Method for producing steel reinforcement cage by using setting die

A technology of stereotyped molds and steel cages, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve problems such as low work efficiency, unreasonable connection of acoustic measuring tubes, time-consuming main reinforcement and stirrups, etc., to achieve fast and convenient construction, The effect of shortening the production cycle and ensuring the spacing of the main ribs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

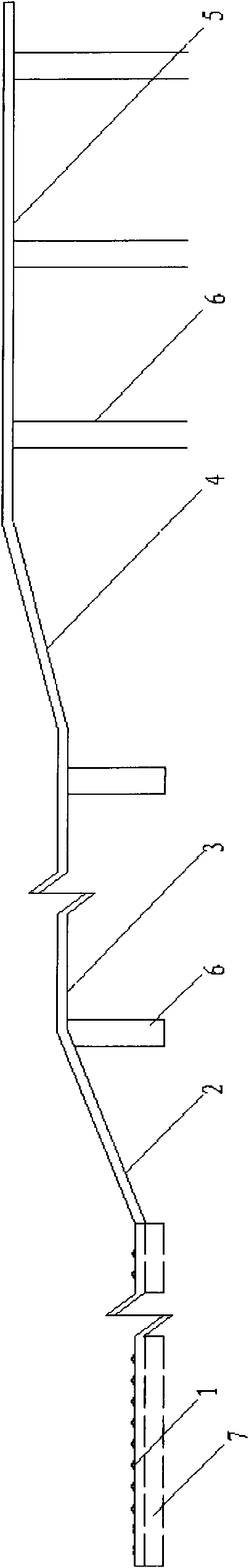

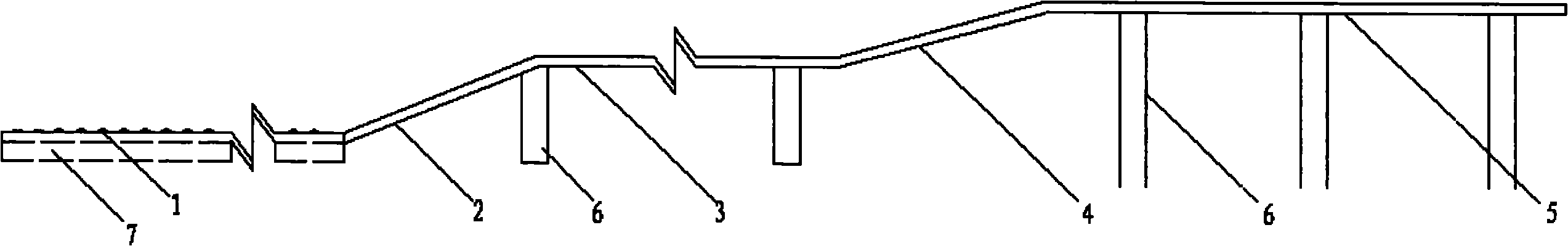

[0019] Referring to accompanying drawing, a kind of method that utilizes shaping mold to make reinforcement cage, comprises following construction steps:

[0020] (1), at first the reinforced cage 9 that is processed is placed on a plurality of frameworks that are juxtaposed and arranged at intervals, and each framework 7 is equidistantly provided with main reinforcement positioning cards 8 respectively, and the main reinforcement positioning clamps on each framework 7 are along the length of the reinforcement cage. The directions are arranged in several rows of straight lines, and the main reinforcement 11 of the reinforcement cage is stuck in the main reinforcement positioning card of the same row of straight lines;

[0021] (2), place a reinforcing bar 10 along the radial direction corresponding to a main bar on the top of the reinforcement cage, weld the main bar and the reinforcing bar; then push the reinforcing bar backwards in sequence, and weld each main bar of the rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com