Double-roller bed conveyor device

A technology of conveying device and driving roller, applied in the direction of roller table, conveyor objects, transportation and packaging, etc., can solve the problems of uneven running of carbon block, stuck carbon block, affecting smooth transportation of carbon block, etc. The effect of easy maintenance, lightening of bearing capacity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

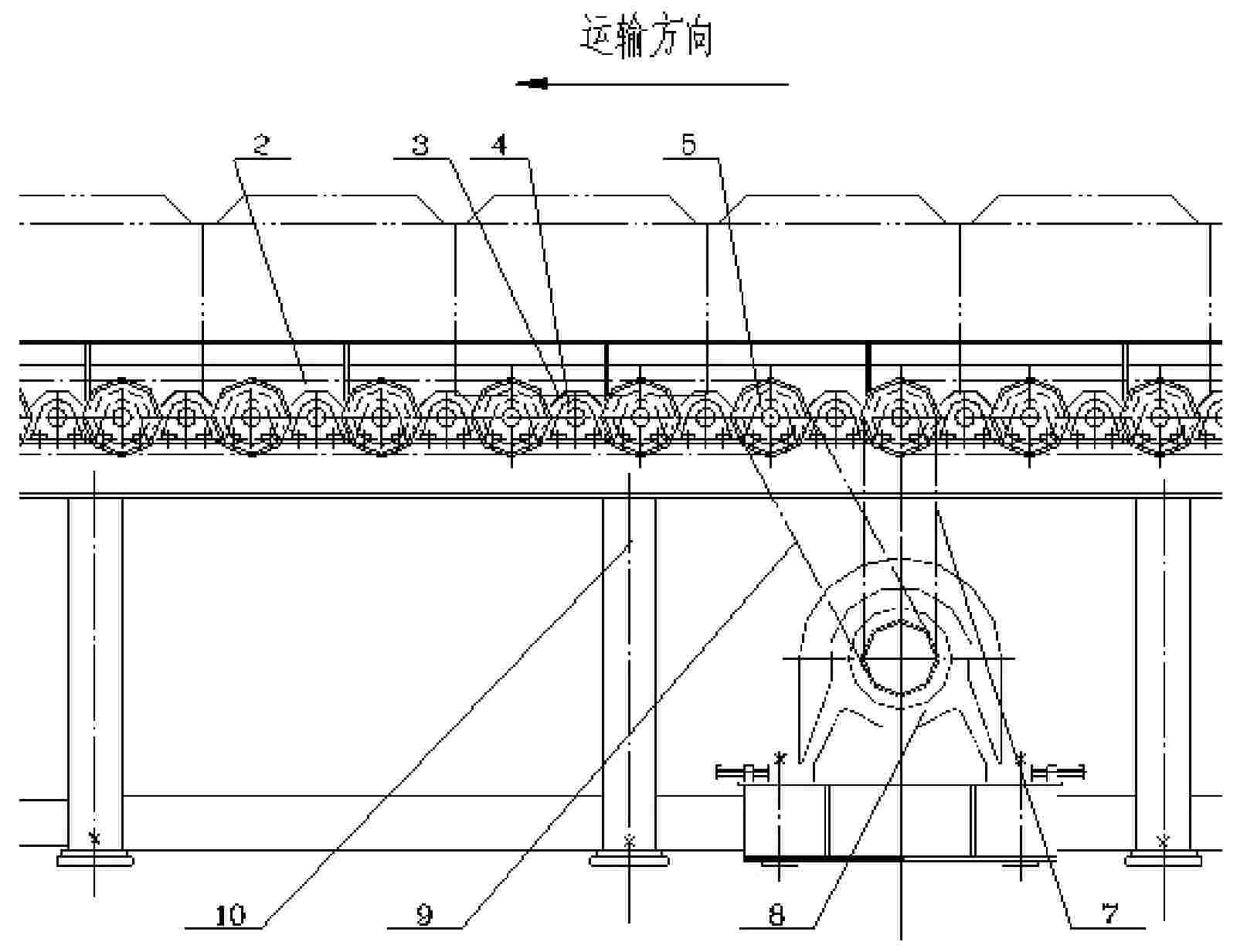

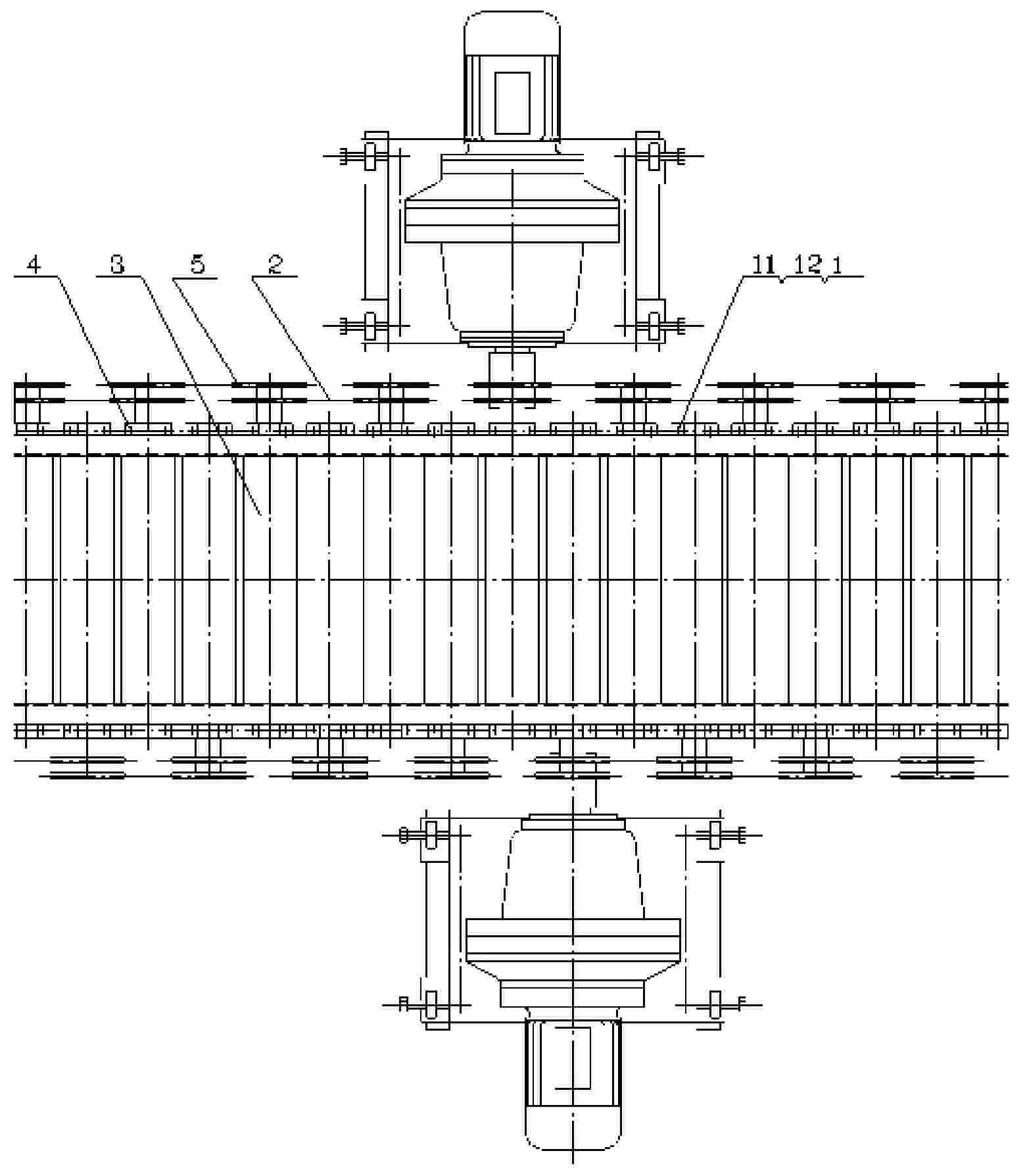

