High-imitation manual tea leaf fixing machine

A technology for a greening machine and tea leaves, which is applied in the direction of tea treatment before extraction, etc., can solve the problems of reduced use of the greening machine, low product quality, heating of tea leaves, uneven stirring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

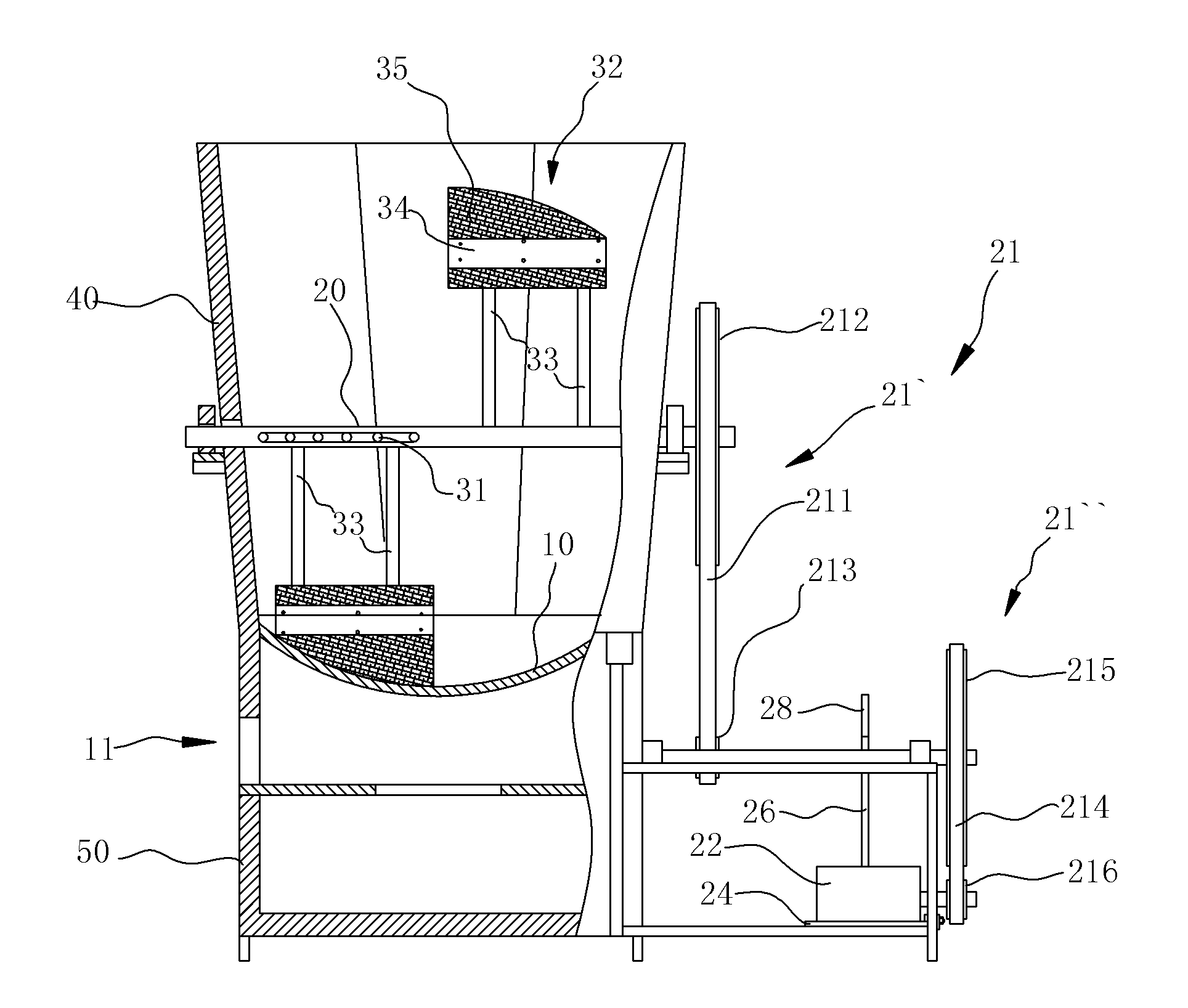

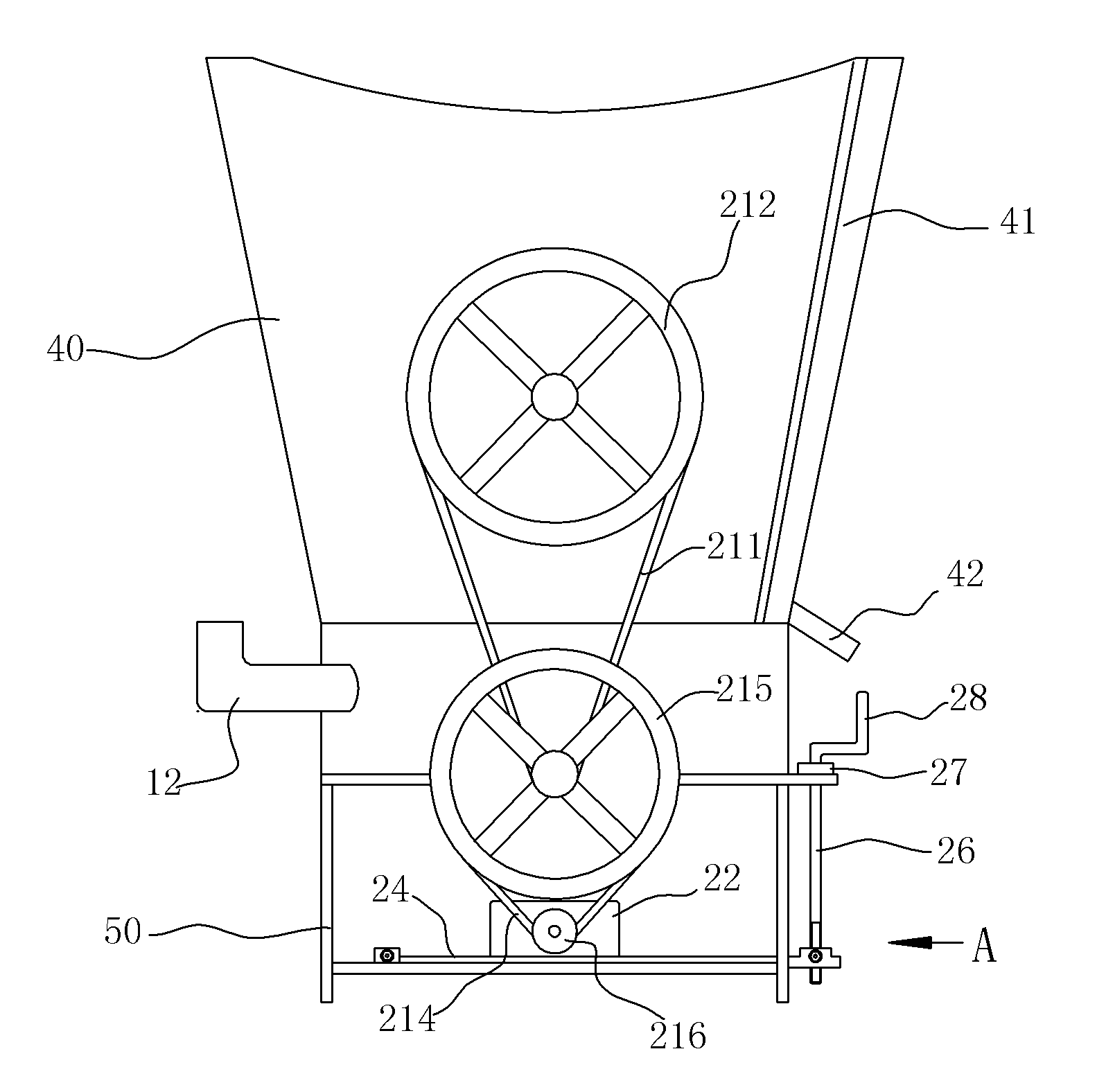

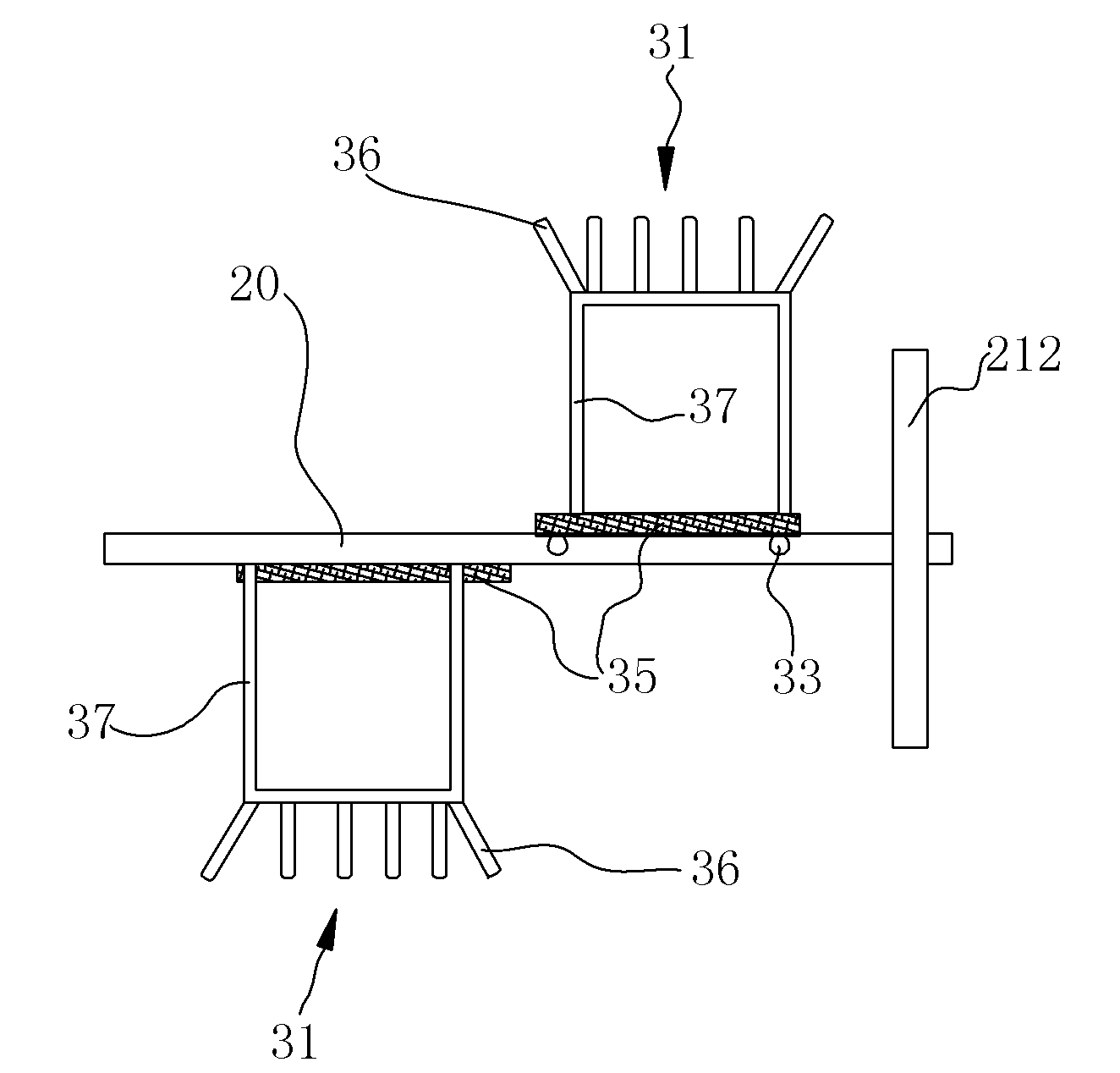

[0013] Such as Figures 1 to 3 A high imitation hand-made tea greening machine shown includes a round pot 10 and a heating device 11 for heating the round pot 10. A rotating shaft 20 is arranged in the middle of the round pot 10, and the rotating shaft 20 is driven by a driving device 21. The axial length direction of the rotating shaft 20 Roughly parallel to the mouth surface of the round pot 10 , a turning part is arranged on the rotating shaft 20 , one end of the turning part is connected with the rotating shaft 20 , and the end surface of the other end is arc-shaped and fitted to the inner wall of the round pot 10 . That is to say that the rotating shaft 20 is fixed and driven by any prior art, and then the rotating shaft 20 can be rotated to drive the stirring parts. With the movement of the rotating shaft 20, the tea leaves can be stir-fried.

[0014] When the tea leaves are stir-fried, since any part of the round pot 10 has a downward arc, the tea leaves turned up by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com