Winding shaft

A technology of winding shaft and spindle, applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problems of not complying with low-carbon environmental protection, inability to tighten, and paper scraps falling out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

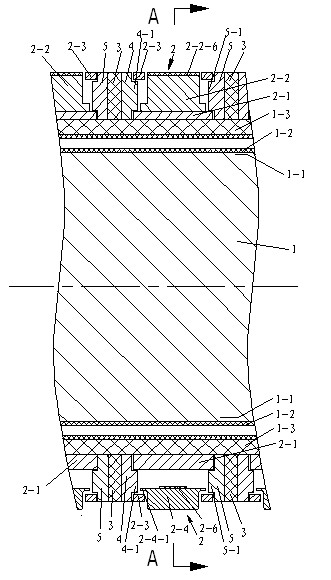

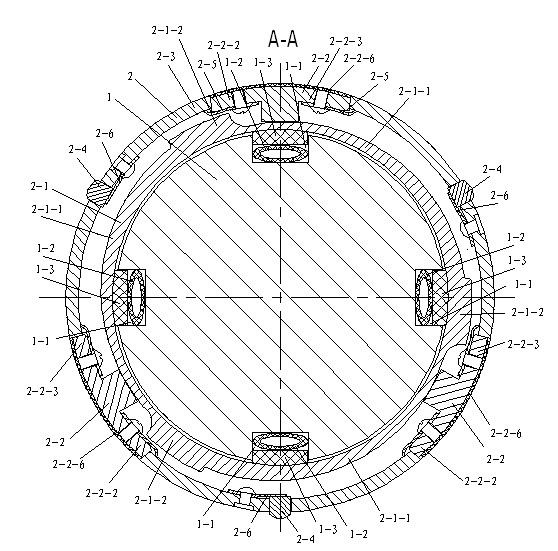

[0017] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

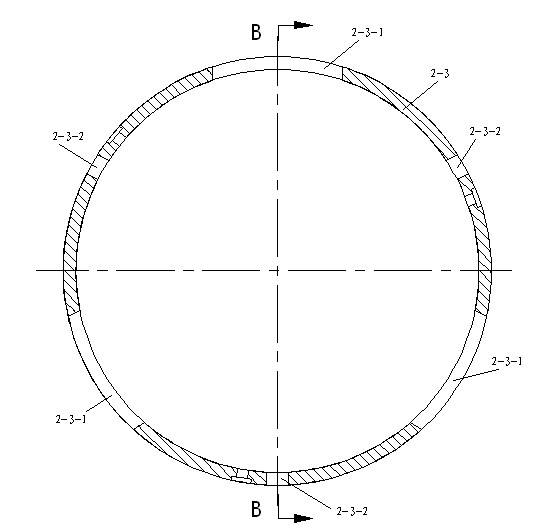

[0018] As shown in 1 to 8, a winding shaft is composed of a plurality of expansion rings 2 mounted on the main shaft 1 in series, and the expansion rings 2 include a guide seat 2-1 and a plurality of arc-shaped sliders 2-2 and a plurality of friction parts 2-4, the guide seat 2-1 is set on the main shaft 1, the left side of the guide seat 2-1 is fixedly connected with the first annular cover plate 4, and the right side is fixedly connected with the second annular cover plate 5, There are friction rings 3 between adjacent expansion rings 2, and the friction rings 3 are set on the main shaft 1. There are a plurality of axial grooves 1-1 on the outer periphery of the main shaft 1, and there are gas-filled tubes 1 in the axial grooves 1-1. -2 and the friction strip 1-3, the inflation tube 1-2 is located at the bottom of the axial groove 1-1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com