Salt-tolerant latex cement slurry for well cementation

A cement slurry and salt-resistant technology, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of ordinary latex cement slurry not being resistant to salt and restricting the use of latex cement slurry, so as to reduce the transportation burden and reduce the operation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Measure the components of the salt-resistant grout according to Table 2, prepare the salt-resistant latex grout according to GB / T 19139-2003, and conduct the performance test of the grout. The G-grade cement in Table 2 is the high sulfur resistance (HSR) G-grade cement produced by Sichuan Jiahua Enterprise (Group) Co., Ltd.; the silica fume is produced by Tianjin Yanshan Superfine Mineral Powder Factory; Produced by Star Engineering Technology Co., Ltd.; AMPS-containing polymer fluid loss reducer is BXF-200L produced by Tianjin Zhongyou Boxing Engineering Technology Co., Ltd.; 1-hydroxyethylidene-1,1-diphosphoric acid is produced by Shandong Heli Water Treatment Co., Ltd. Production; polycondensation products of naphthalene sulfonate and formaldehyde, aldehyde and ketone condensation products are produced by Tianjin Red Sun Chemical Co., Ltd., trade names are UNF and USZ respectively; phosphate defoamer is Changhao Trading Co., Ltd., Shunde District, Foshan Cit...

Embodiment 2

[0018] Embodiment 2 Measure each component of the salt-tolerant cement slurry according to Table 3, prepare the salt-tolerant latex cement slurry according to GB / T 19139-2003 and carry out the cement slurry performance test. The experimental results are shown in Table 3: Table 3 Salt-tolerant latex cement slurry formula and performance Note: c: See No. 7 in Table 1 for the composition of salt-tolerant latex; d: See No. 9 in Table 1 for the composition of salt-tolerant latex.

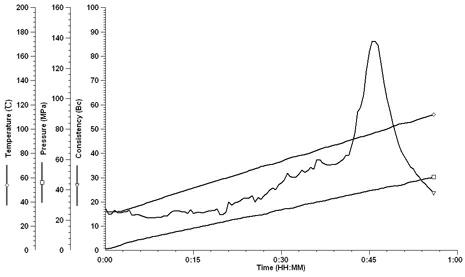

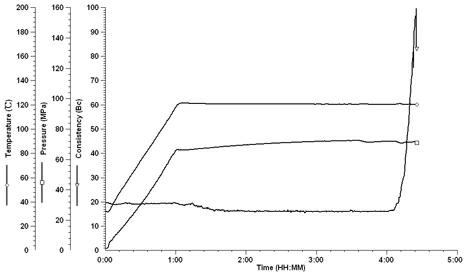

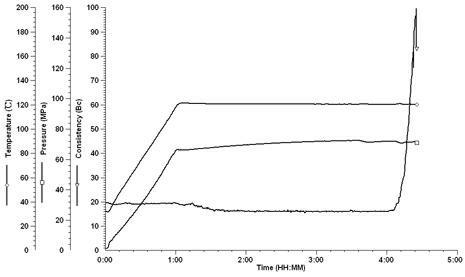

[0019] For the comparison example, take the salt-tolerant latex cement slurry marked with * in Table 3, draw its thickening curve, and compare it with the thickening curve of ordinary latex cement slurry. The results are shown in figure 1 and figure 2 .

[0020] Depend on figure 1 It can be seen from the figure that the thickening curve of ordinary latex cement slurry has "bulging phenomenon", and the cement slurry cannot be pumped if the consistency is greater than 70Bc, thus endangering the safety...

Embodiment 3

[0021] Embodiment 3 Measure each component of cement slurry according to Table 4, prepare seawater latex cement slurry according to GB / T 19139-2003 and carry out cement slurry performance test, the experimental results are shown in Table 4: latex cement slurry and performance of table 4 seawater mixing slurry Note: e: For the composition of salt-tolerant latex, see Table 1, No. 10; f: For the composition of salt-tolerant latex, see Table 1, No. 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com