Measuring injection type foam proportion mixer

A proportional mixing device and proportional mixer technology, which is applied in the direction of mixers, fluid mixers, transportation and packaging, etc., can solve the problems of large pressure loss of solvents, pressure loss, and inability to obtain accurate foam ratios. Simple, set and change simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, innovative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

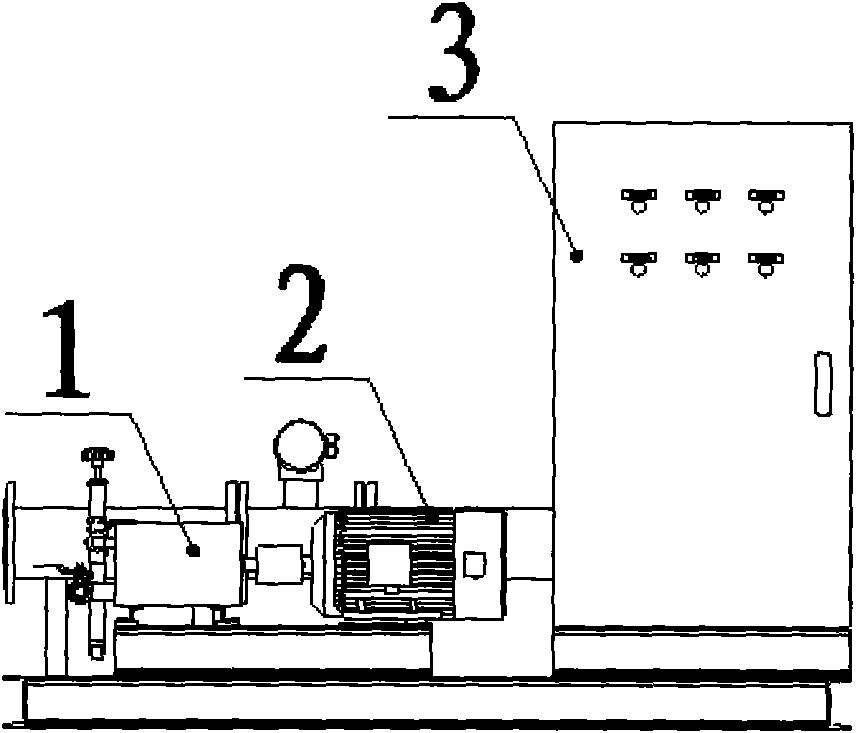

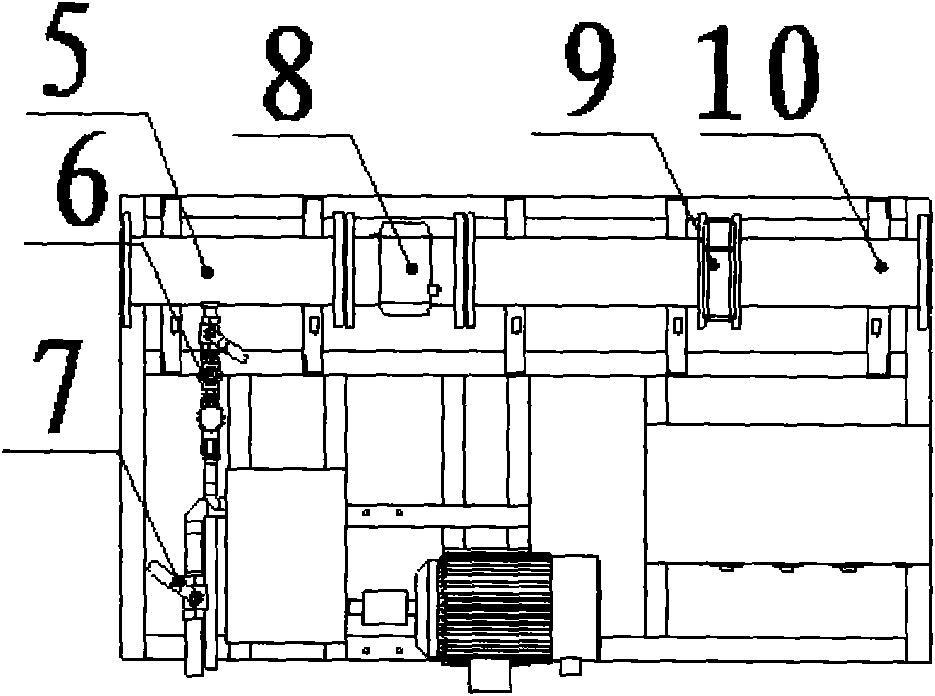

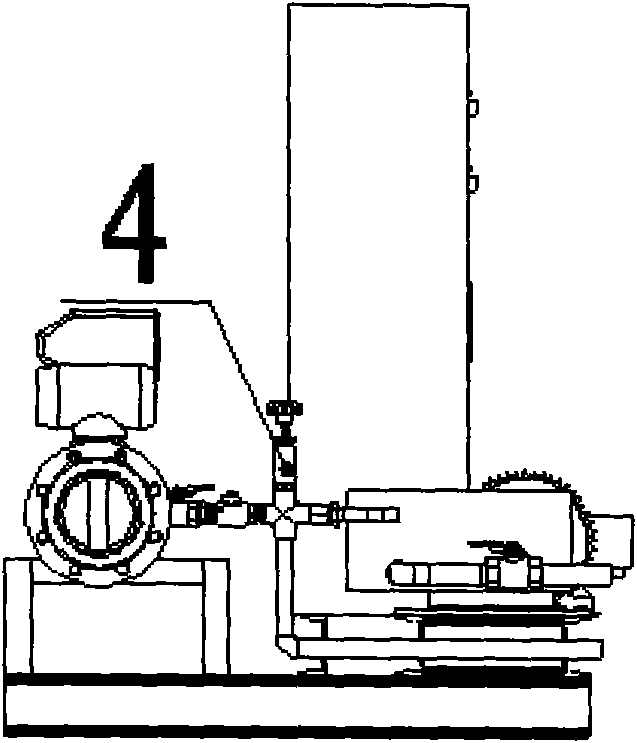

[0032] Such as Figure 1a , Figure 1b with Figure 1c As shown, the metering injection type foam proportional mixing device of the present invention includes a solvent delivery pipeline, which includes one or more solvent pipelines 10 for delivering solvent (usually water), in which a butterfly valve 9, flow rate Meter 8 and foam proportional mixer 5; Wherein, said foam proportional mixer 5 is a tee pipe or a Venturi tube, which can be arranged before flow meter 8 or after flow meter 8; said butterfly valve 9 is used to control water flow opening Stop; the flowmeter 8 is an electromagnetic flowmeter, and its interior is a straight-through pipeline, which has a negligible impact on the pressure of the water flow. An automatic range switching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com