Lead screw thread pitch detector

A detector and lead screw technology, applied in the field of lead screw pitch detectors, can solve the problems of inaccuracy, high cost, influence on workpiece accuracy, etc., and achieve the effects of simple overall structure, low equipment cost, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

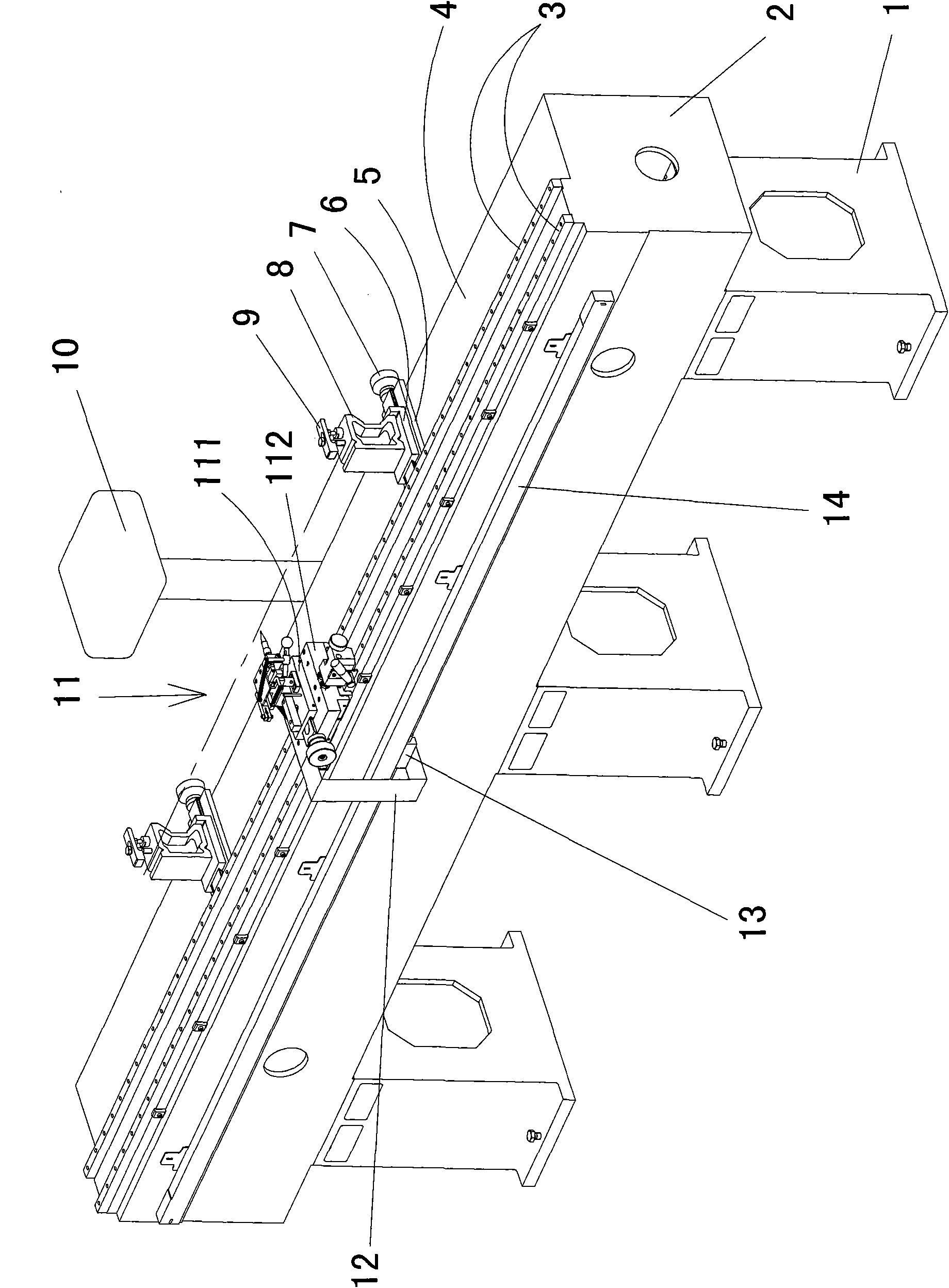

[0017] like figure 1 As shown: 1 is a bracket, and there are three brackets 1, and a base 2 is fixedly connected with a bolt above the bracket 1, and the base 2 is in the shape of a strip.

