Special symmetric flange structure piece

A symmetrical and component technology, applied in the direction of mechanical equipment, fixtures, etc., can solve the problems of troublesome assembly operation, low assembly efficiency, and difficult to meet the requirements of assembly connection tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

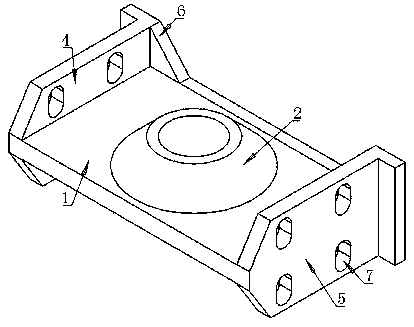

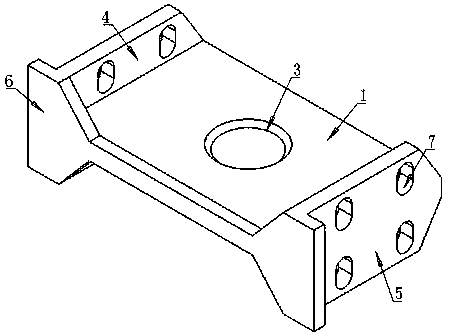

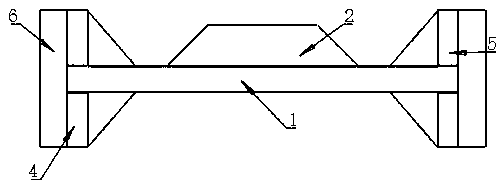

[0018] Such as Figure 1 to Figure 7 As shown, a special symmetrical flange structure, the parts are left and right symmetrical structures, so that the structural strength of the parts is higher, and it is more convenient to use. It uses the side fixing method to fix the flange structure, so that It makes assembly more convenient, and the firmness of assembly is also more reliable, which makes it more tightly connected with mechanical equipment, and can ensure the stability of mechanical equipment when in use. In addition, corresponding reinforcement structures are provided at the positions where the structural parts are connected, so that the overall strength of the parts is more reliable and safer during use. It includes a rectangular main body assembly base 1, and the upper center of the main body assembly base 1 is provided with a tapered assembly sealing boss 2, which can be better assembled and connected with mechanical equipment, and the sealing performance of the assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com