Channel for rotary extruding-type filter

A filter and extrusion technology, which is applied to the channel field of a rotary extrusion filter to achieve the effects of improving service life, improving filtration efficiency and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

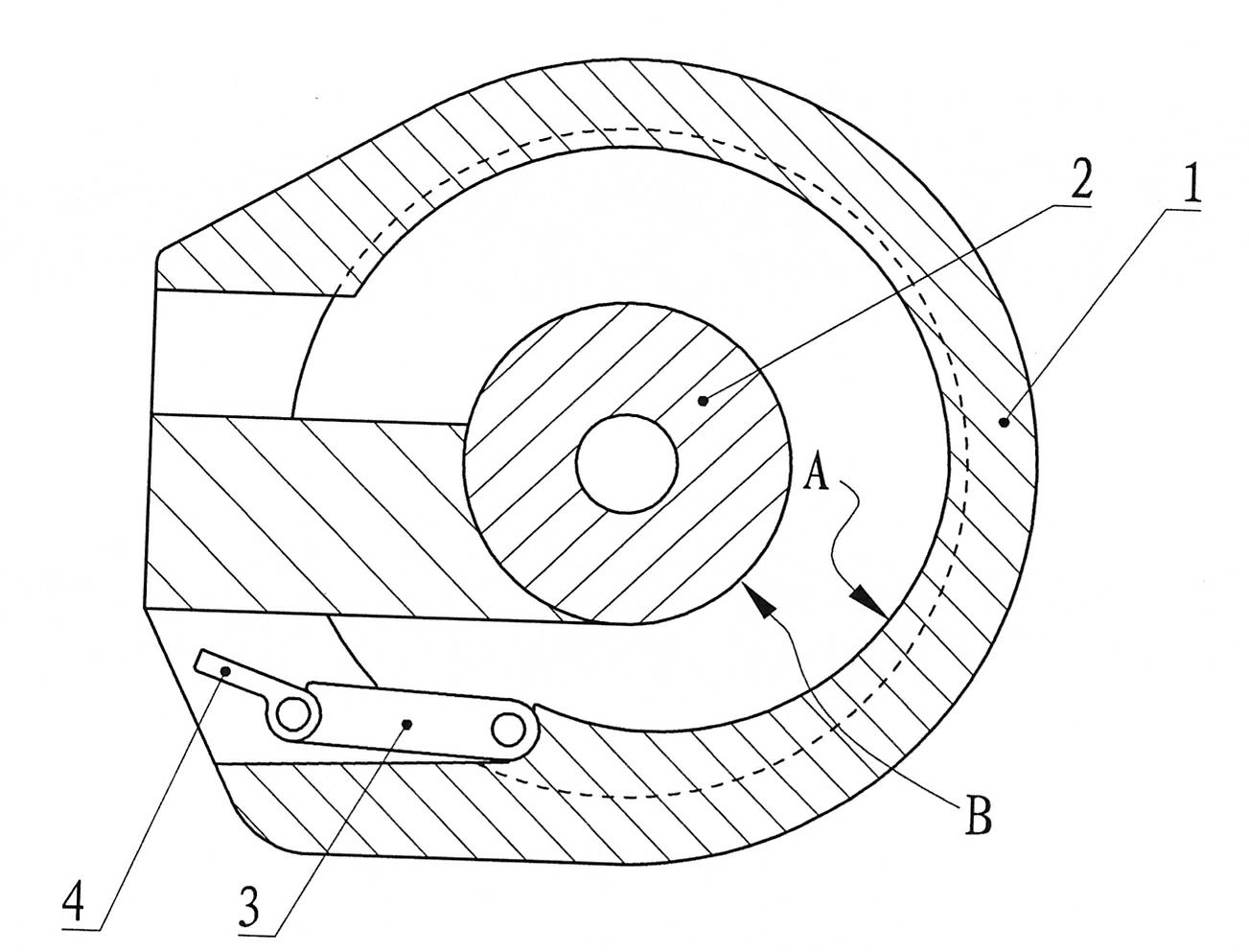

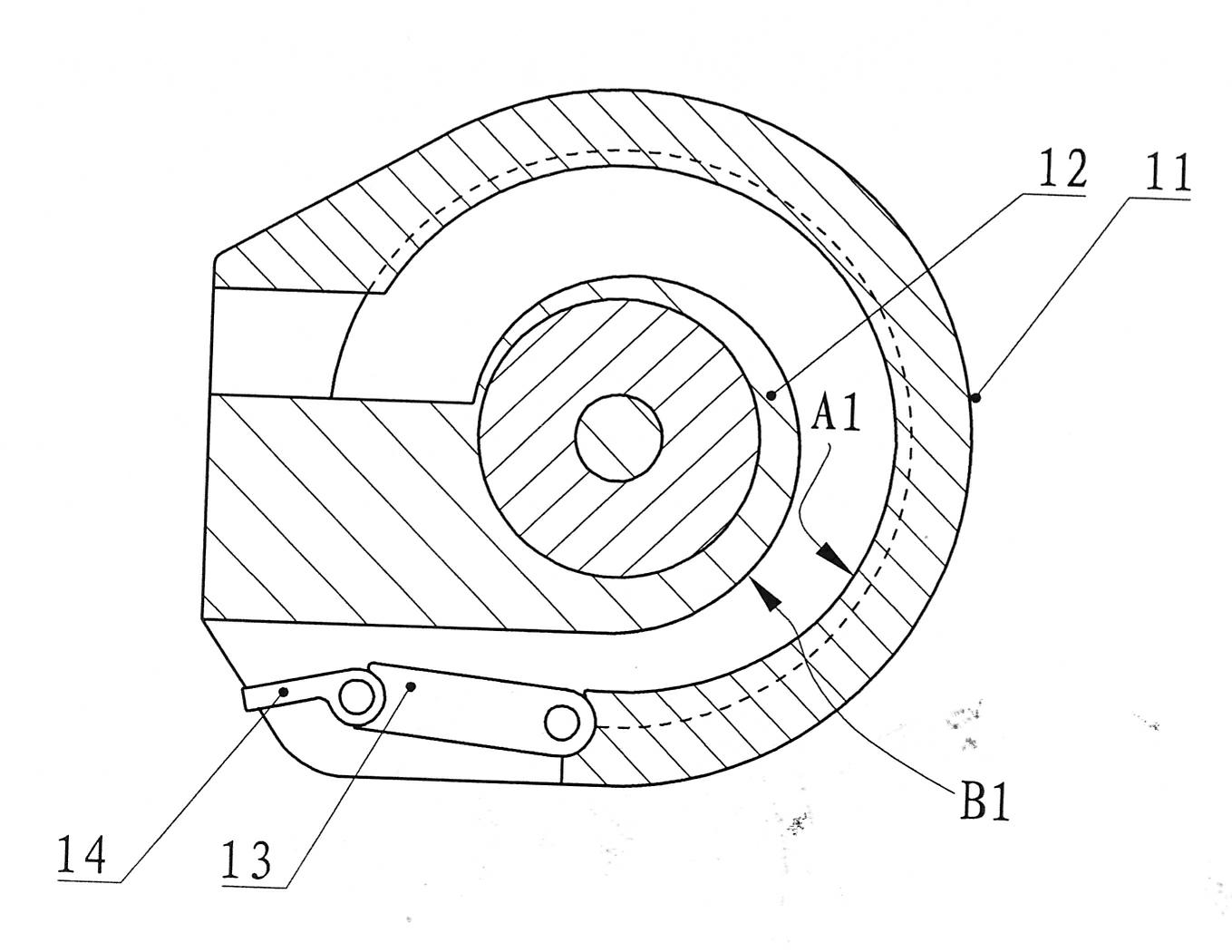

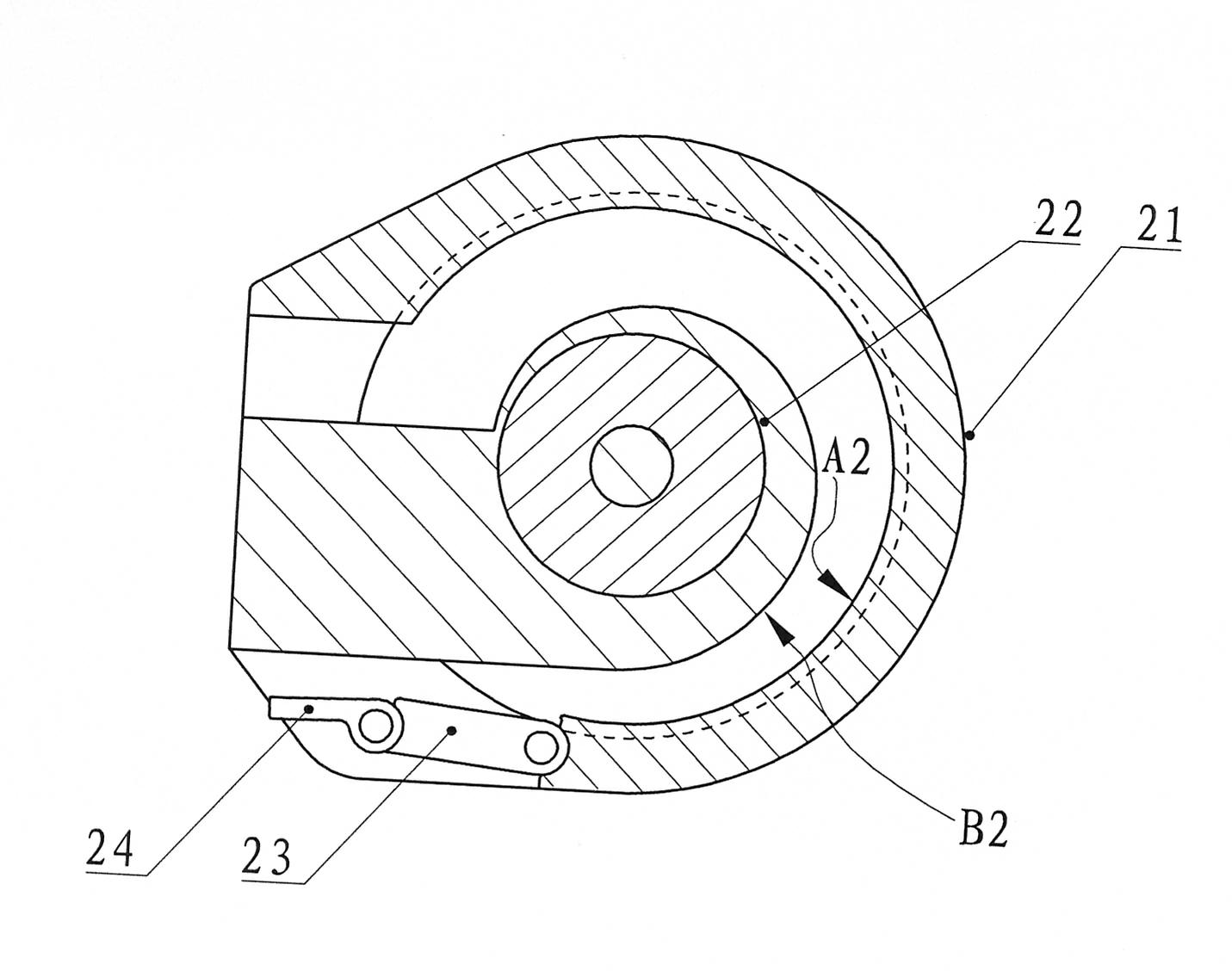

[0014] 1. There is a channel for a rotary extrusion filter, such as figure 1 As shown, it consists of a C-shaped outer isolation plate 1, an inner isolation plate 2 in the C-shape, a guide block located at the C-shaped opening and integrated with the inner isolation plate, and two filter screens installed on the rotating shaft. The inner and outer isolation plates and the guide block are clamped in the middle to form a C-shaped filter channel with the opening between the upper and lower sides of the guide block and the outer isolation plate as the inlet and outlet. The rotating shaft installed by the filter screen is located in the middle of the C-shaped channel. When working, the filter screen pushes the material from the feed port to the discharge port while separating the solid-liquid phase in the material. The filtering channel has a rectangular cross section, two side lengths forming parallel to the filter screen are two filter screens, and two side lengths forming parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com