High energy diode pumping solid laser realizing method

A solid-state laser and diode technology, applied in the direction of laser devices, etc., can solve the problems of complex heat dissipation structure and thermal effect processing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

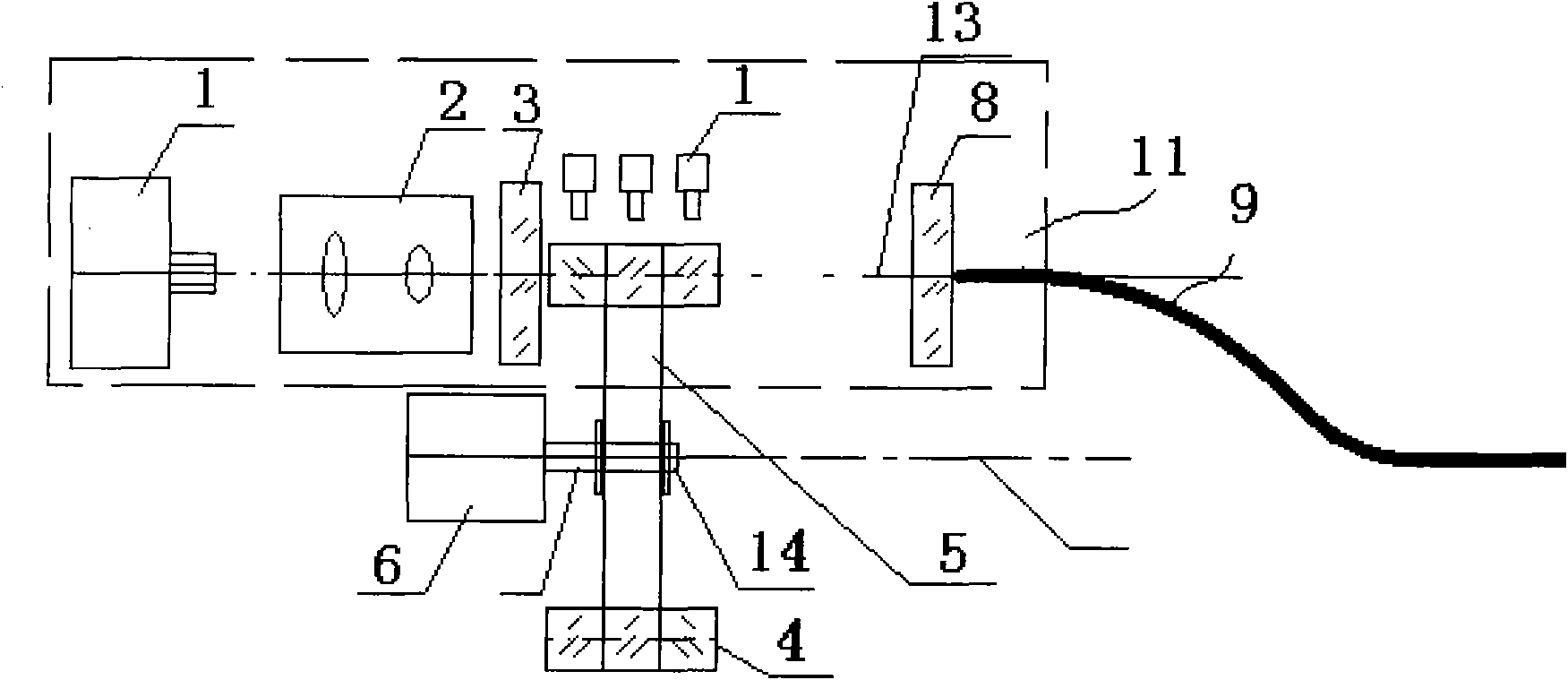

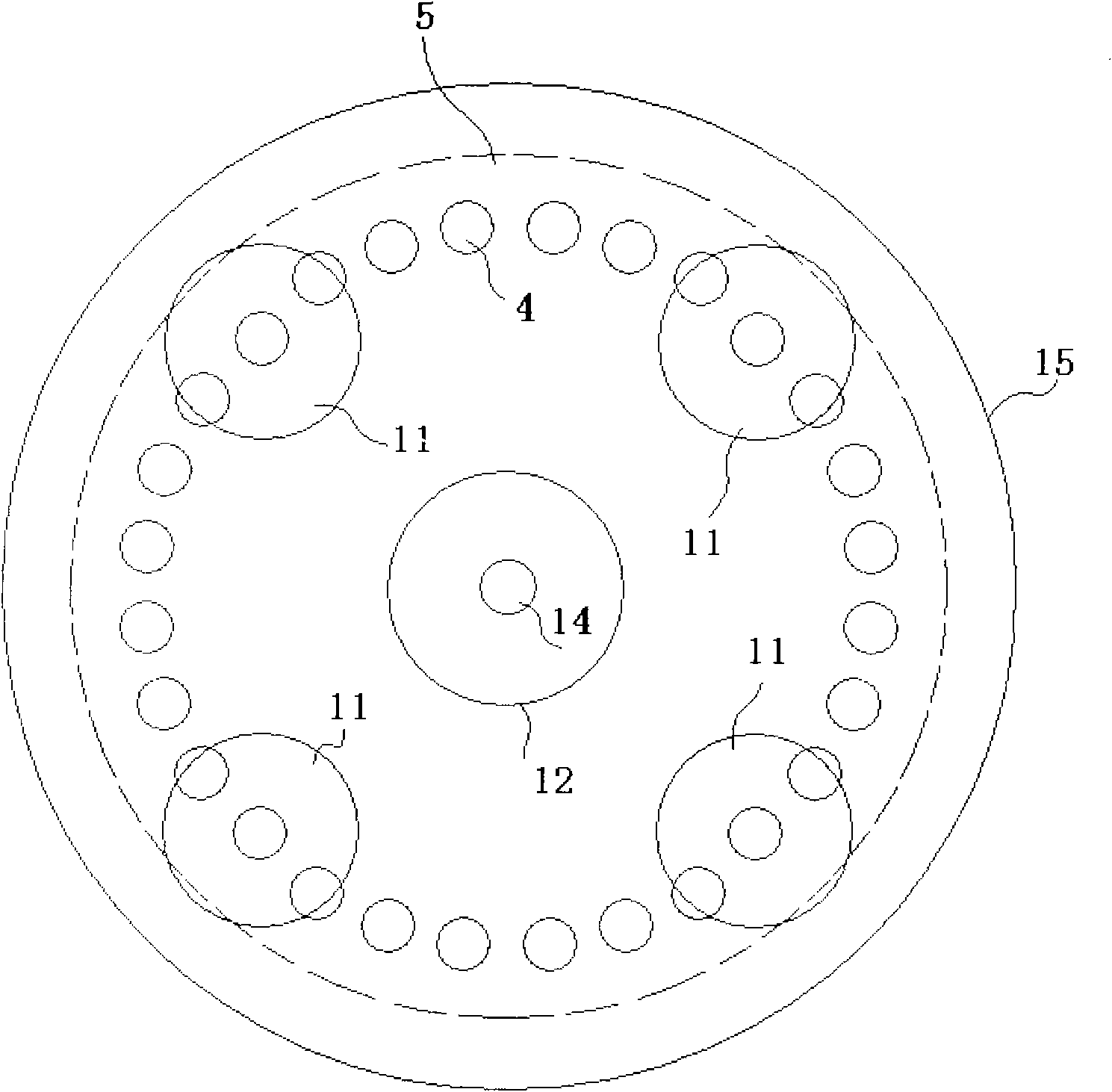

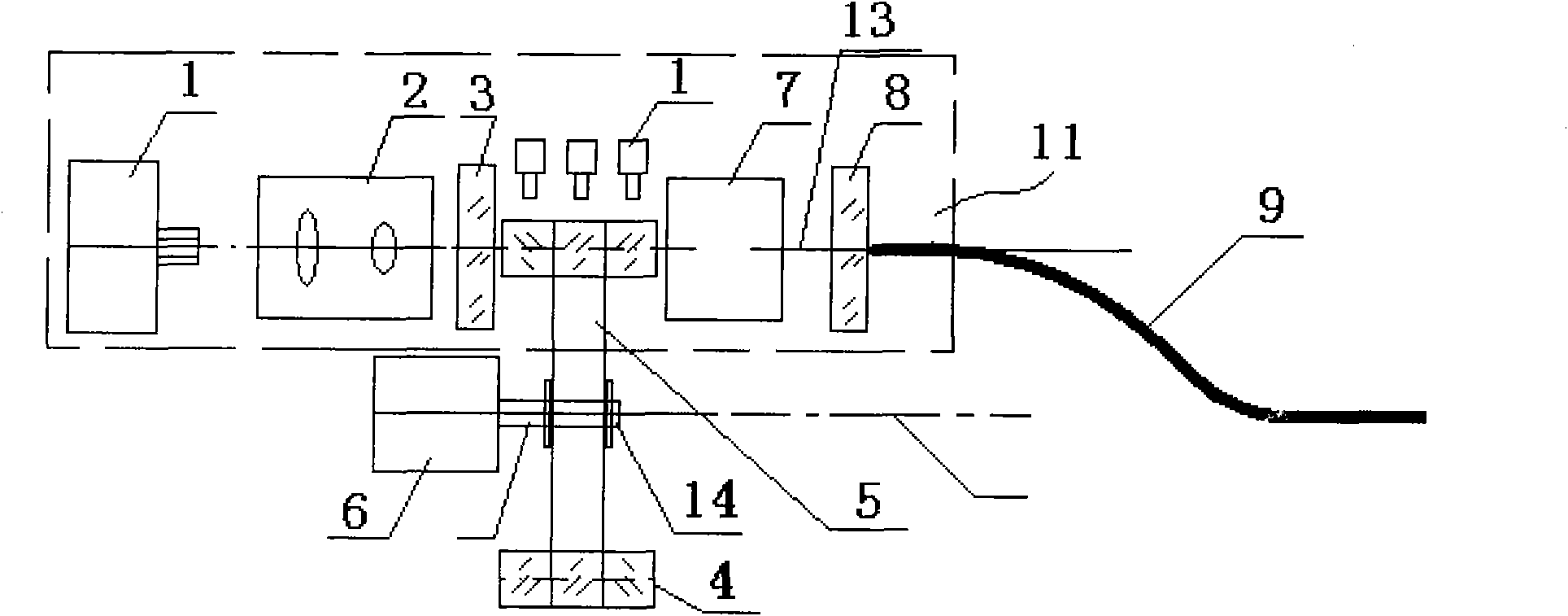

[0023] Such as figure 1 and figure 2 As shown, a diode-pumped solid-state laser 11 composed of a pump laser diode 1, a coupling system 2, a resonator mirror 3, a laser medium 4, and a laser output mirror 8, such as figure 2 As shown, multiple groups of diode-pumped solid-state lasers 11 are distributed on the housing bracket 15 with the same radius around the central axis 12, and the laser medium 4 is distributed with the same radius around the central axis of the medium disk 5 (coaxial with the central axis 12). The driving device 6 drives the medium disk 5 to rotate, so that the laser medium 4 in the medium disk 5 falls on the optical axes 13 of all laser resonator cavities on the housing support 15 . Such as figure 1 as shown, figure 1 Give a schematic diagram of a diode-pumped solid-state laser in 2, by figure 1 The working process of multiple groups of diode-pumped solid-state lasers 11 can be understood from the description. exist figure 1 In this method, pumping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com