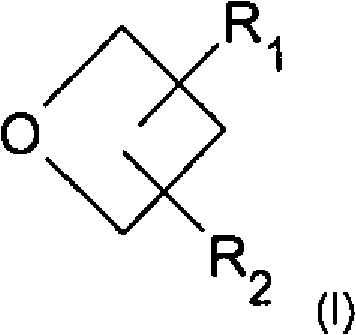

Tyre and crosslinkable elastomeric composition comprising an oxetane derivative and an amino acid

A cross-linked elastomer and oxetane technology, which is applied in special tires, tire parts, tire treads/tread patterns, etc., can solve problems such as poor affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0167] Preparation of Elastomeric Compositions 1-4

[0168] Elastomeric compositions 1-4 given in Table 1 were prepared as follows (the amounts of the individual components are given in phr).

[0169] All components except sulfur and accelerator (CBS) were mixed together in an internal mixer (model Pomini PL 1.6) for about 5 minutes (first step). As soon as the temperature reached 145±5°C, the elastomeric composition was removed. Sulfur and accelerator (CBS) are then added and mixing is carried out in an internal mixer (type Thermo Haake Rheomix 3000p) at a maximum temperature of 100° C. for about 5 minutes (second stage).

[0170] Table 1

[0171]

[0172] ( * ):Compare

[0173] (^): The present invention

[0174] NR: STR20P93 natural rubber (Thaiteck Rubber, Thailand);

[0175] SBR1: Styrene / 1,3-butadiene copolymer prepared by emulsion, the styrene content is 23.5% by weight ( 1500 - Polimeri Europa);

[0176] SBR2: Emulsion-prepared (37.5 parts TDAE oil) sty...

Embodiment 2

[0195] Preparation of Elastomeric Compositions 5-10

[0196] Elastomeric compositions 5-10 given in Table 3 were prepared as follows (the amounts of the individual components are given in phr).

[0197] All components except sulfur, accelerator (CBS) and retarder (PVI) were mixed together in an internal mixer (model Pomini PL 1.6) for about 5 minutes (first step). As soon as the temperature reached 145±5°C, the elastomeric composition was removed. Sulfur, accelerator (CBS) and retarder (PVI) are then added and mixed in an internal mixer (model Thermo Haake Rheomix 3000p) at a maximum temperature of 100° C. for about 5 minutes (second step).

[0198] table 3

[0199]

[0200]

[0201] ( * ):Compare

[0202] (^): The present invention

[0203] BR: cis-1,4-polybutadiene (Europrene BR40-Enichem Elastomeri);

[0204] SBR3: Solution prepared (37.5 parts TDAE oil) styrene / 1,3-butadiene copolymer with a styrene content of 25.0% by weight (SLR 4630-Dow Plastics);

[02...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com