Method for replacing mine goaf gas with carbon dioxide

A carbon dioxide and goaf technology, applied in the direction of gas emissions, safety devices, mining equipment, etc., can solve the problems of difficult user acceptance and high cost of storage technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following specific embodiments.

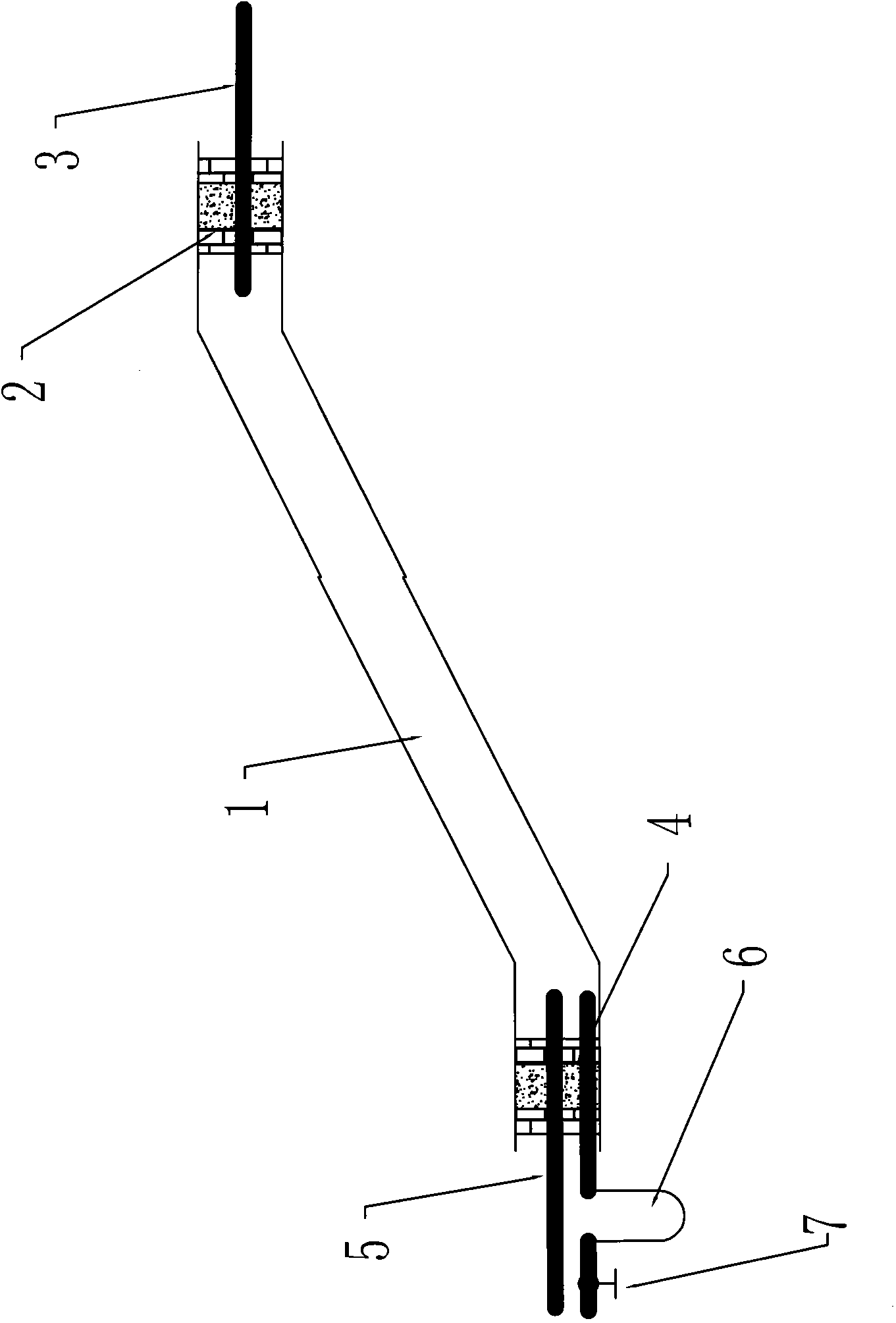

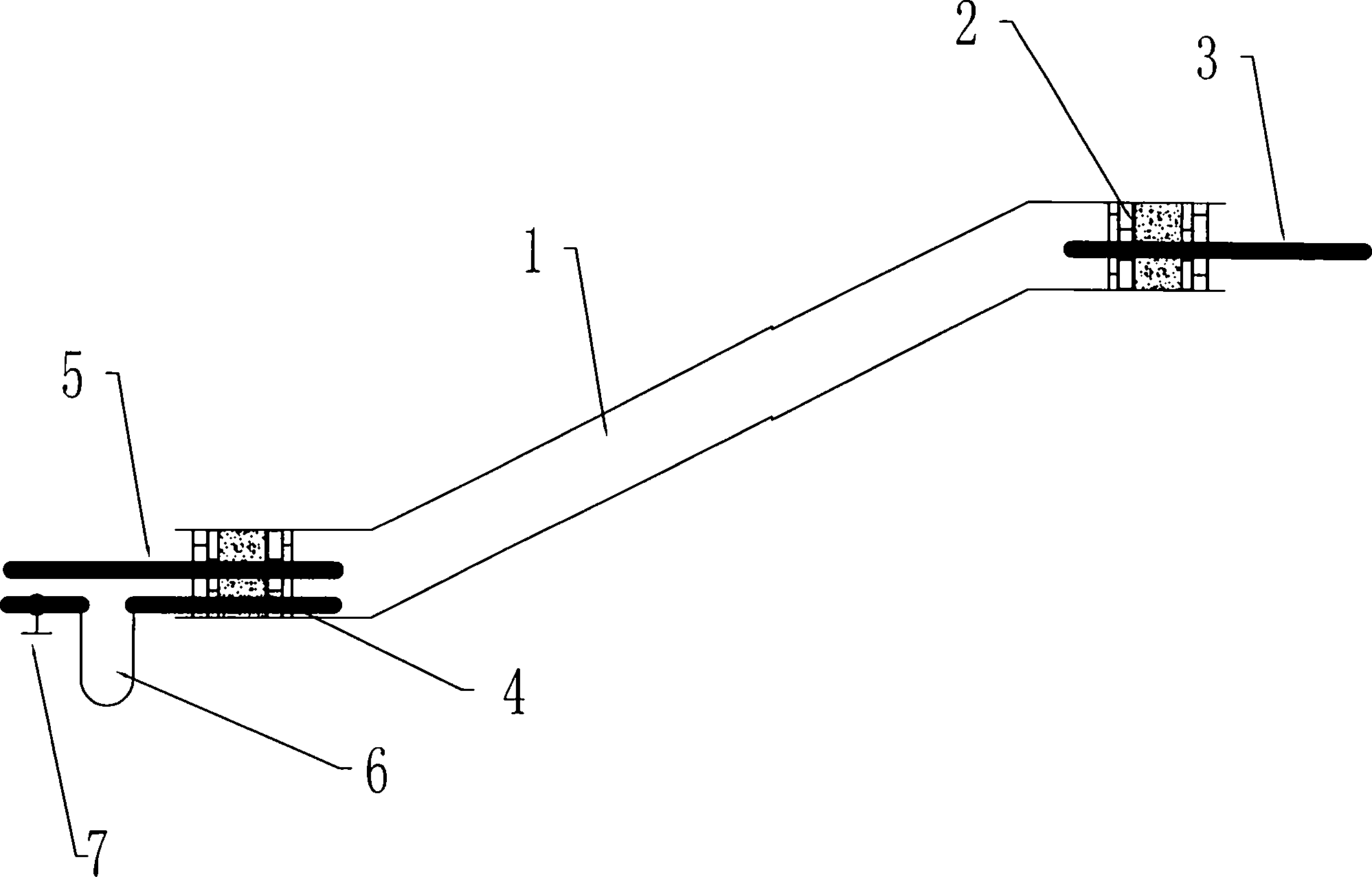

[0024] The goaf with a gas concentration of 40% is selected as the replacement goaf 1, and all the external exit roadways of the replacement goaf 1 are closed. like figure 1 As shown, a carbon dioxide intake pipe 5 is laid between the closed 4 reserved pipeline opening in the lower area and the carbon dioxide generating device, a gas output pipe 3 is laid between the sealed 2 reserved pipeline opening in the upper area and the gas utilization device, and the lower area A U-shaped drainage pipe 6 is arranged at the bottom of the airtight 4, and a valve 7 is arranged on the U-shaped drainage pipe 6. The U-shaped drainage pipe 6 is used to discharge and replace accumulated water in the goaf 1 and prevent gas from leaking out.

[0025] The carbon dioxide gas inlet pipe 5 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com