System and method for removing natural organic substances and odor-induced substances in micro polluted water

A technology for natural organic matter and slightly polluted water, which is applied in the system field of removing natural organic matter and odor-causing substances in slightly polluted water, can solve problems such as insufficient technical reserves, achieve economical, effective, simple and easy implementation, increase membrane flux, and reduce leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

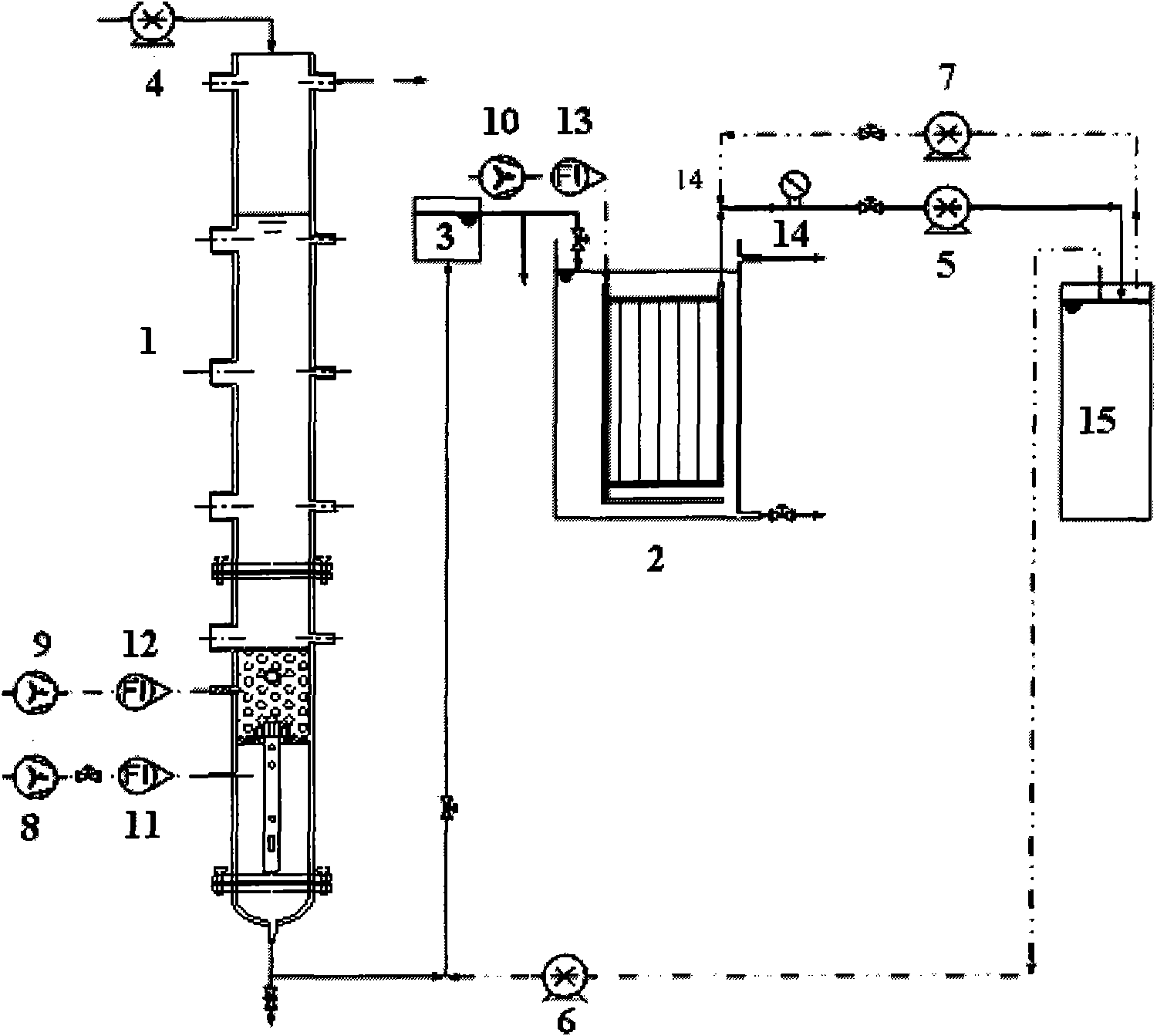

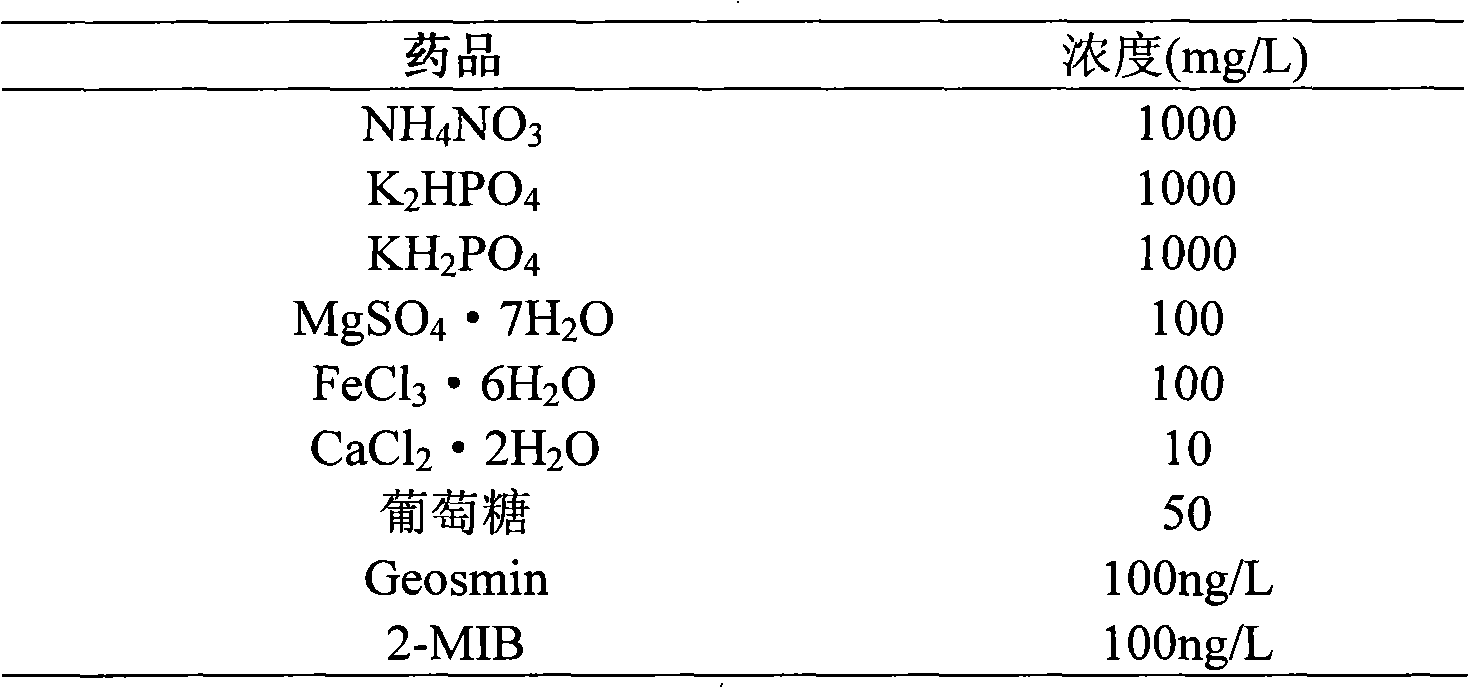

[0057] (1) The simulated lake water to be treated is self-distributed, and the formula is shown in Table 2. Inoculate microorganisms from Taihu Lake. The microorganisms are mixed microorganisms. They are taken from the sediment on the shore of Taihu Lake in late spring and early summer. After passing through 200 mesh screening, they are directly connected to the biological aerated filter tower. The air aeration pump provides oxygen, the aeration rate is 120-200mL / min, add 1L of BH medium and 500ml of glucose every day, and drain 1L; after 3 weeks, start the biological aeration filter 1,