[0018] One side above the base 2 is longitudinally connected with two parallel guide rails 3 by screws, and the guide rails 3 are linear guide rails. A support surface 4 is processed on the other side of the base 2, and the longitudinal direction of the guide rail 3 is parallel to the support surface 4 and is also in a horizontal state.

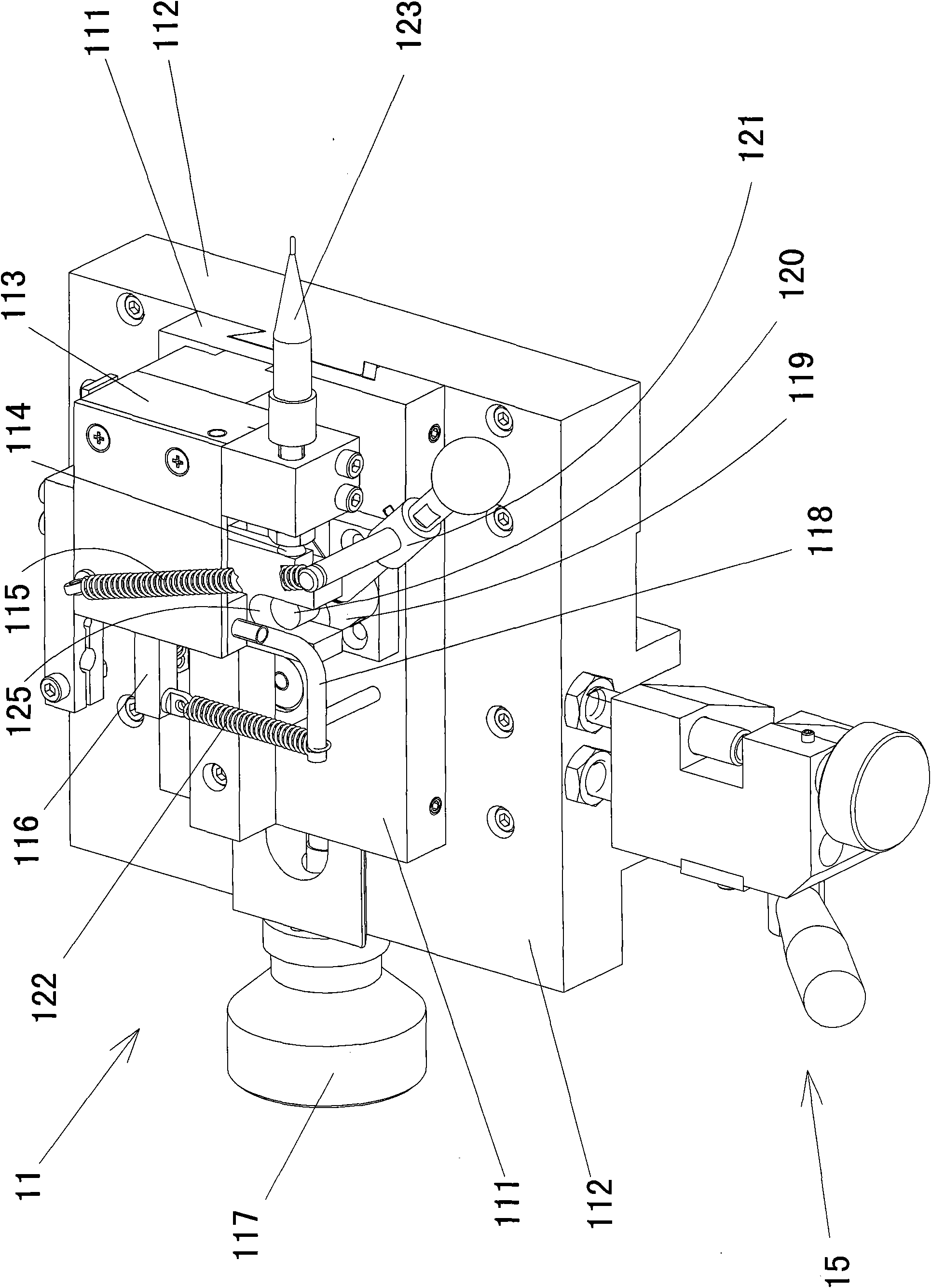

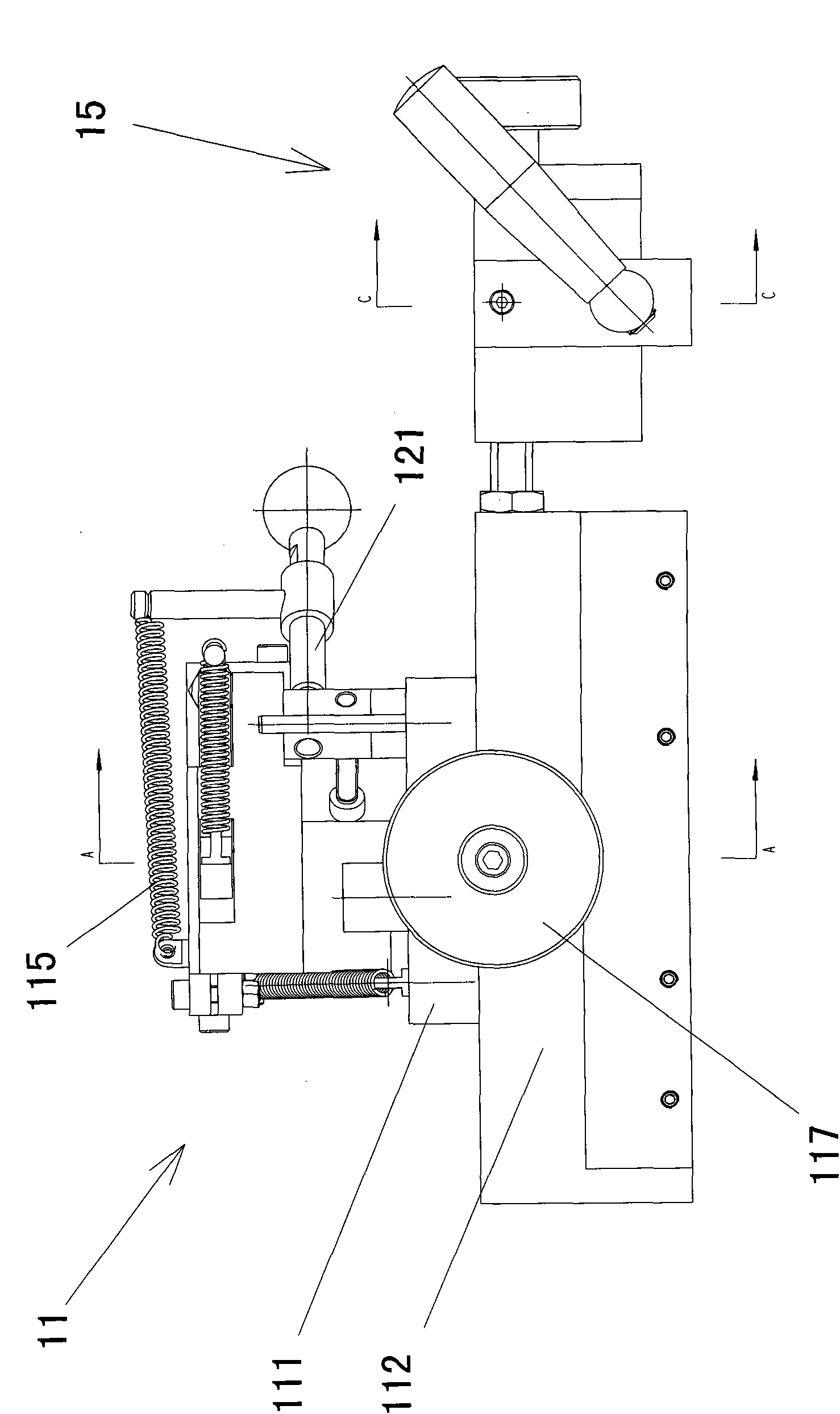

[0019] A measuring mechanism 11 is mounted on the linear guide rail 3 .

[0020] A grating scale 14 parallel to the guide rail 3 is fixedly connected to the side of the base 2 by screws, and the reading head 13 matched with the grating scale is connected to the sliding platform 112 in the measuring mechanism 11 through the connecting plate 12 . The other side of the base 2 is fixedly connected with a vertical pole, and a digital display meter 10 is scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com