Multi-medium combined heat exchanger test bed

A heat exchanger test, combined technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of equipment and energy waste, unable to solve the comprehensive test of the radiator cooling system, unable to meet the development trend of heat exchangers, etc., to achieve the degree of automation High, improve design strength and design level, and facilitate the effect of progress status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

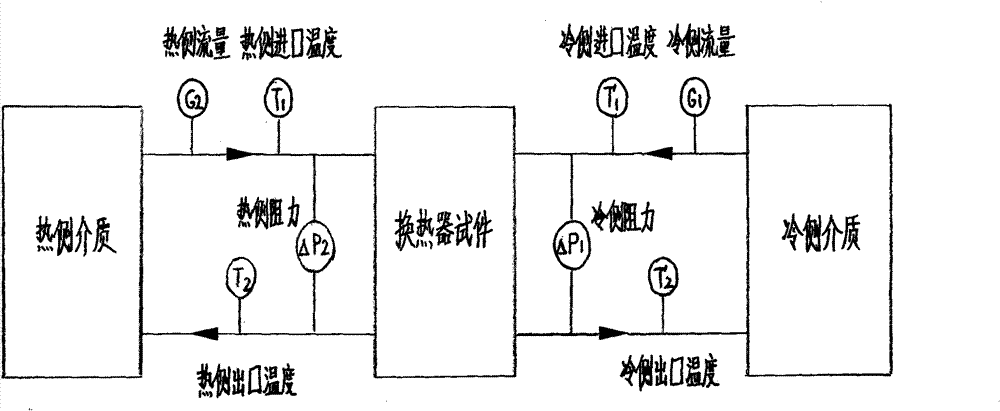

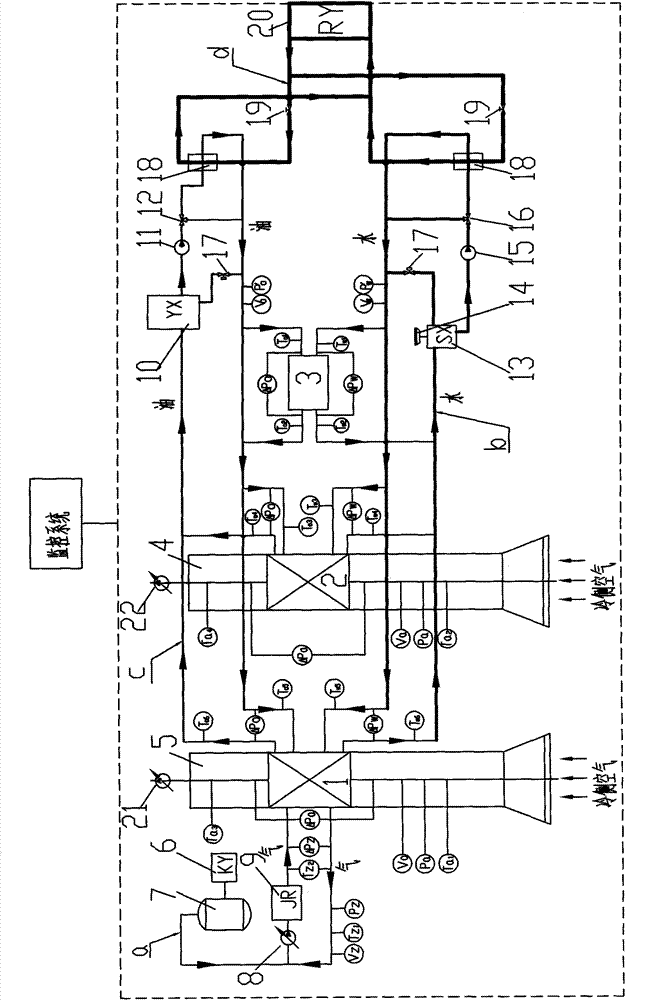

Embodiment 1

[0031] When conducting the thermal performance test of the air-to-air cooler, the working part is the intercooler test bench part of the multi-media combined heat exchanger test bench, which consists of the intercooler test bench wind tunnel 5, air compressor 6, air storage tank 7, Circulating fan 8, heater 9, intercooler test bench wind tunnel fan 21, measuring instrument A and air pipeline a. First, set the test parameters through the monitoring system: the pressure, temperature, and flow of air on the hot side and the temperature and flow of air on the cold side. After the test started, according to the instructions of the monitoring system, the operating equipment of the intercooler test bench first started to work at a low speed in a steady state, so that the air entering the test piece I, the cold and hot sides flowed and circulated in the air pipeline a. The air compressor 6 fills the outside air into the air storage tank 7 and reaches the set pressure, the circulating ...

Embodiment 2

[0033] When testing water radiators, oil radiators, water-oil composite radiators and oil-water coolers, the working part is the water / oil heat exchanger test bench part of the multi-media combined heat exchanger test bench. This part consists of water circulation system, oil circulation system, thermal energy supply system, water / oil test wind tunnel system. The water circuit circulation system consists of water tank 13, expansion water tank 14, water pump 15, electric water diversion valve 16, electric regulating valve 17, measuring instrument B and water pipeline b; oil circuit circulation system consists of oil tank 10, oil pump 11, electric oil diversion valve 12 , an electric control valve 17, a measuring instrument C and an oil pipeline c; the heat energy supply system is mainly composed of a spiral plate heat exchanger 18, a stop valve 19, a heating furnace 20, a measuring instrument D and a pipeline d. The test wind tunnel system consists of the water / oil heat exchang...

Embodiment 3

[0039] When performing water-to-air coolers, air / oil composite radiators, air / water composite radiators and air / oil / water composite radiators, the intercooler test bench and the water / oil heat exchanger test bench will be simultaneously Work. Through this series-parallel connection of the water / oil radiator test bench and the intercooler test bench, thermal performance tests of various types of heat exchangers can be carried out, and the hot side supply system of the three media of gas, oil and water can be realized Composite synchronous test combined radiator covers a wide range of types, meeting the testing needs of the heat exchanger industry.

[0040]During the water-air cooler test, the working parts are air heating system, air circulation system, water circulation system and heat energy supply system. The hot side air will pass through the air heating system and air circulation system of the intercooler test bench into the specimen I installed on the wind tunnel 5 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com