On-line vibration detection device and method for equipment state of hot finishing mill

A technology of equipment status and vibration detection, which is applied in the direction of length measuring devices, metal processing equipment, metal rolling, etc., can solve problems such as difficult fault location, hard to distinguish, and incomplete abnormal information, and achieve the effect of increasing authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

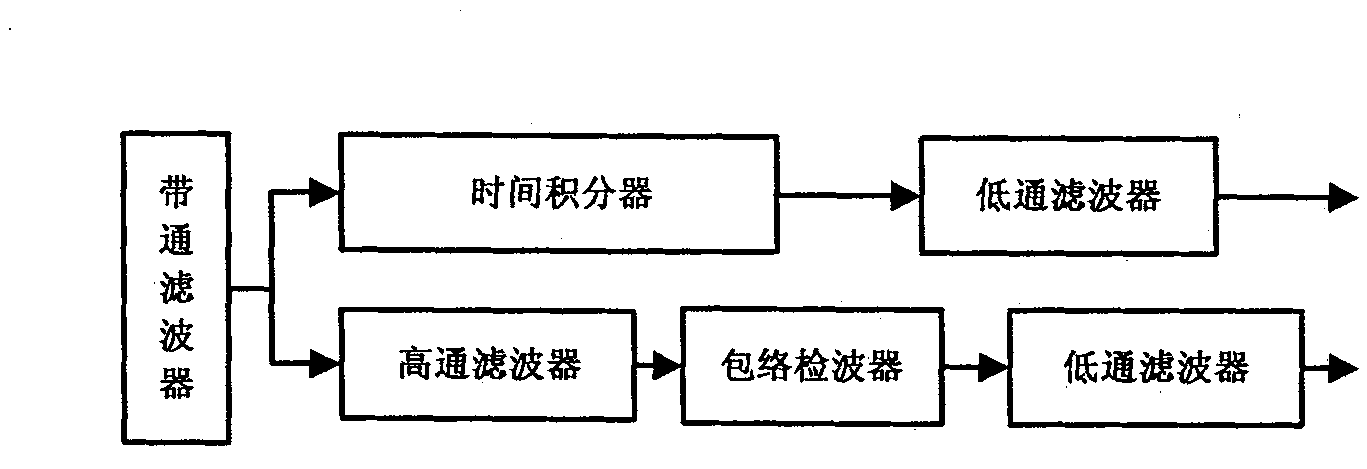

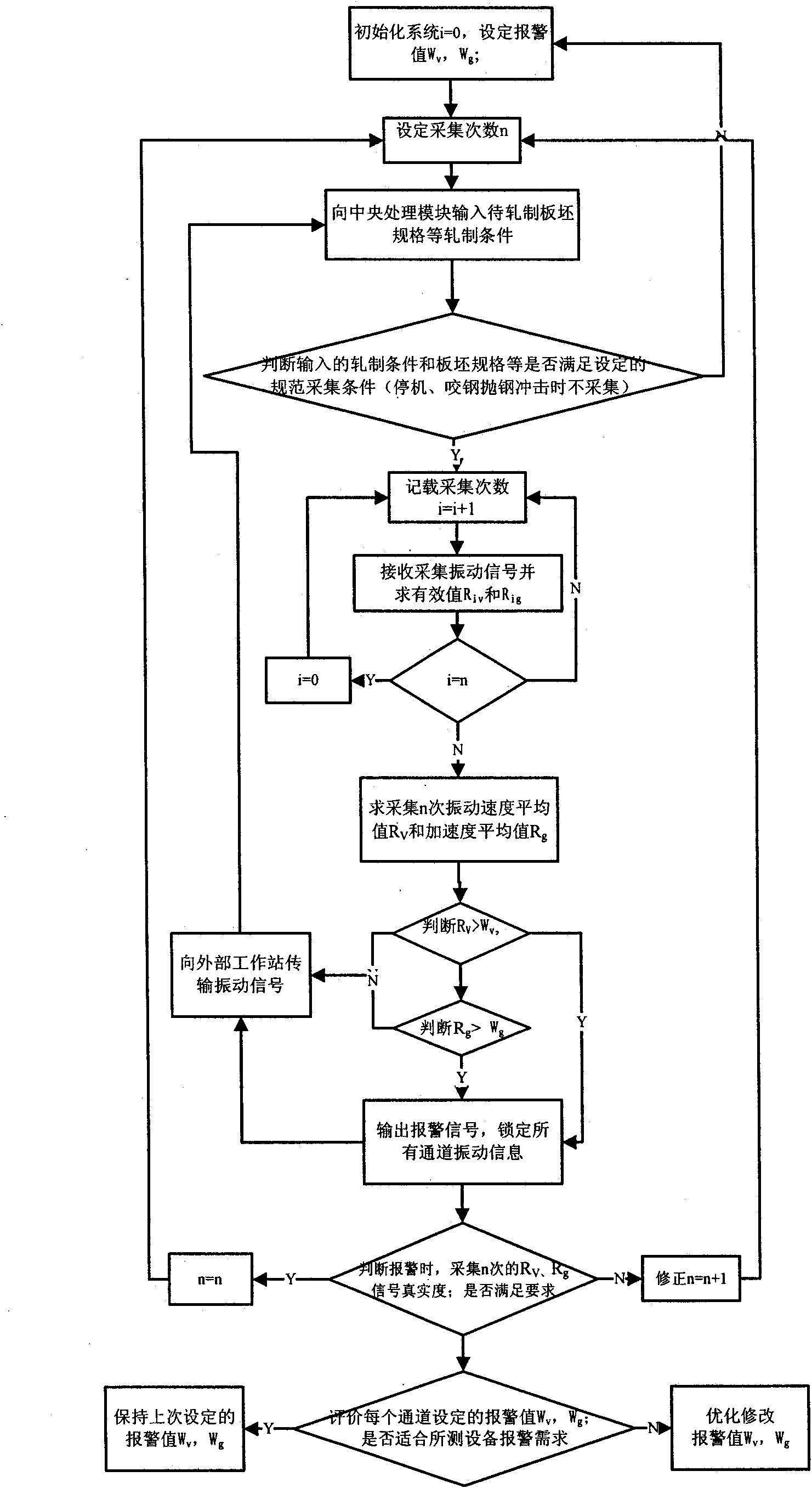

[0028] The on-line vibration detection device of the equipment state of the hot rolling finishing mill in this embodiment is as follows: figure 1 As shown, the vibration acceleration sensor is placed on the vibration measuring point of the equipment, and its signal output terminal is connected to the input terminal of the front module. front module (see figure 2 ) is a band-pass filter, the band-pass filter is connected to the corresponding input of the central processing module through the integrator and the first low-pass filter, and simultaneously through the high-pass filter, the envelope detector and the second low-pass filter end. Its function is to preprocess the electrical signal from the vibration acceleration sensor. After band-pass filtering, filtering is performed according to the pass-frequency parameters set for each channel; then it is divided into two channels, one of which is time-integrated and low-pass filtered to generate an analog vibration velocity sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com