Microwave drying PID (proportion integration differentiation) control method based on increment improved BP (back propagation) neural network

A BP neural network, microwave drying technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of slow convergence, local minimum point, unable to converge, etc., to achieve strong adaptive ability and general The effect of improving the ability to improve the convergence speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] Embodiment: based on incremental improvement BP neural network dynamic real-time tuning method for microwave drying process PID controller parameters, divide following three steps:

[0016] (1) Data collection: Select the data of the actual production process as sample data, including microwave input power, microwave action time, material speed, material relative dehydration rate and material temperature, and normalize the sample data to between 0 and 1;

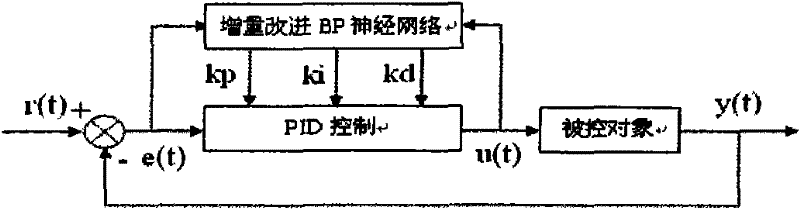

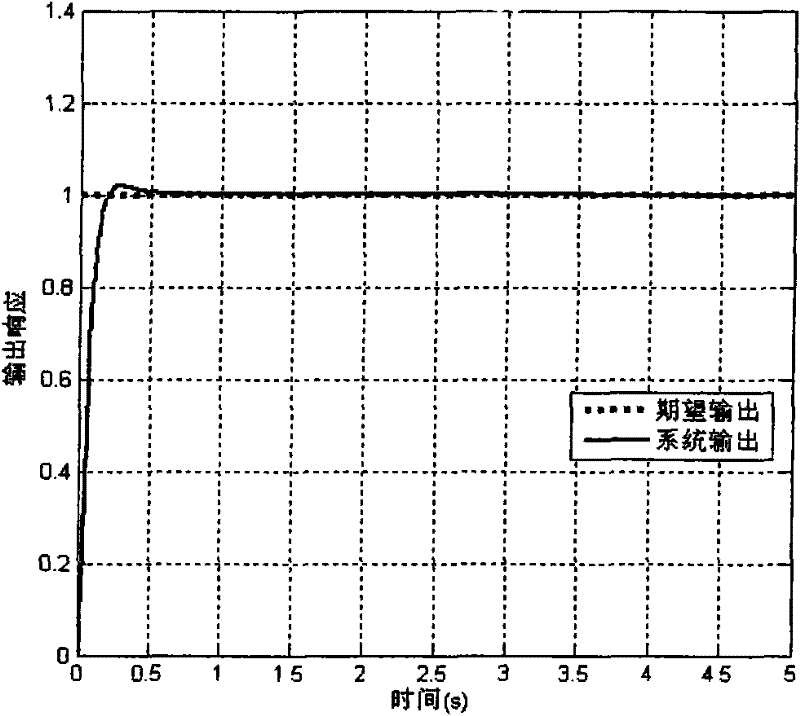

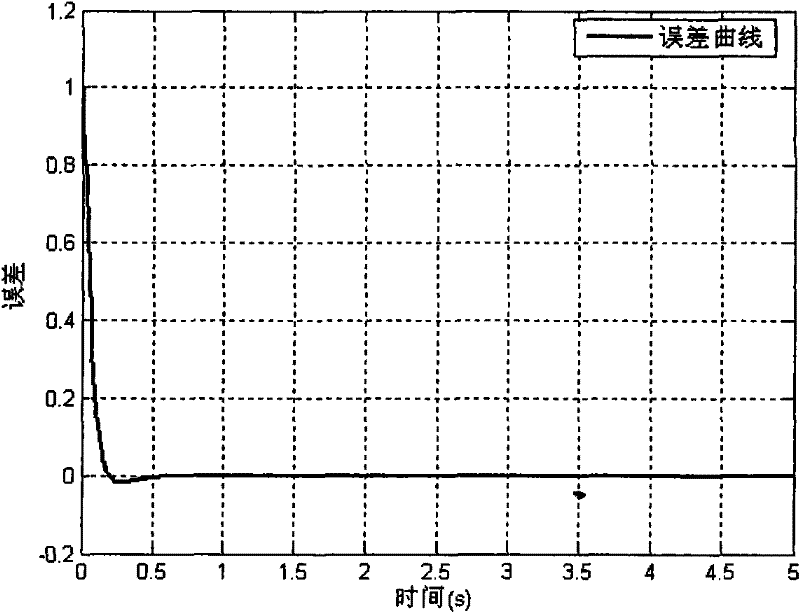

[0017] (2) Establish an incrementally improved BP neural network PID control model, and train and test the network: the controller consists of two parts: one is a known PID controller, which is used to directly perform closed-loop control on the controlled object, and realizes Three parameters K p 、K i 、K d Online tuning; the second is to incrementally improve the BP neural network. According to the operating state of the system, through the self-learning of the neural network and the adjustment of the weighting coe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com