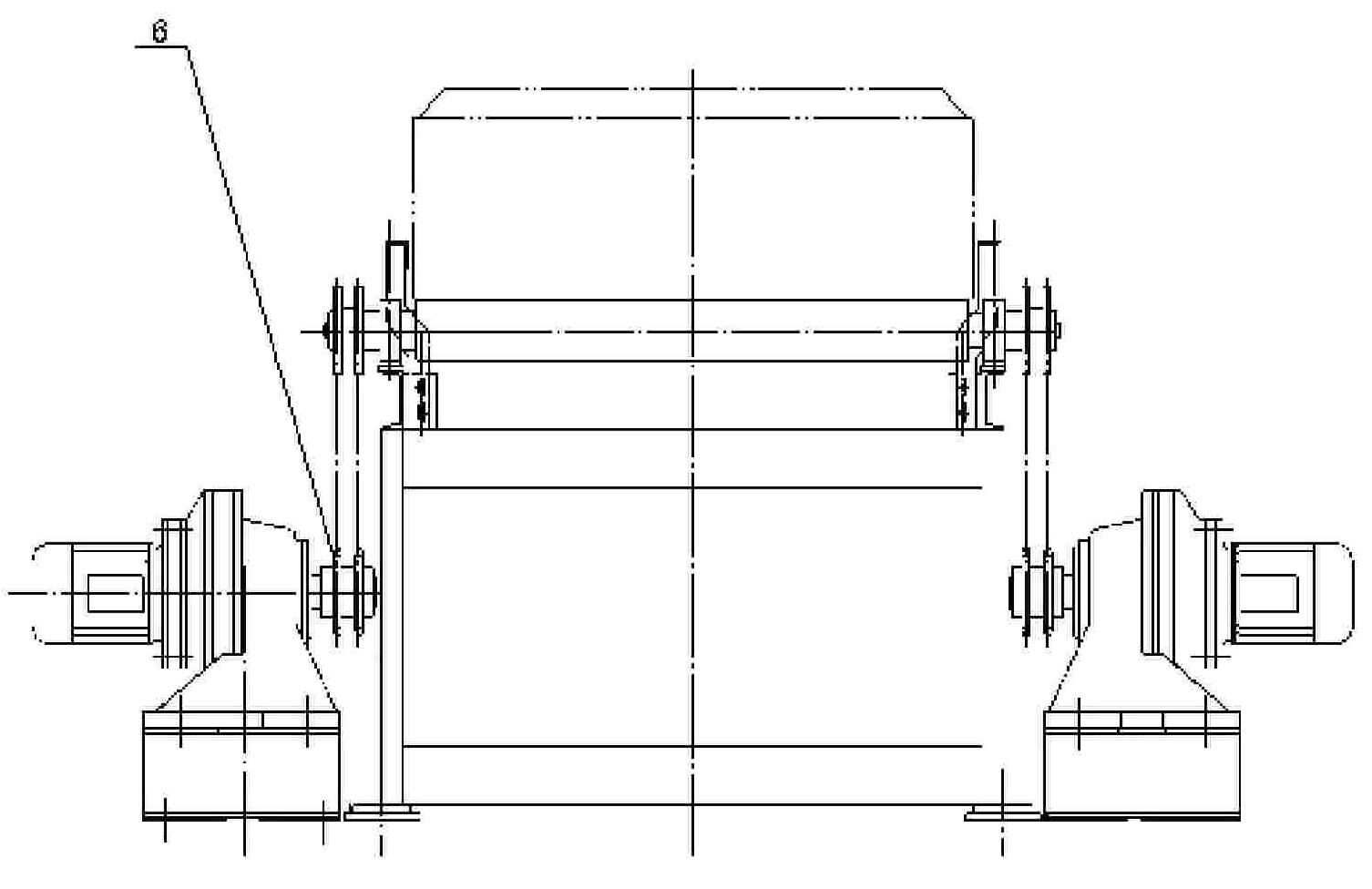

[0011] Embodiments of the present invention: as attached figure 1 , 2 , 3, install two reducers 8 on the left and right sides of the frame 10 and stagger a roller (see attached figure 2 , 3 ). The output shafts of two speed reducers 8 are loaded onto double row sprockets 6 respectively. One end of drive roller 3 is equipped with double-row sprocket 5 and a belt seat bearing 4, and the other end is only equipped with a belt seat bearing 4. Seat bearing 4 is installed on the frame with bolt 11, nut 12, spring washer 1 respectively (see attached figure 2 ). Hang one end of the drive chain 7 and 9 on the double row sprocket 6 of the output shaft of the reducer, and hang the other end on the double row sprocket 5 installed on the drive roller 3, and finally pass the double row sprocket 5 through the traction chain 2 Connected to achieve the purpose of transmission.

[0012] When conveying, all carbon blocks should not be smaller than four rollers respectively touching the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com