Fluorine and silicon containing water and oil repellent finishing agent, preparation and application thereof

A finishing agent, fluorine-containing alkyl technology, used in fiber processing, textiles and papermaking, etc., can solve problems such as fluorine-containing carbon chain length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Embodiment 1

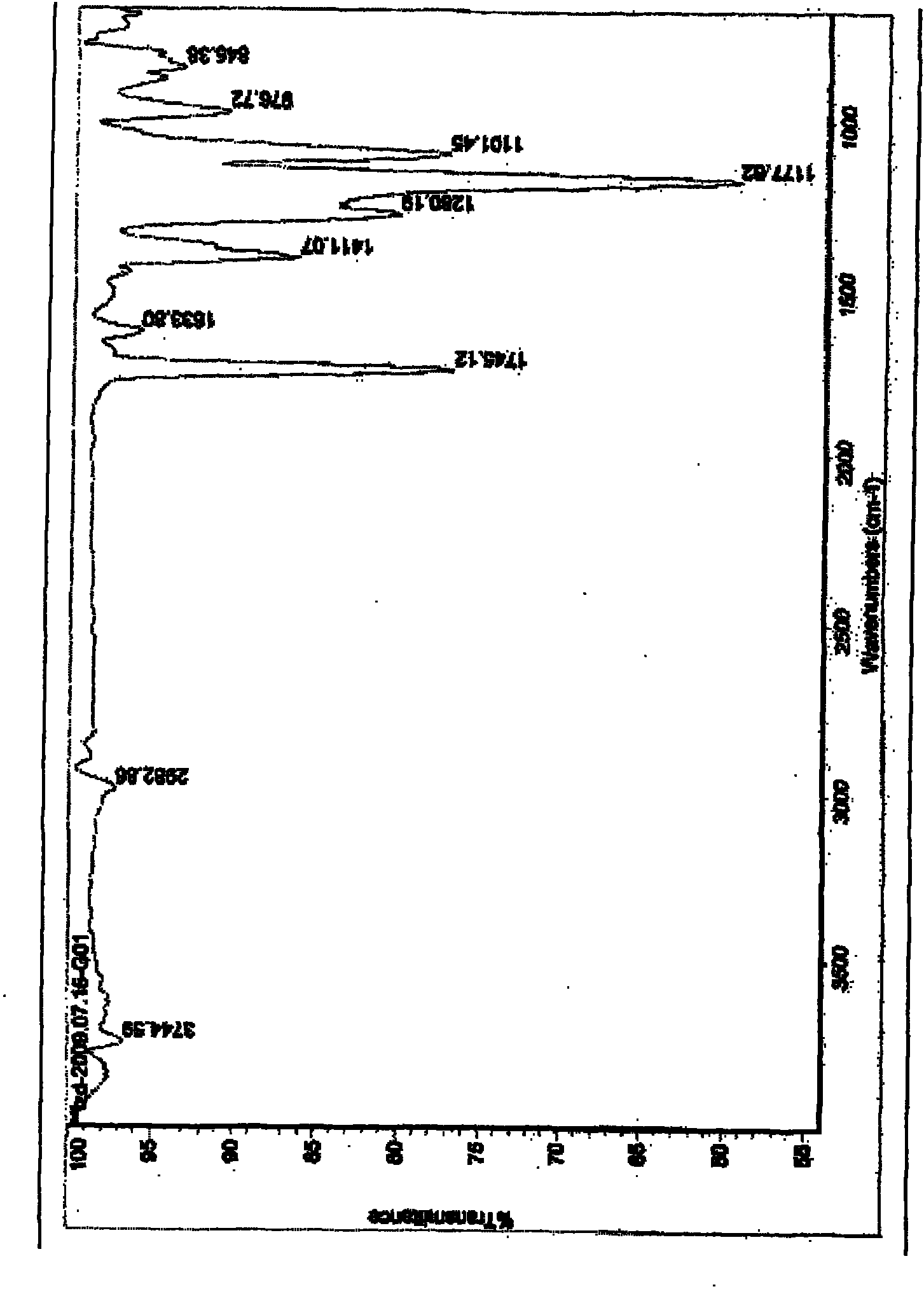

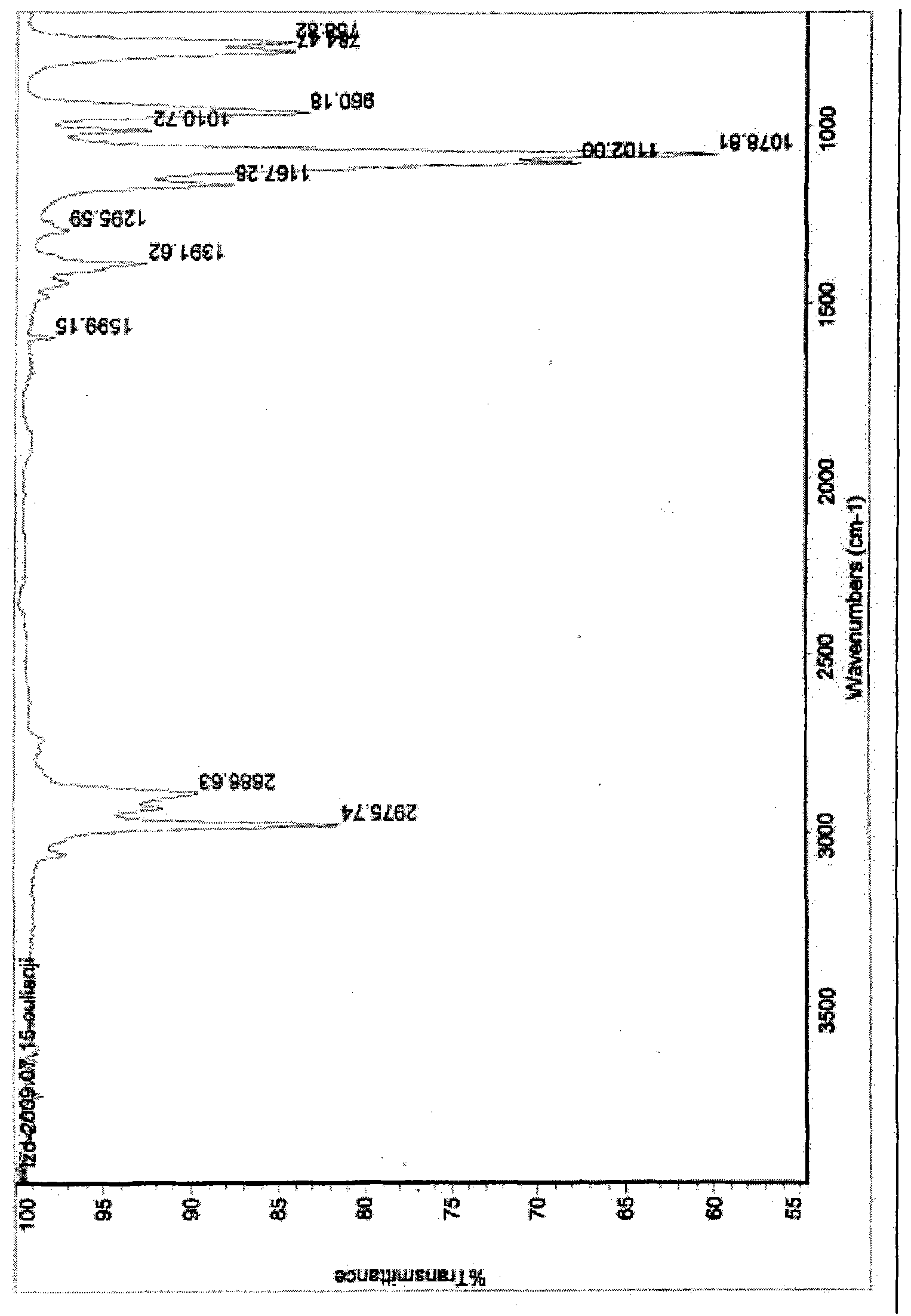

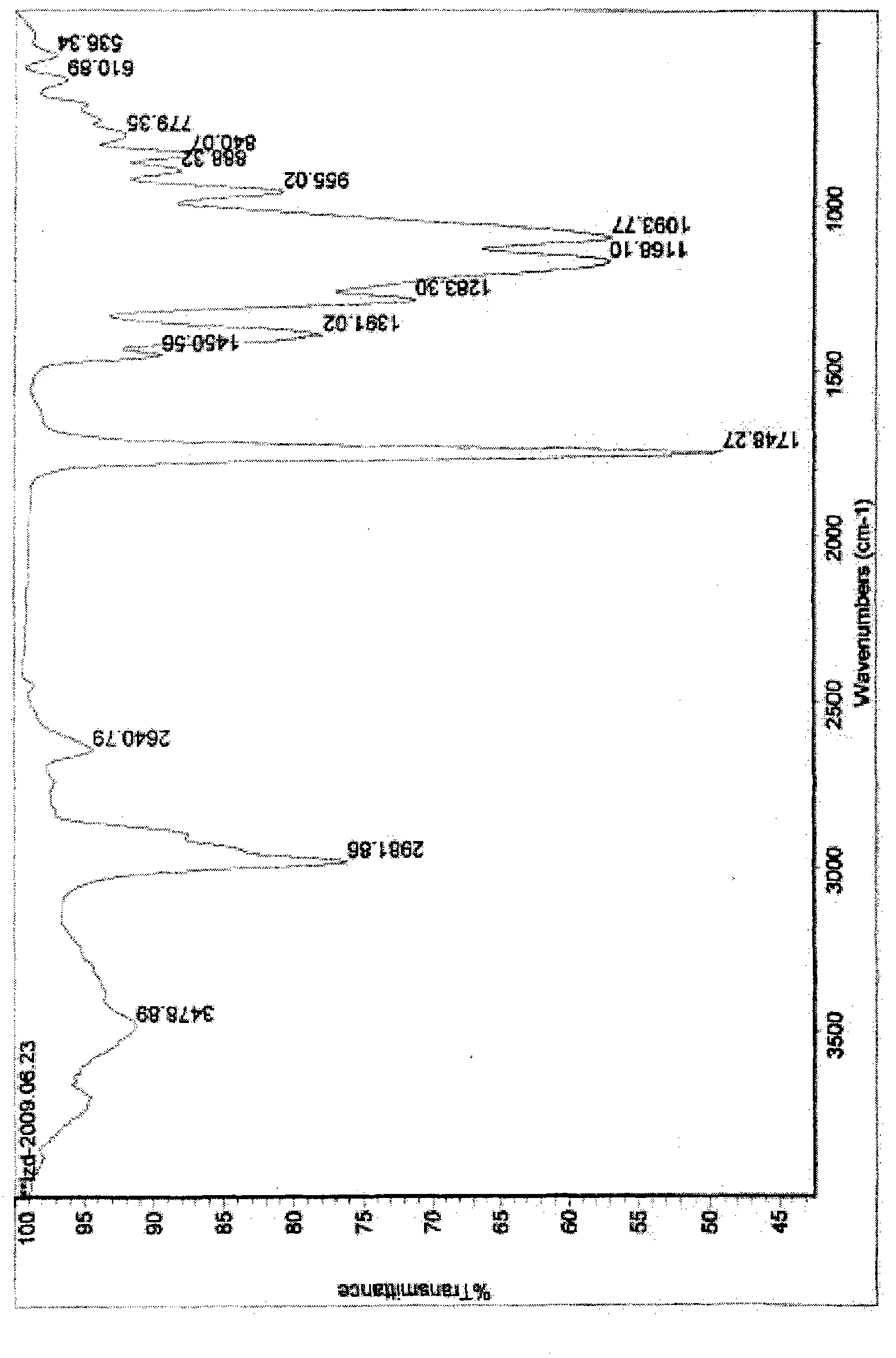

[0034] Install electric stirring, constant pressure funnel, and condenser on the three-necked flask, add 20ml of ethanol to the three-necked flask, and dissolve 0.09g of azobisisobutyronitrile (AIBN) in the remaining 20ml of ethanol and mix it with 13.14g of hexafluorobutyl acrylate and 3.05g of Vinyltriethoxysilane is miscible and loaded into a constant pressure funnel. Start heating, and turn on the electric stirring and condensed water, and start to add the raw material mixture dropwise after the ethanol forms a reflux. Observe the state of the reaction solution at any time, and after 8 hours of constant temperature reaction at the boiling point temperature, cool to room temperature and discharge. According to the dry matter method, the product was dried in an oven to constant weight to obtain product A. Measure its infrared spectrum and compare it with the raw material spectrum. And the glass transition temperature was tested by DSC to further prove the product A. see r...

Embodiment 2

[0037] Example 2: Refer to Example 1 for the operation steps, solvents, initiators and their dosages. The raw materials were replaced with 8.21 g of hexafluorobutyl acrylate and 9.52 g of vinyltriethoxysilane. The results are shown in Table 1.

Embodiment 3

[0039] Refer to Example 1 for the operation steps, solvents, initiators and their dosages. The raw materials were replaced with 13.14 g of hexafluorobutyl acrylate and 1.52 g of vinyltriethoxysilane. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com