Anti-explosion and ventilation control system of pneumatic control motor

A ventilation control system and air-controlled technology, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve problems such as electrical components prone to sparks, increased system design and manufacturing costs, and adverse effects on equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with specific drawings and embodiments.

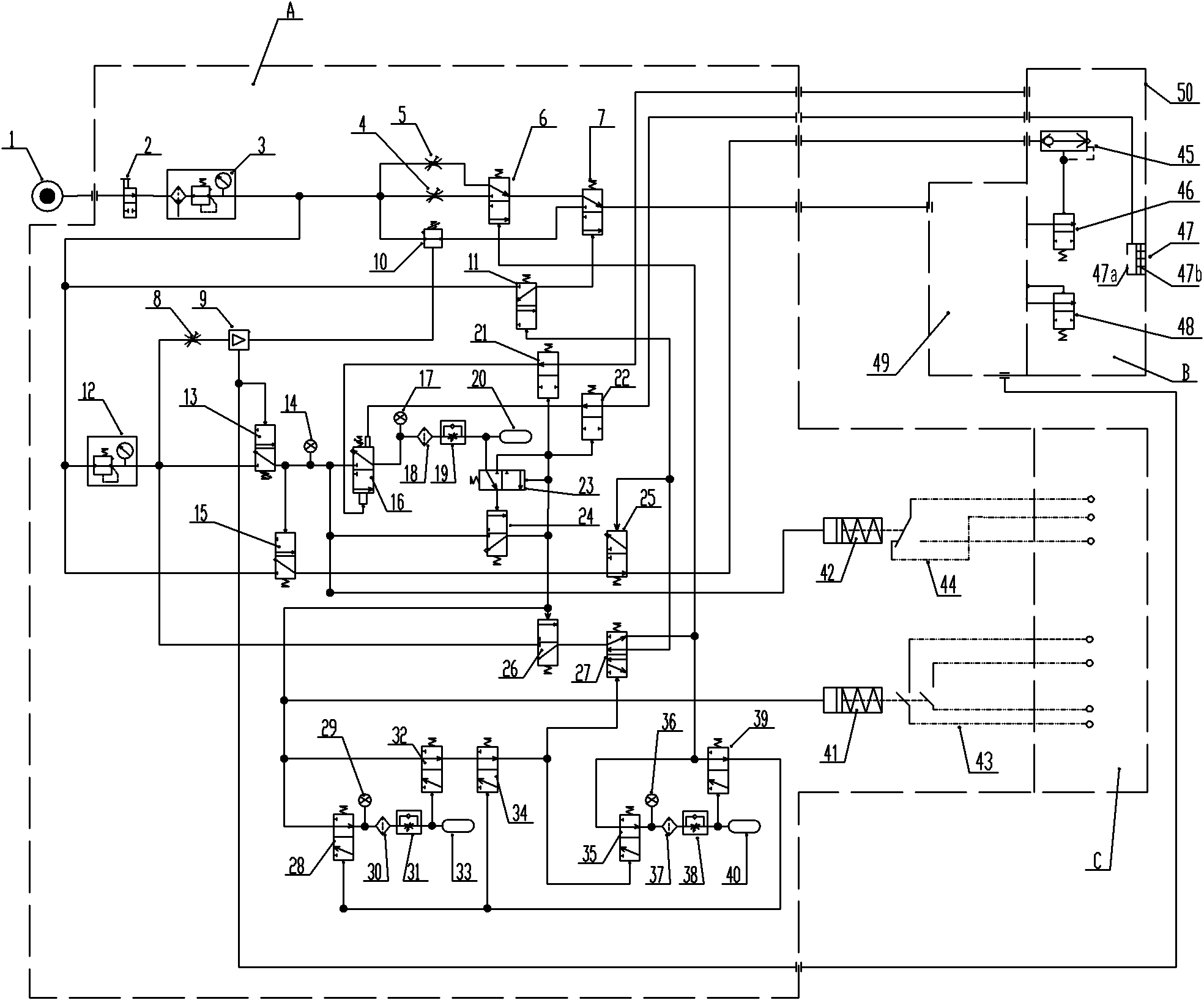

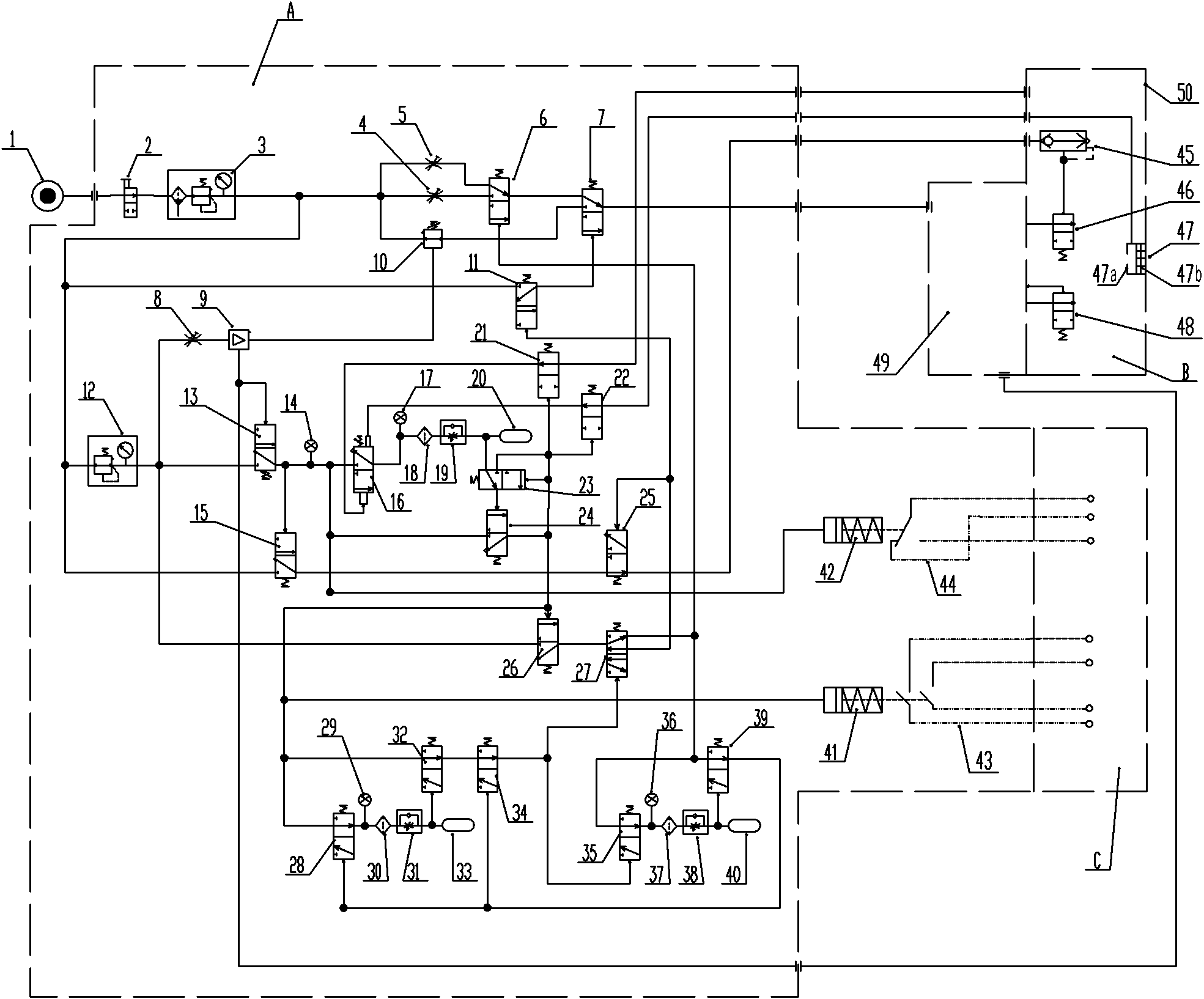

[0049] Such as figure 1 As shown, the air-controlled motor explosion-proof ventilation control system of the present invention is mainly composed of an air source 1, a pneumatic control circuit module A, a pressure relief valve module B and an explosion-proof junction box C. Among them, the gas source 1 is used to provide protective gases such as inert gas and compressed air. The pneumatic control circuit module A is connected to the air source 1, and the pneumatic control circuit module A has three working modes: a large flow purge mode, a leakage compensation mode and a small flow purge mode. The pressure relief valve module B is connected to the pneumatic control circuit module A, and the pressure relief valve module B has the function of opening or closing the ventilating outlet of the motor casing 49 . The explosion-proof junction box C is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com