Functional panel

A functional and panel technology, applied in the field of functional panels, can solve problems such as staining, deterioration, and difficulty in restoring, and achieve the effects of excellent chemical resistance, excellent staining resistance, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

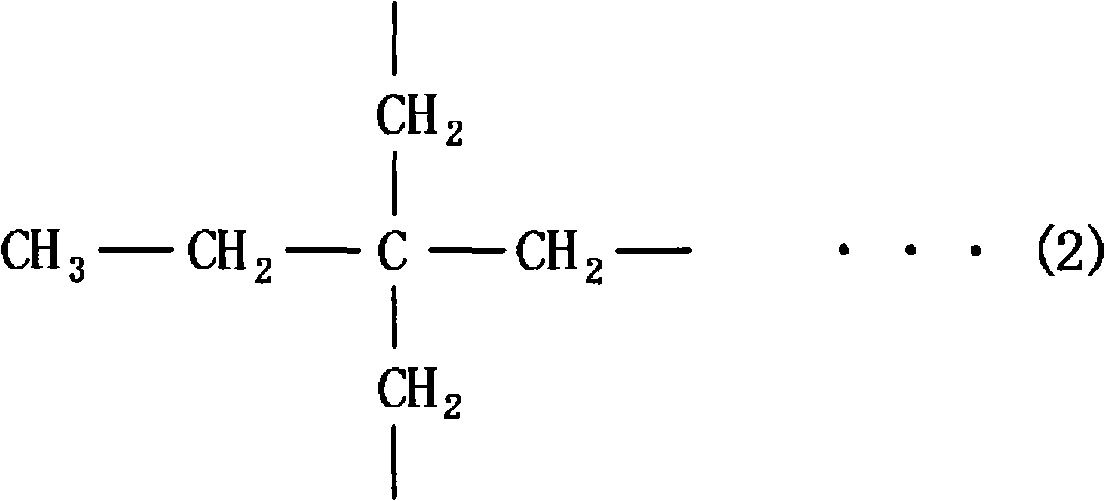

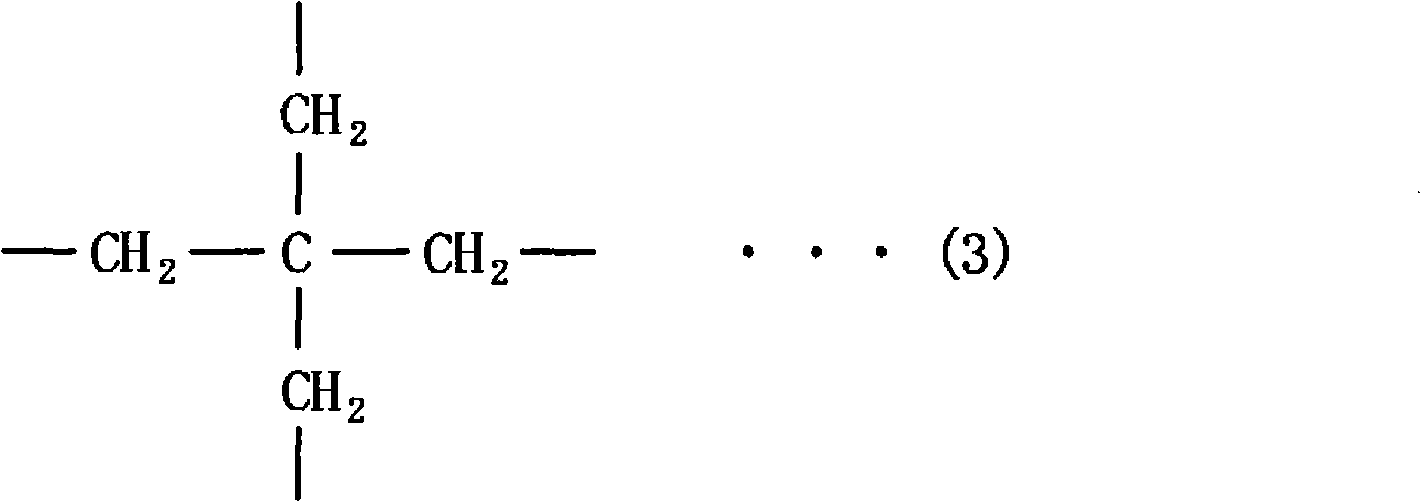

Method used

Image

Examples

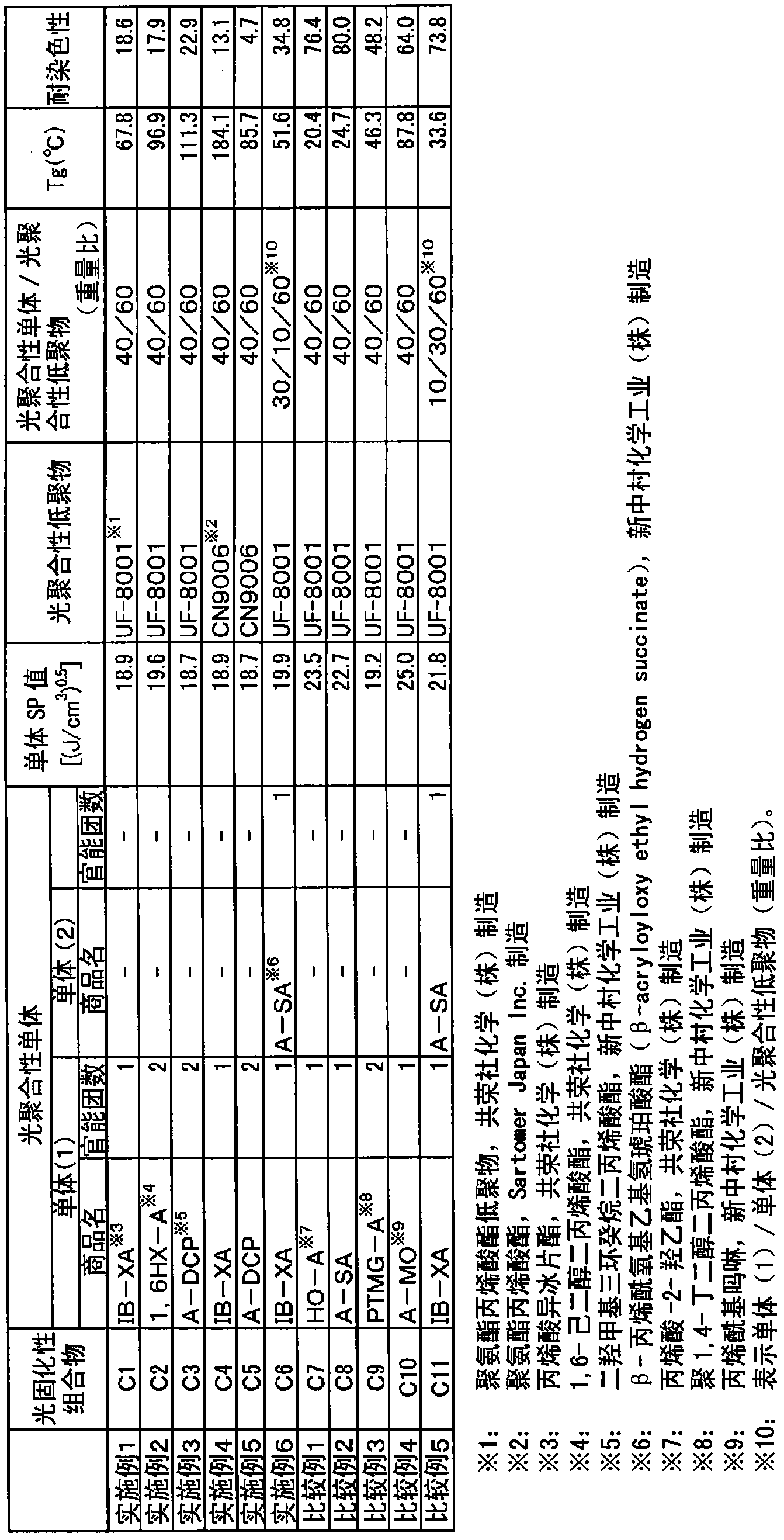

Embodiment 1

[0090] The photocurable resin composition C1 prepared above was coated on the upper surface of a substrate made of FRP (DIC Matt (registered trademark) 2415, manufactured by DIC Kako Inc.) to a thickness of 20 μm. Next, UV irradiation (1000mW / cm 2 , 4000mJ / cm 2 ) to cure the photocurable resin composition C1 to obtain a functional panel.

Embodiment 2~6

[0092] A functional panel was obtained in accordance with Example 1 except that various photocurable resin compositions C2 to C6 prepared above were used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com