Device for variable adjustment of timing of gas exchange valves of internal combustion engine

A technology for internal combustion engines and ventilation valves, which is applied in valve devices, mechanical equipment, engine components, etc., can solve problems such as increasing the complexity of cylinder heads and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

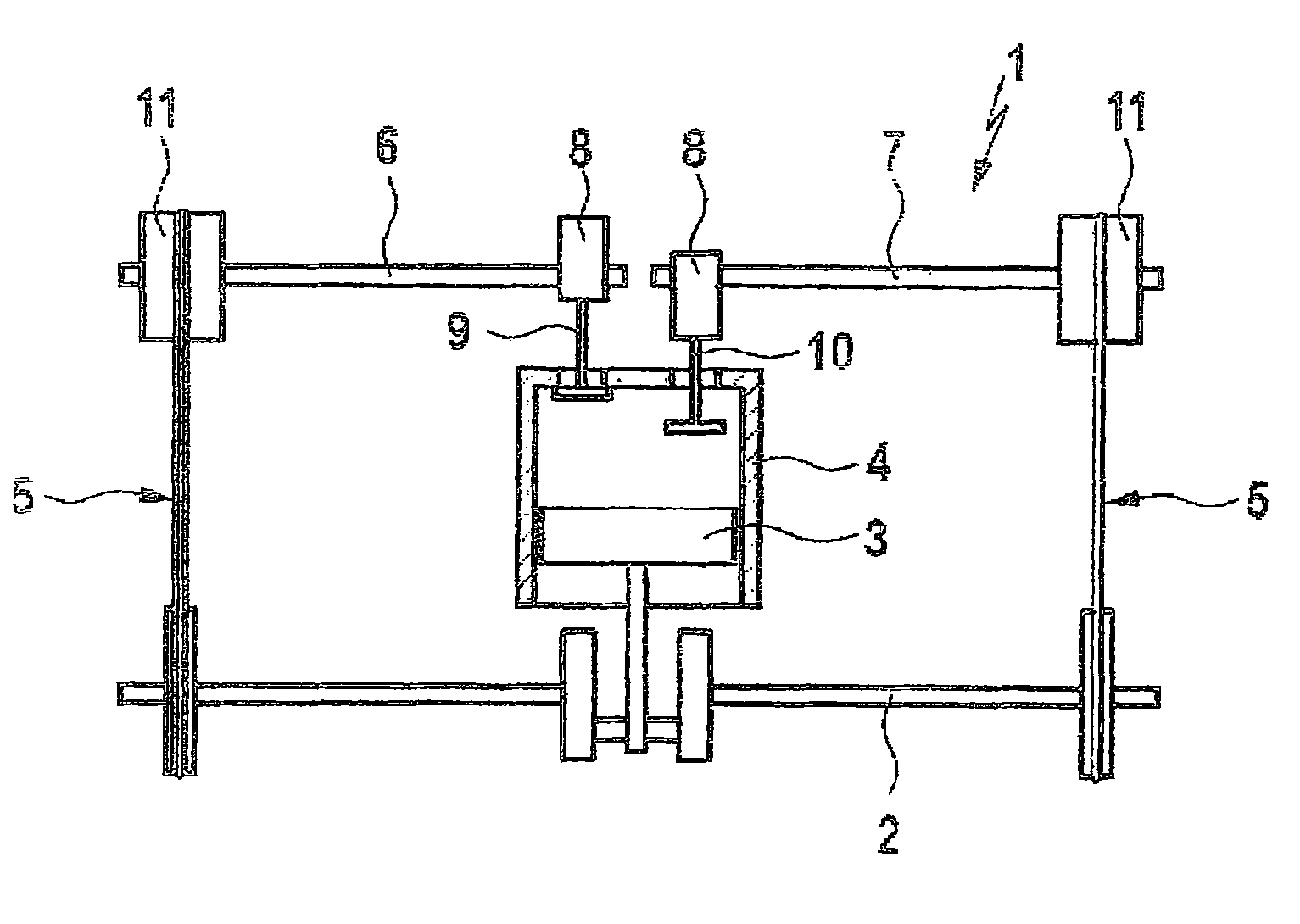

[0028] exist figure 1Shown is an internal combustion engine 1 , wherein a piston 3 on a crankshaft 2 is represented in a cylinder 4 . In the embodiment shown, the crankshaft 2 is connected to the intake camshaft 6 or the exhaust camshaft 7 via a traction mechanism transmission 5 in each case, wherein a first and a second device 11 can be responsible for the crankshaft 2 and the camshaft 6, 7 relative rotation between. The cams 8 of the camshafts 6 , 7 actuate one or more intake gas exchange valves 9 or one or more exhaust gas exchange valves 10 . It can likewise be provided that only one camshaft 6 , 7 is equipped with the device 11 or that only one camshaft 6 , 7 is provided with the device 11 .

