PVC floor and production method thereof

A floor and floor plate technology, applied in the direction of floor, building, building structure, etc., can solve the problems of excessive clearance, inconvenient transportation, poor plane effect, etc., to achieve difficult clearance and displacement, simple production method, and plane effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

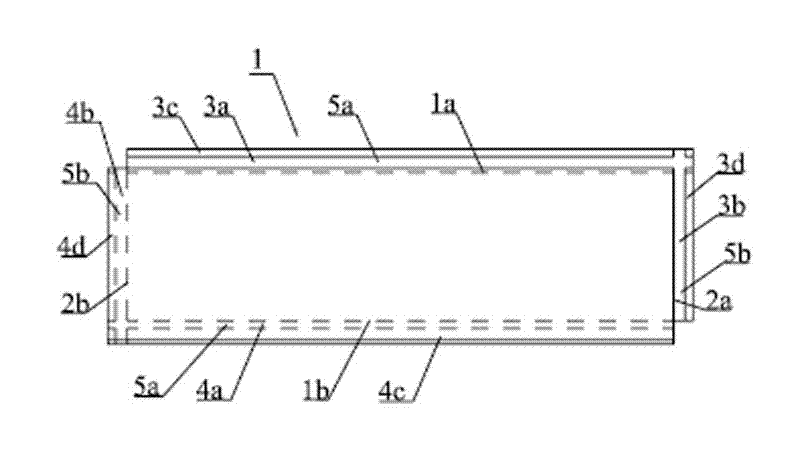

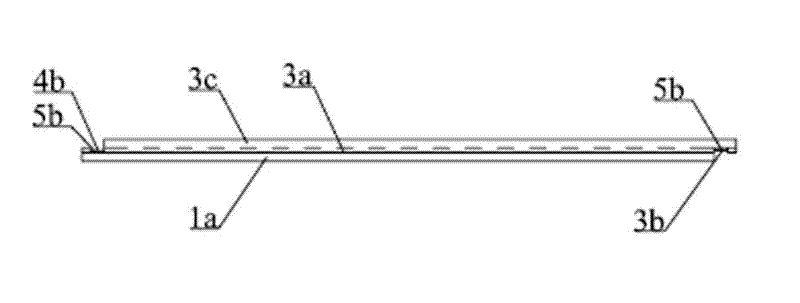

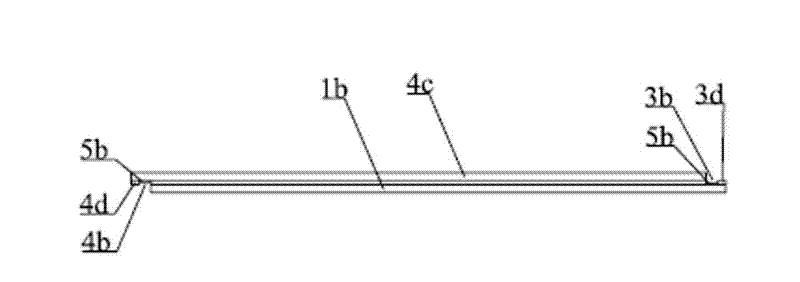

[0036] Such as Figures 1 to 4 As shown, the PVC floor according to this embodiment includes rectangular floorboards 1 . Floorboards 1 have connecting latches along opposite long sides 1a, 1b and opposite short sides 2a, 2b for locking one floorboard and a second floorboard together horizontally so that the floorboards in the joined state The plate and the second floor plate together define a horizontal plane (see Figure 7 and Figure 8 ), the connecting lock includes a first long groove 3a and a first short groove 3b that are opened on the front of the floorboard 1 and extend along one long side 1a and one short side 2a of the floorboard 1 respectively, and are opened on the floorboard 1 The opposite side and the second long groove 4a and the second short groove 4b extending along the other long side 1b and the other short side 2b of the floor board 1 respectively, and the flanges 3c, 3d, 4c, 4d located on the outside of each groove , wherein the convex edge 3c matche...

Embodiment 2

[0039] The PVC floor according to this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, the upper surfaces of the flanges 3c, 3d, 4c, and 4d located at the four sides of the floor board 1 are provided with a second There are three adhesive layers 5c, and the third adhesive layer 5c covers the entire upper surface of the flange. Compared with Example 1, the buckling stability of the PVC floor with this structure is further improved.

Embodiment 3

[0041] The PVC floor according to this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, the first adhesive layer 5a and the second adhesive layer 5b are not covered in a whole strip at the bottom of the corresponding groove Instead, it exists in the form of a plurality of first glue units 50a and second glue units 50b uniformly distributed along the extending direction of the groove. The thicknesses of the multiple first glue units 50a are consistent; the thicknesses of the multiple second glue units 50b are consistent. The PVC floor with this structure can also achieve the purpose of improving the fastening stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com