Supplying device of small-flow and high-temperature gas propellant

A high-temperature gas and supply device technology, which is applied in the field of low-flow high-temperature gas propellant supply devices, achieves the effects of simple structure, easy replacement, and improved ignition reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

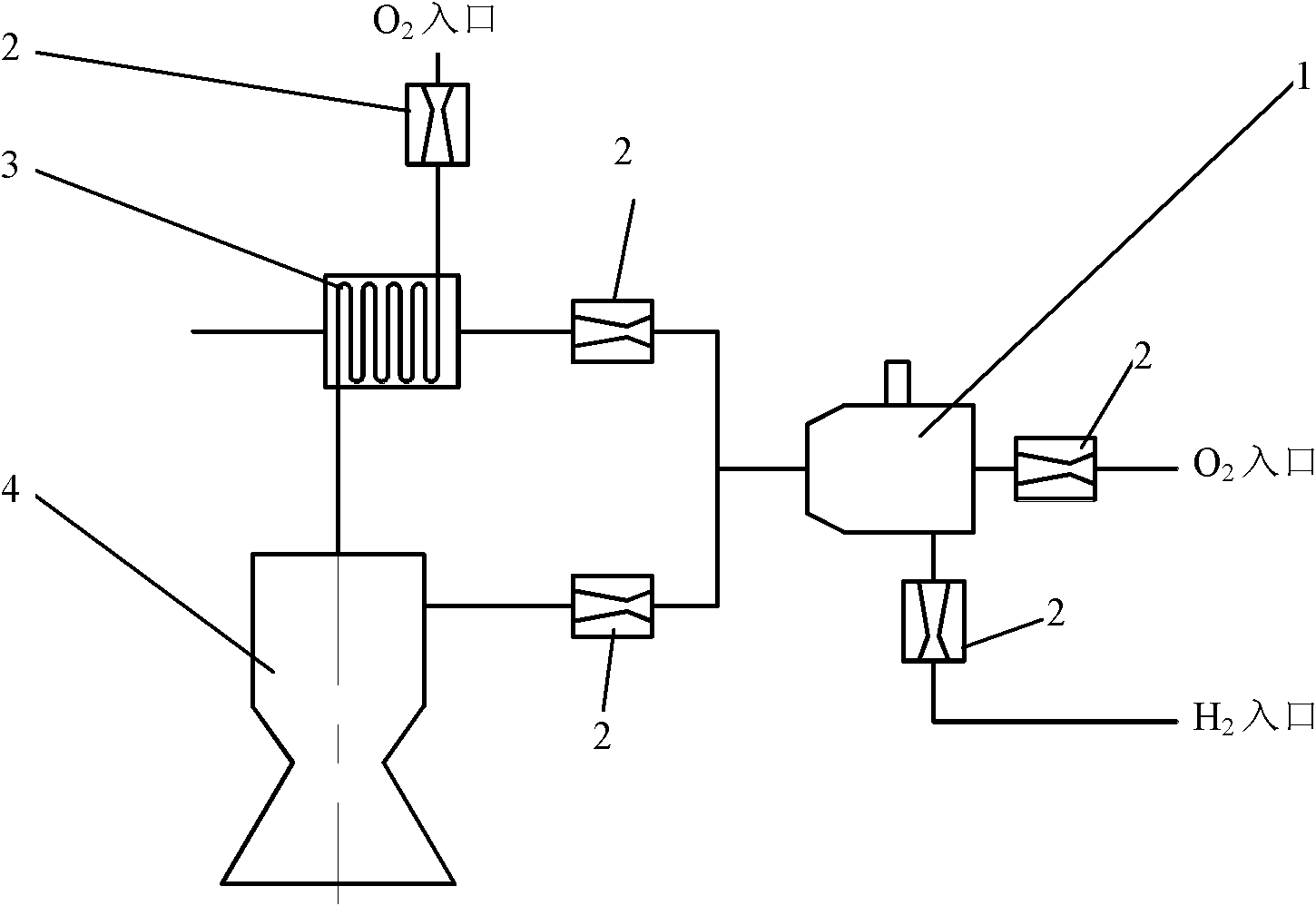

[0016] The present invention is a small-flow high-temperature gas propellant supply device, such as figure 1 As shown, it includes a small combustion chamber 1, a sonic nozzle assembly 2, a heat exchanger 3 and a gas nozzle test piece 4.

