Low-cost carbon fiber reinforced concrete and preparation method and application thereof

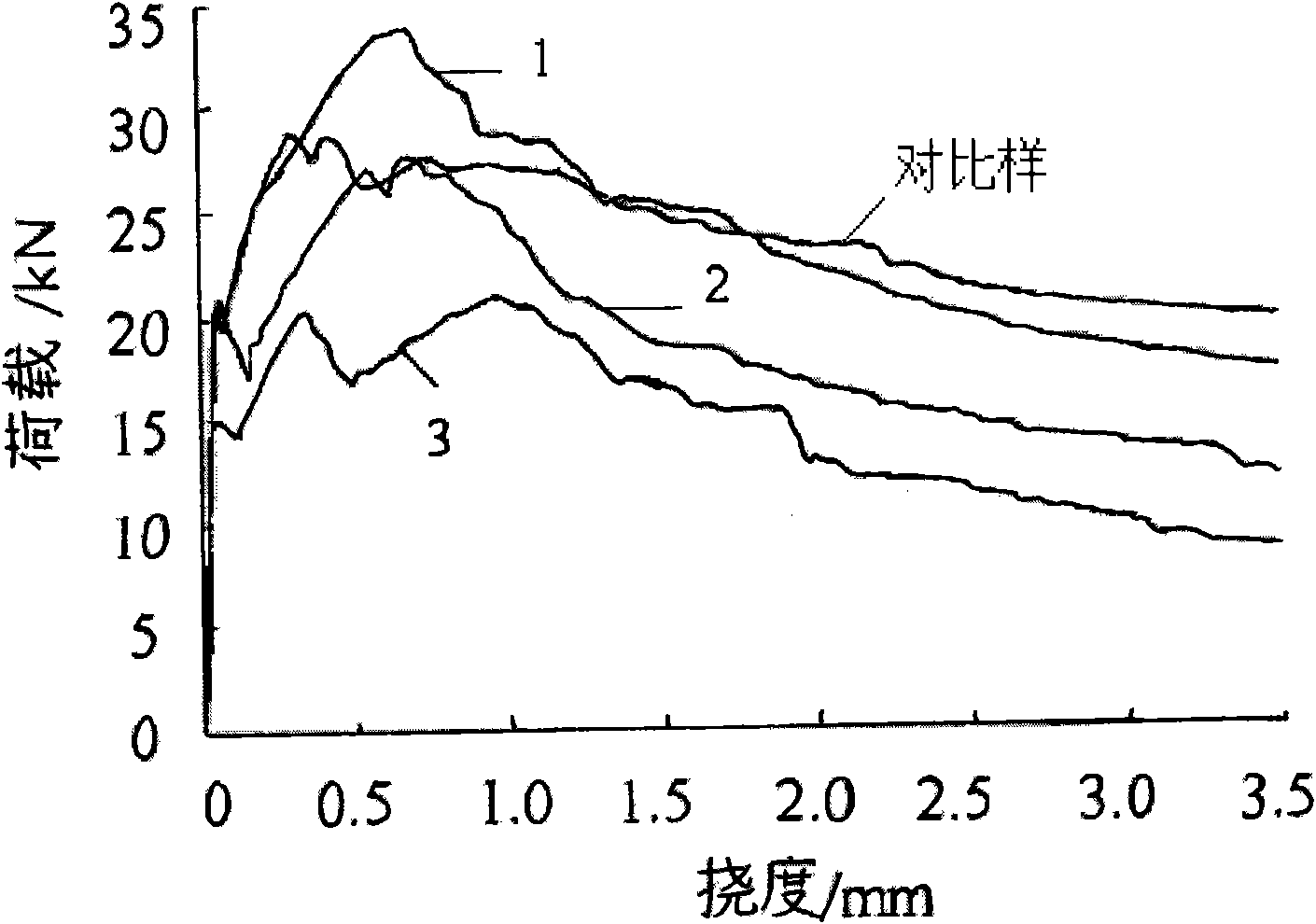

A technology of reinforced concrete and carbon fiber, which is applied in the field of building materials, can solve the problems of application limitations and failure to promote the large-scale application of carbon fiber, and achieve the effects of simple preparation process, high toughness, and reduced preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the low-cost carbon fiber reinforced concrete provided by the present invention may comprise the following steps:

[0037] 1) Mix low-cost carbon fiber (F) and dispersant (B) thoroughly first, then add to cement (A) and mix evenly;

[0038] 2) Put the sand, stone (E), and the mixture obtained in step 1) into the mixer in turn for dry mixing, then add the polycarboxylate water reducer (C) to the mixing water (D) and mix evenly, and then mix them together Add it into the blender and continue to stir, and get the product after mixing.

[0039] In the above preparation method, the stirring method in step 2) is: after adding the mixture obtained in sand, stone (E) and step 1), start the mixer for dry mixing for 30 seconds, stop the mixer, and then premix the Add the mixing water with polycarboxylate superplasticizer and continue stirring for 180 seconds.

