Three-stage temperature control method for azimuth-holding instrument

A technology of orientation and temperature control area, applied in temperature control, instrument, non-electric variable control, etc., can solve the problems of affecting the working accuracy of the inertial system, affecting the geometric size of the platform support, and unable to accurately guarantee the working temperature of the gyro, so as to improve the accuracy , The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

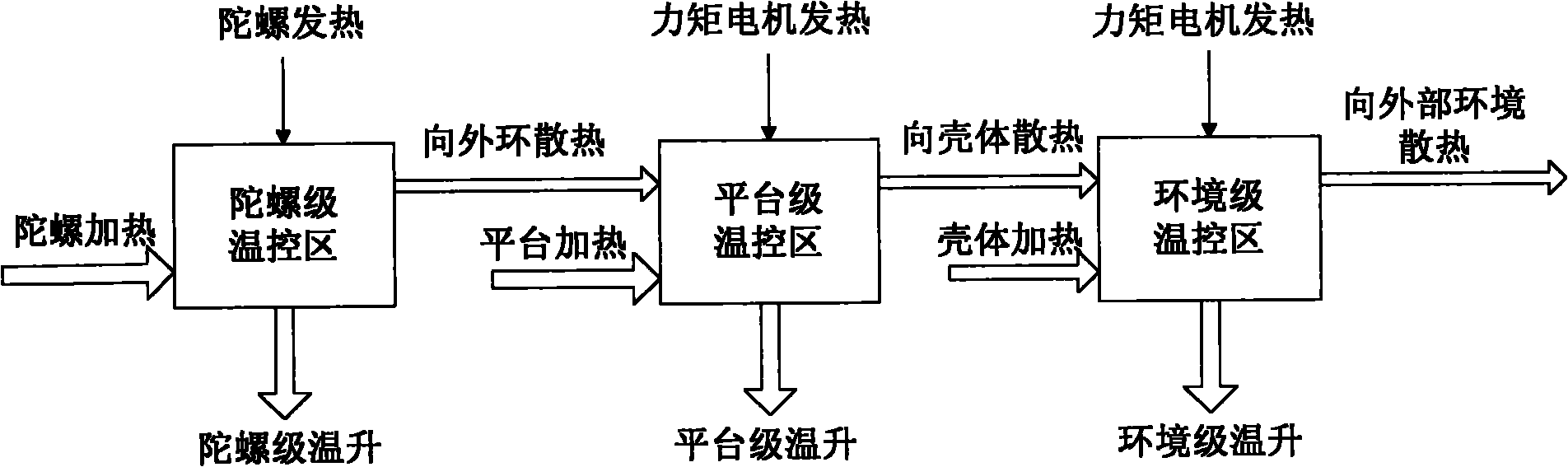

[0079] The azimuth holding instrument composed of gyroscope, platform inner ring assembly, platform outer ring assembly, and housing, when the ambient temperature is -30°C, the azimuth holding instrument is divided into three temperature zones for temperature control:

[0080] The first-level temperature zone, which is the environment-level temperature control zone, is the part other than the platform inner ring components, platform outer ring components and gyroscope, and is used to resist the harsh conditions of the outside world. The temperature rise of the environment-level temperature control zone is controlled by the shell. Heating, torque motor heating, and platform-level temperature control zone heat dissipation to the shell are jointly balanced and controlled; the temperature and error of the environment-level temperature control zone are -5±0.2°C;

[0081] The second-level temperature zone, which is a platform-level temperature control zone, is composed of platform in...

Embodiment 2

[0086] The azimuth holding instrument composed of gyroscope, platform inner ring assembly, platform outer ring assembly, and housing, when the ambient temperature is 15°C, the azimuth holding instrument is divided into three temperature zones for temperature control:

[0087] The first-level temperature zone, which is the environment-level temperature control zone, is the part other than the platform inner ring components, platform outer ring components and gyroscope, and is used to resist the harsh conditions of the outside world. The temperature rise of the environment-level temperature control zone is controlled by the shell. Heating, torque motor heating, and platform-level temperature control zone heat dissipation to the shell are jointly balanced and controlled; the temperature and error of the environment-level temperature control zone are 30±0.2°C;

[0088] The second-level temperature zone, which is a platform-level temperature control zone, is composed of platform inn...

Embodiment 3

[0093] The azimuth holding instrument composed of gyroscope, platform inner ring assembly, platform outer ring assembly, and housing, when the ambient temperature is 45°C, the azimuth holding instrument is divided into three temperature zones for temperature control:

[0094] The first-level temperature zone, which is the environment-level temperature control zone, is the part other than the platform inner ring components, platform outer ring components and gyroscope, and is used to resist the harsh conditions of the outside world. The temperature rise of the environment-level temperature control zone is controlled by the shell. Heating, torque motor heating and heat dissipation from the platform-level temperature control zone to the shell are jointly balanced and controlled; the temperature and error of the environment-level temperature control zone are 55±0.2°C;

[0095] The second-level temperature zone, which is a platform-level temperature control zone, is composed of plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com