Hydroxypropylmethylcellulose having high thermal gel strength, method for producing the same and food comprising the hydroxypropylmethylcellulose

A technology of hydroxypropyl methylcellulose and hydroxypropoxy, which is applied in the field of hydroxypropyl methylcellulose, can solve the problem that methylcellulose cannot be completely dissolved, and achieve excellent shape retention and high-heat gelation Effect of temperature, high heat gel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

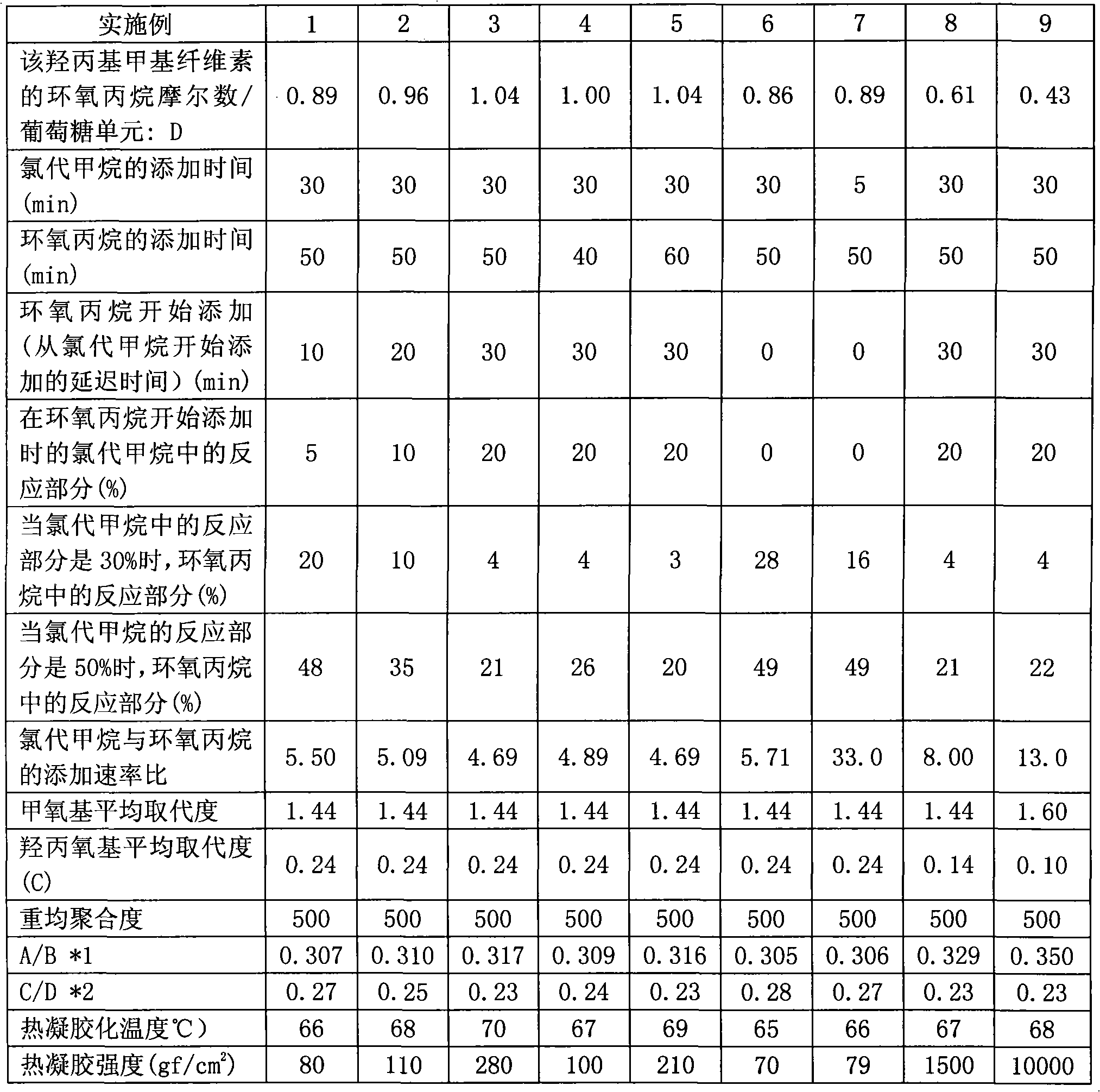

[0040] High-purity and soluble pulp derived from wood (manufactured by Nippon Paper Industries, Co., Ltd.) was ground into powder using a roller mill, then sieved through a sieve with 600 μm mesh, and sieved at a rate of 10 g / min. Feed at a constant speed into a S1 model biaxial kneader KRC Kneader (manufactured by Kurimoto, Ltd.; paddle diameter: 25mm, outer diameter: 255mm, L / D=10.2, inner volume: 0.12L, rotational speed: 100rpm) . Simultaneously, an aqueous solution of 49% by weight of sodium hydroxide was supplied at a constant rate of 13.7 g / min from the inlet of the pulp supply port to obtain alkali cellulose containing an aqueous alkali solution added to the cellulose . Of the alkali cellulose obtained by continuous operation for about 30 minutes, 561 g aliquots (230 g of cellulose) were added to a pressure vessel equipped with a plowshare type internal stirring blade. The vessel was depressurized to -97 kPa and then returned to atmospheric pressure by adding nitrogen...

Embodiment 2

[0047] Perform the same procedure as in Example 1, except that 20 minutes after starting to add methyl chloride, start to use a pressure pump to add propylene oxide to the reactor, and adjust the total amount of propylene oxide added to make hydroxypropoxy The average degree of substitution is 0.24. The results are shown in Table 1.

Embodiment 3

[0049] Perform the same procedure as in Example 1, except that 30 minutes after the addition of methyl chloride, start to use a pressure pump to add propylene oxide to the reactor, and adjust the total amount of propylene oxide added so that the hydroxypropoxy The average degree of substitution was 0.24. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com