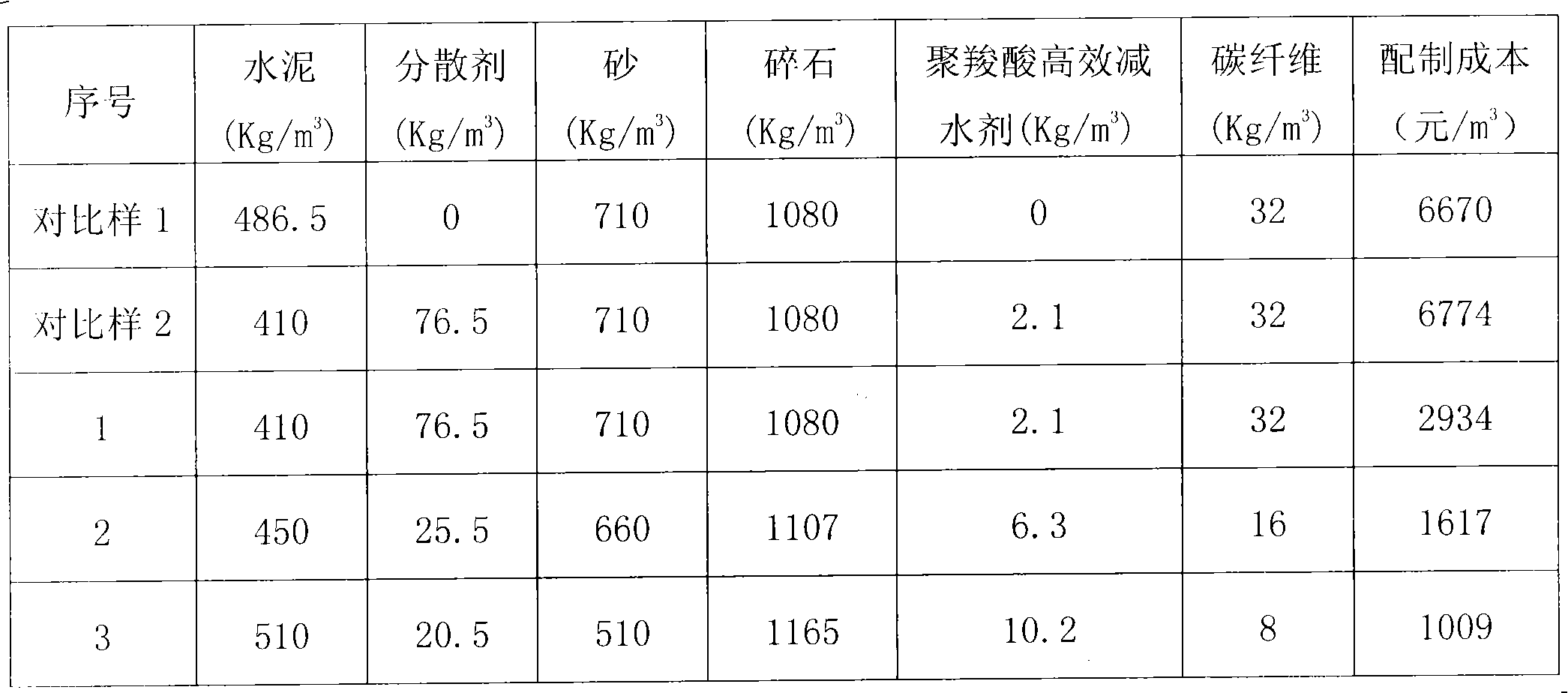

Embodiment 1

[0042] Embodiment 1: Preparation of low-cost carbon fiber reinforced concrete (calculated by 30L)

[0043] The following method is used to prepare low-cost carbon fiber reinforced concrete, and the specific method includes the following steps:

[0044] 1) Weighing and retrieving materials: PI cement 12.3Kg (purchased from Beijing Xingfa Cement Co., Ltd.); dispersant fly ash 2.3Kg (purchased from Ausmelt Technology (Beijing) Co., Ltd.); agent (99% allyl alcohol polyoxyethylene ether+1% carbon alcohol) 62g (purchased from Beijing Haima Chemical Co., Ltd.); water 3.7Kg (tap water); sand 21.3Kg; stone 32.4Kg; low-cost carbon fiber 960g (purchased from Jiangsu Zhongfu Shenying Carbon Fiber Co., Ltd.).

[0045]2) Mix the low-cost carbon fiber and dispersant thoroughly first, then add it to the cement and mix evenly. The mixing process is carried out in a mixer, and the mixing time is not less than 1 minute to ensure uniform mixing.

[0046] 3) In the first layer, sand and stone ar...

Embodiment 2

[0048] Embodiment 2: Preparation of low-cost carbon fiber reinforced concrete (calculated by 30L)

[0049] The following method is used to prepare low-cost carbon fiber reinforced concrete, and the specific method includes the following steps:

[0050] 1) Weighing and retrieving materials: PI cement 13.5Kg (purchased from Beijing Xingfa Cement Co., Ltd.); dispersant slag 770g (purchased from Osmet Technology (Beijing) Co., Ltd.); sand 19.8Kg; stone 33.2Kg; water 4.7Kg (tap water); Polycarboxylate superplasticizer (polyether modified silicon of 95% polyethylene glycol acrylic acid ester+5%) 189g (purchased from Beijing Haima Ding Co., Ltd.); Low-cost carbon fiber 480g (purchased from Jiangsu Zhongfu Shenying Carbon Fiber Co., Ltd.).

[0051] 2)-3) are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com