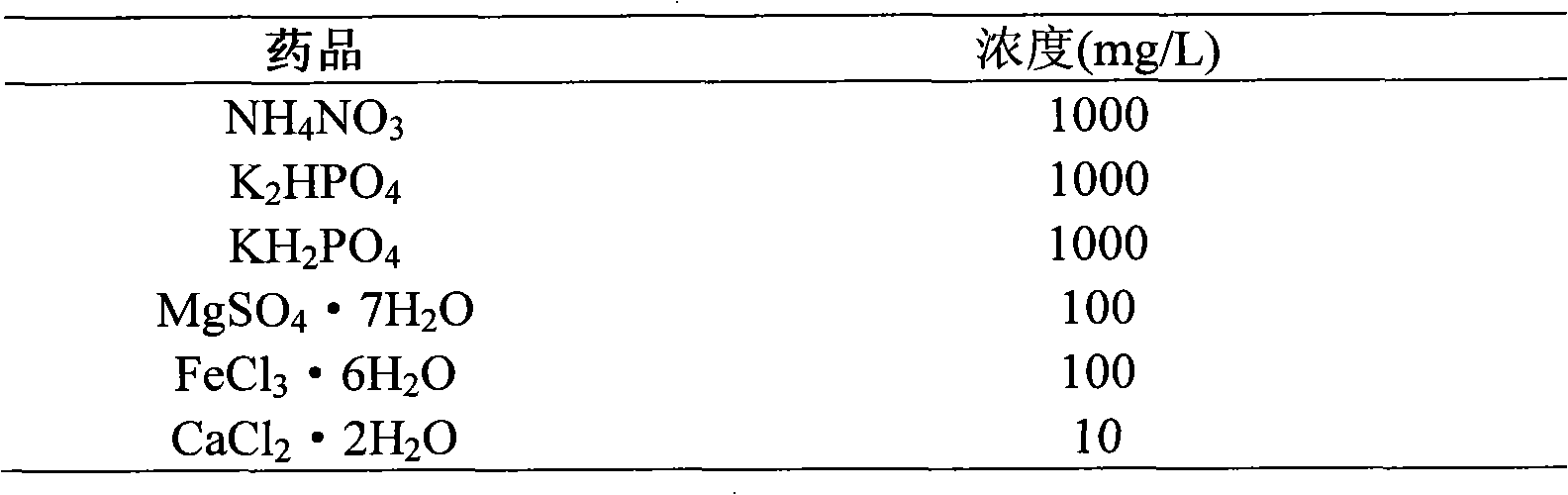

[0058] The BH medium is composed as follows: NH 4 NO 3 : 1000mg / L, K 2 HPO 4 : 1000mg / L, KH 2 PO 4 : 1000mg / L, MgSO 4 ·7H 2 O: 100mg / L, FeCl 3 ·6H 2 O: 100mg / L, CaCl 2 2H 2 O: 10mg / L;

[0059] Table 2 Self-dispensing water quality formula

[0060]

[0061] (2) Send the slightly polluted source water (influent index see Table 2) to the biological aerated filter tower, the filte...

Embodiment 2

[0065] (1) This step is the same as in Example 1.

[0066] (2) Slightly polluted source water (see Table 2 for water intake index) is sent into biological aerated filter tower 1 by water intake pump 4, and filter tower packing adopts granular activated carbon, and the amount of slightly polluted source water in biological aerated filter tower 1 The hydraulic retention time is 120min, and the gas-water ratio is 1:1. The effluent enters the regulating tank 3, and then enters the ultrafiltration membrane module 2 through gravity. The gas-water ratio in the ultrafiltration membrane module 2 is 16:1. The membrane pore size is 0.01 micron, and the material is a polyvinyl chloride external ultrafiltration membrane module. The flux is 26L / m 2 · h, the pressure changes within 0.01-0.03Mpa. Filtrate for 60 minutes, backwash automatically, and the effluent from the ultrafiltration membrane module enters the clean water pool 15, where it can be sent to the user after being disinfected i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com