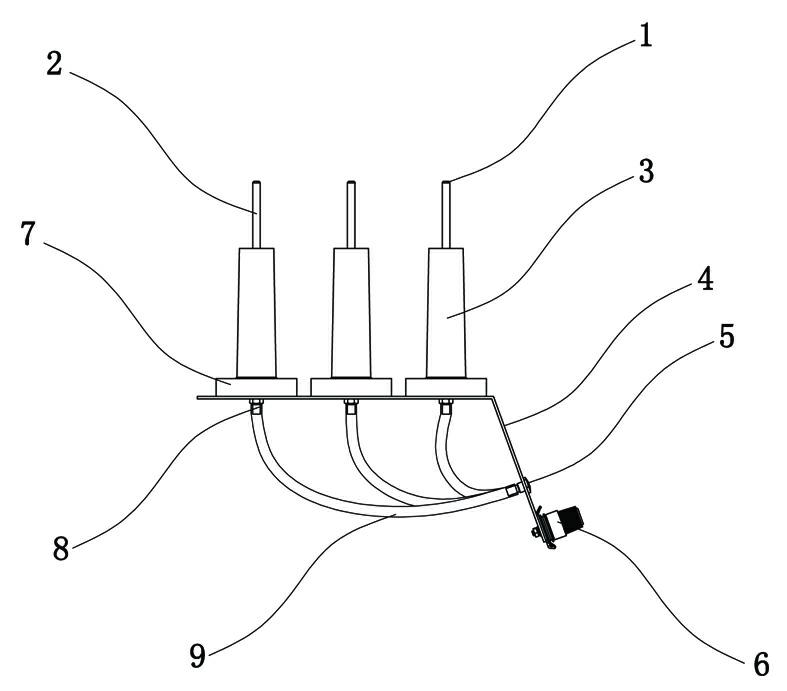

[0023] Such as image 3 As shown, the single group of wire racks includes a wire-passing pipe 2 arranged upright on a horizontal plane above the substrate 4, and a through hole 8 is provided on the substrate 4 where the lower end of the wire-passing pipe 2 is connected to the substrate 4. The pipelines of the line pipe 2 are connected, and a thread nut is installed on the through hole 8 . The upper end of the thread pipe 2 is provided with a thread seed 1 . A thread gripper 6 is provided on the lower inclined surface of the substrate 4, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com