Hydraulic system of coal mining machine

A technology for hydraulic systems and shearers, applied in the field of hydraulic systems, can solve the problems of scattered circuit components, low work efficiency, and slow optimization, so as to improve control accuracy, improve work efficiency, and prevent oil temperature from being too high or too low. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

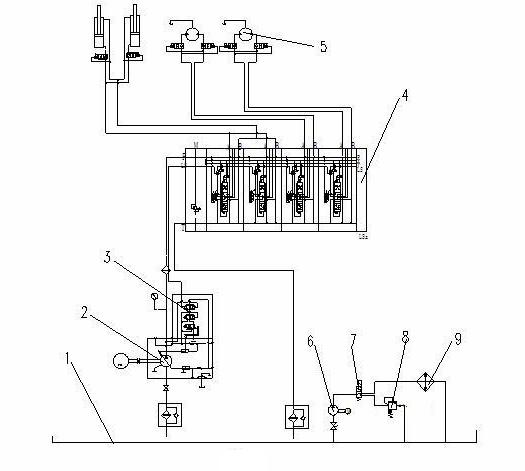

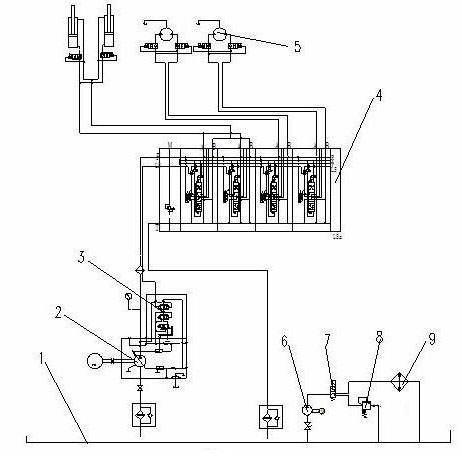

[0012] figure 1 Among them, a hydraulic system of a coal mining machine is mainly composed of an oil tank 1, a variable pump 2, a variable mechanism 3, a four-way reversing valve 4, a hydraulic actuator 5, an auxiliary gear pump 6, a three-way reversing valve 7, and an overflow valve 8 and cooler 9, characterized in that: one end of the variable pump 2 is connected to the oil tank 1 through the oil suction filter through the pipeline, and the other end is connected to the four-way reversing valve 4 and the four-way reversing valve 4 through the variable mechanism 3 The load sensing circuit is connected to the variable mechanism 3, the variable mechanism 3 of the pump is connected to the control pump 2, the working oil port of each valve of the four-way reversing valve 4 is respectively connected to the hydraulic actuator 5, and the oil in the auxiliary hydraulic circuit passes through the gear pump 6 After connecting the two-position three-way reversing valve 7, connect the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com