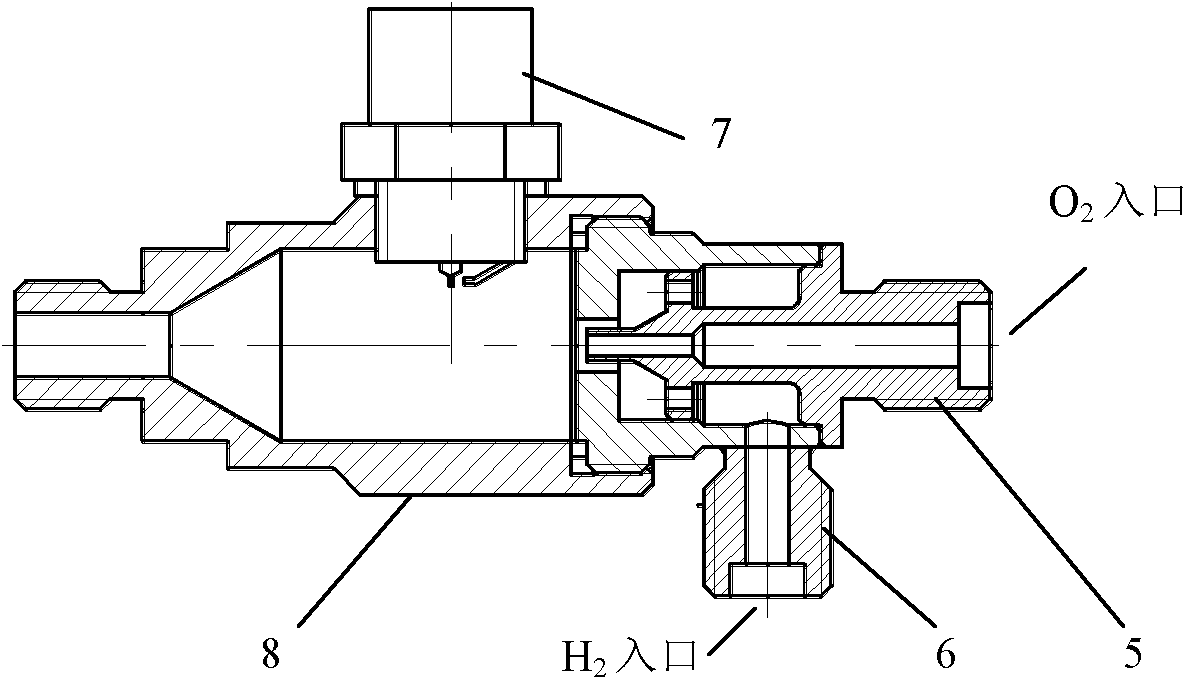

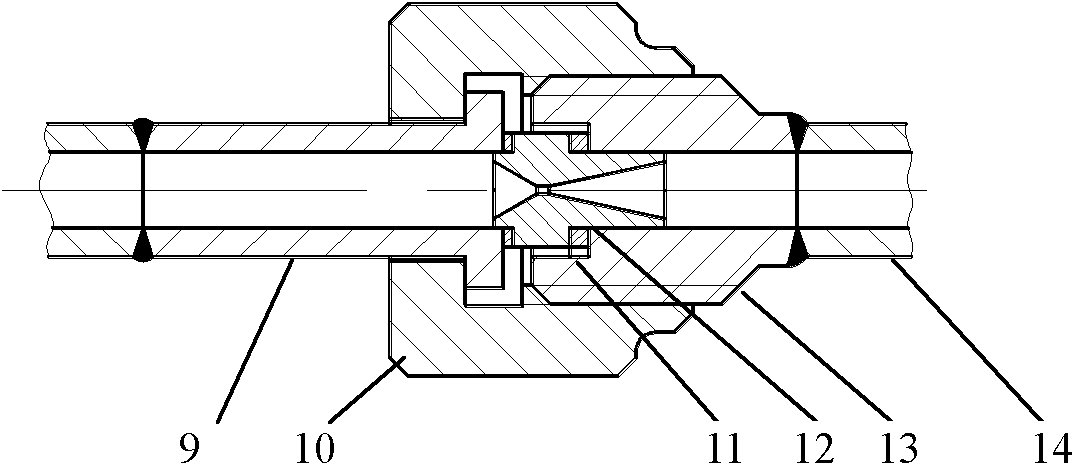

[0017] small combustion chamber 1 as figure 2 As shown, it mainly includes an oxygen nozzle 5, a hydrogen nozzle 6, an electric spark plug 7 and a combustion chamber housing 8. The oxygen nozzle 5 and the hydrogen nozzle 6 are combined into a coaxial direct-flow nozzle by welding, and are installed on the head of the combustion chamber housing 8 by threads; Enter the oxygen nozzle 5 and the hydrogen nozzle 6 through the sonic nozzle assembly 2; the electric spark plug 7 is installed on the side of the combustion chamber housing 8, and the tail end of the combustion chamber housing 8 is connected to two parallel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com