Alloy structural steel material for brake discs of high-speed motor train unit vehicles

A technology of alloy structural steel and high-speed EMUs, which is applied in the field of alloy structural steel materials, can solve problems such as poor thermal conductivity and thermal cracking of heat capacity, and achieve good wear resistance and thermal crack resistance, stable friction coefficient, and high friction coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with embodiment:

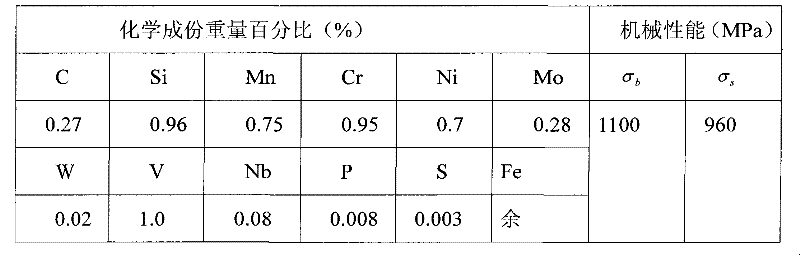

[0017] According to the composition range of the alloy structural steel material used for the brake disc of the high-speed EMU vehicle of the present invention, we determined the content of each metal element to melt the alloy steel required for the production of the brake disc according to the preparation method of the alloy structural steel material, The mechanical strength of the obtained alloy was tested, and the composition and properties of the alloy are shown in Table 1.

[0018] Table 1 Composition and properties of the alloy

[0019]

[0020] In the above embodiment, in the laboratory assessment and actual operation assessment, the measured temperature of the brake disc reaches above 600° C., and the brake disc has no cracks and obvious wear and tear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com