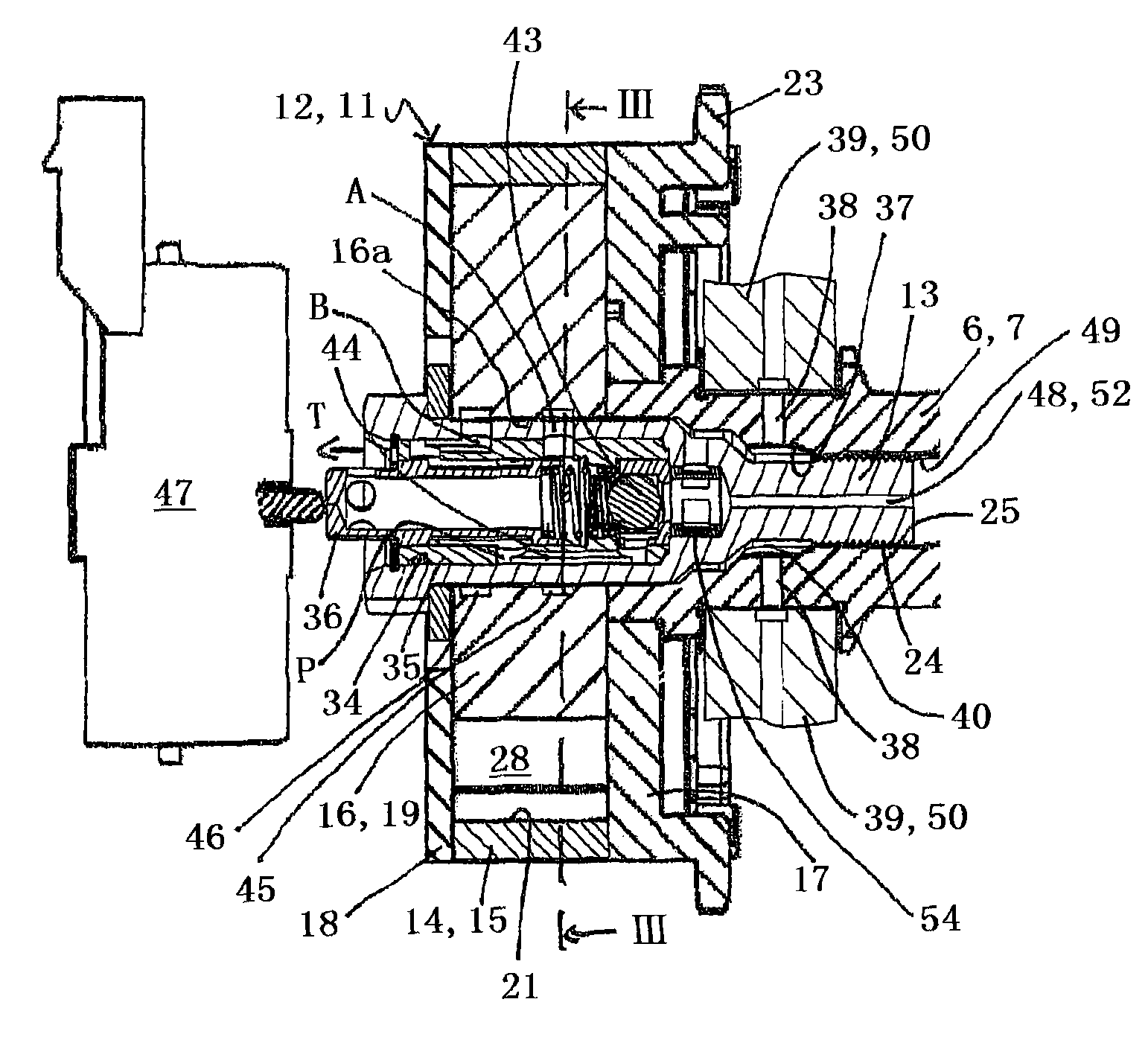

[0029] figure 2 and image 3 A first embodiment of the device 11 according to the invention is shown in longitudinal section and cross section. The device 11 has a phase adjustment device 12 , camshafts 6 , 7 and a pressure medium distributor 13 .

[0030] The phase adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com