Vacuum circuit breaker with electromotive force compensation circuit

A technology of vacuum circuit breaker and compensation circuit, applied in the direction of high-voltage air circuit breaker, circuit, electric switch, etc., can solve the problems of unfavorable electric compensation force directly acting on vacuum interrupter, loosening, increasing the depth of circuit breaker, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable the public to fully understand the technical essence and beneficial effects of the present invention, the applicant will describe in detail the specific implementation of the present invention below in conjunction with the accompanying drawings, but the applicant's description of the embodiments is not a limitation to the technical solution. Changes in the form of the inventive concept rather than in substance should be regarded as the protection scope of the present invention.

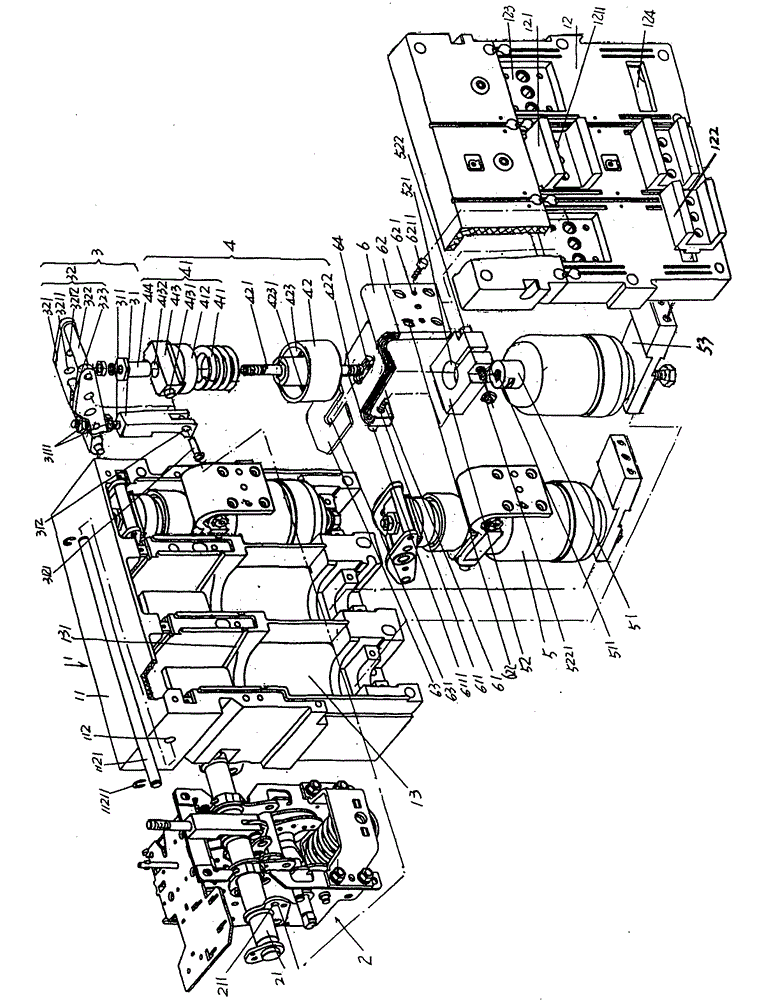

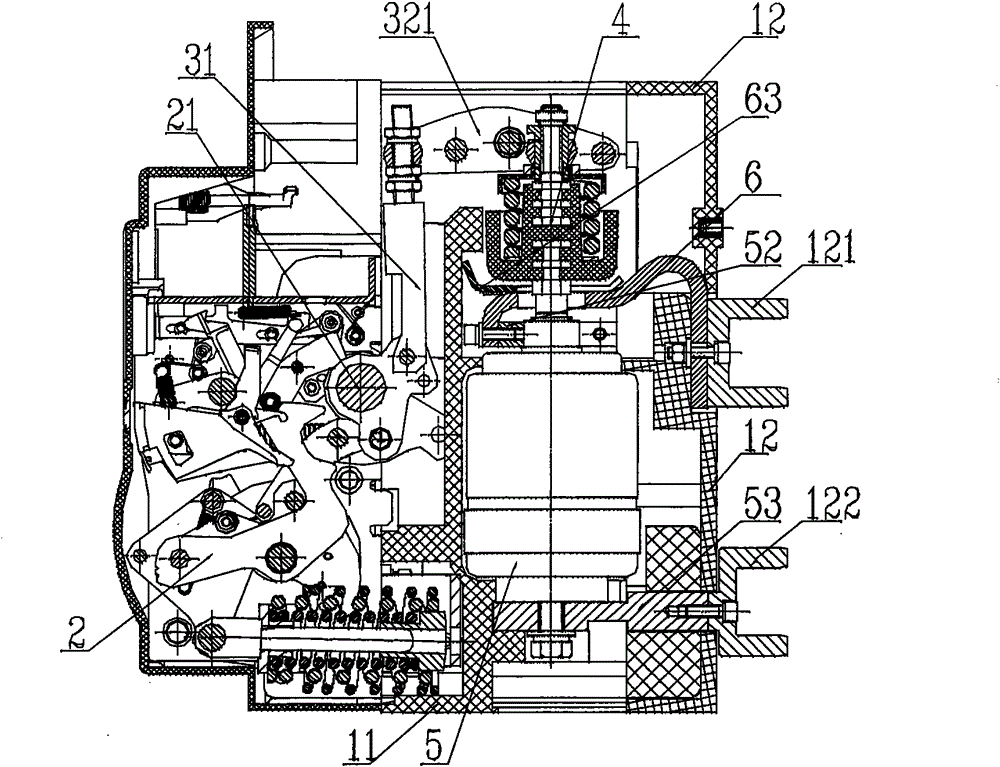

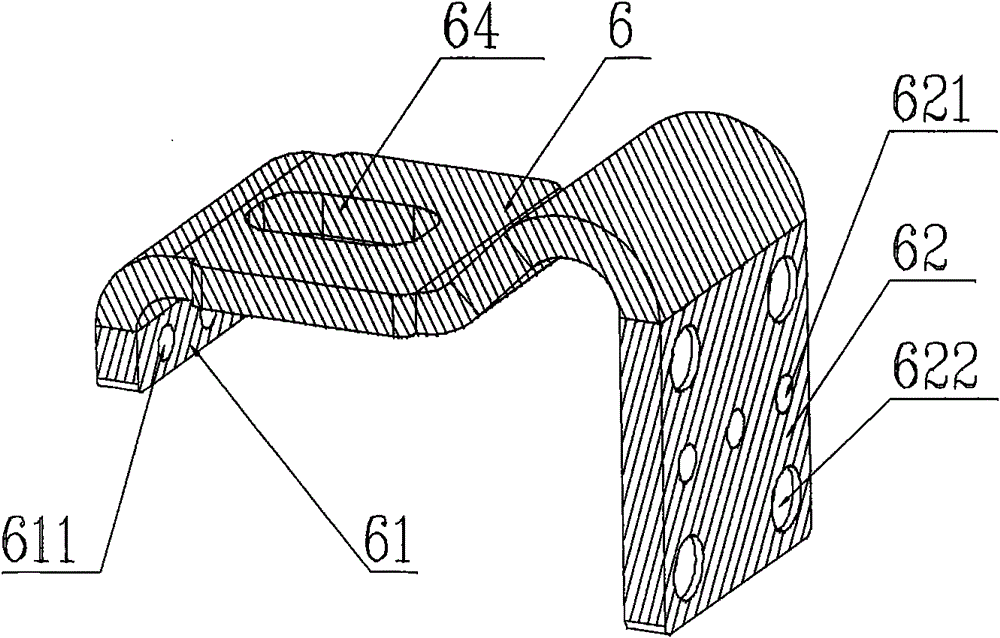

[0029] See figure 1, a vacuum circuit breaker with an electrodynamic compensation circuit of the present invention includes a housing 1, an operating mechanism 2, a set of vacuum interrupters 5, an upper busbar 121 and a lower busbar 122, and the housing 1 includes a The base 11, a base plate 12 and a group of vacuum interrupter cavities 13 whose number is equal to the number of the vacuum interrupter 5, the base plate 12 is matched with the base 11, that is, both are covered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com