Method and device for disassembling electrical-electronic apparatuses

A technology for electronic equipment and power, applied in the field of decomposing power electronic equipment and devices, can solve problems such as damage, pollution, and fragile backlight fluorescent tubes, and achieve the effect of less separation and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will now be described based on the aforementioned drawings.

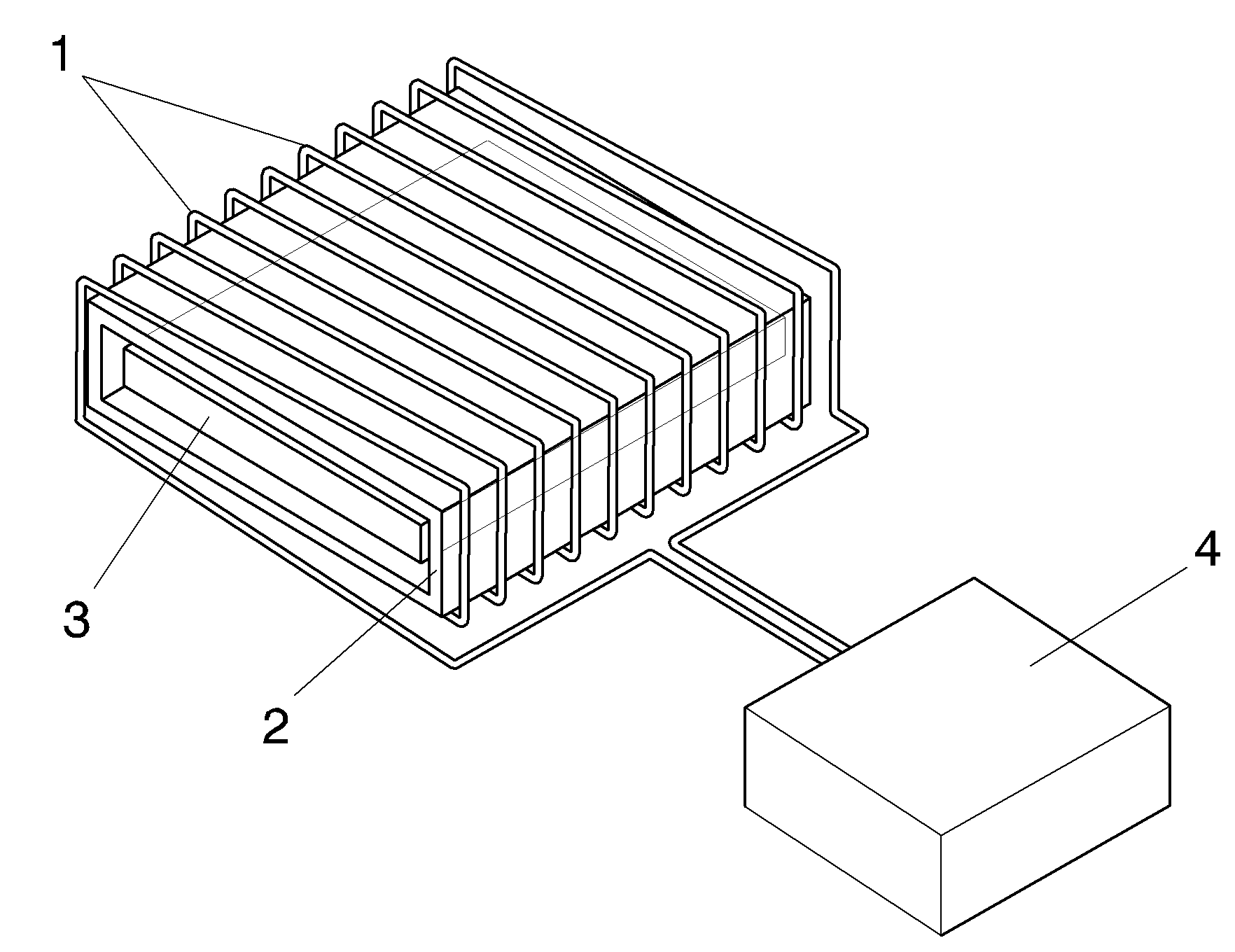

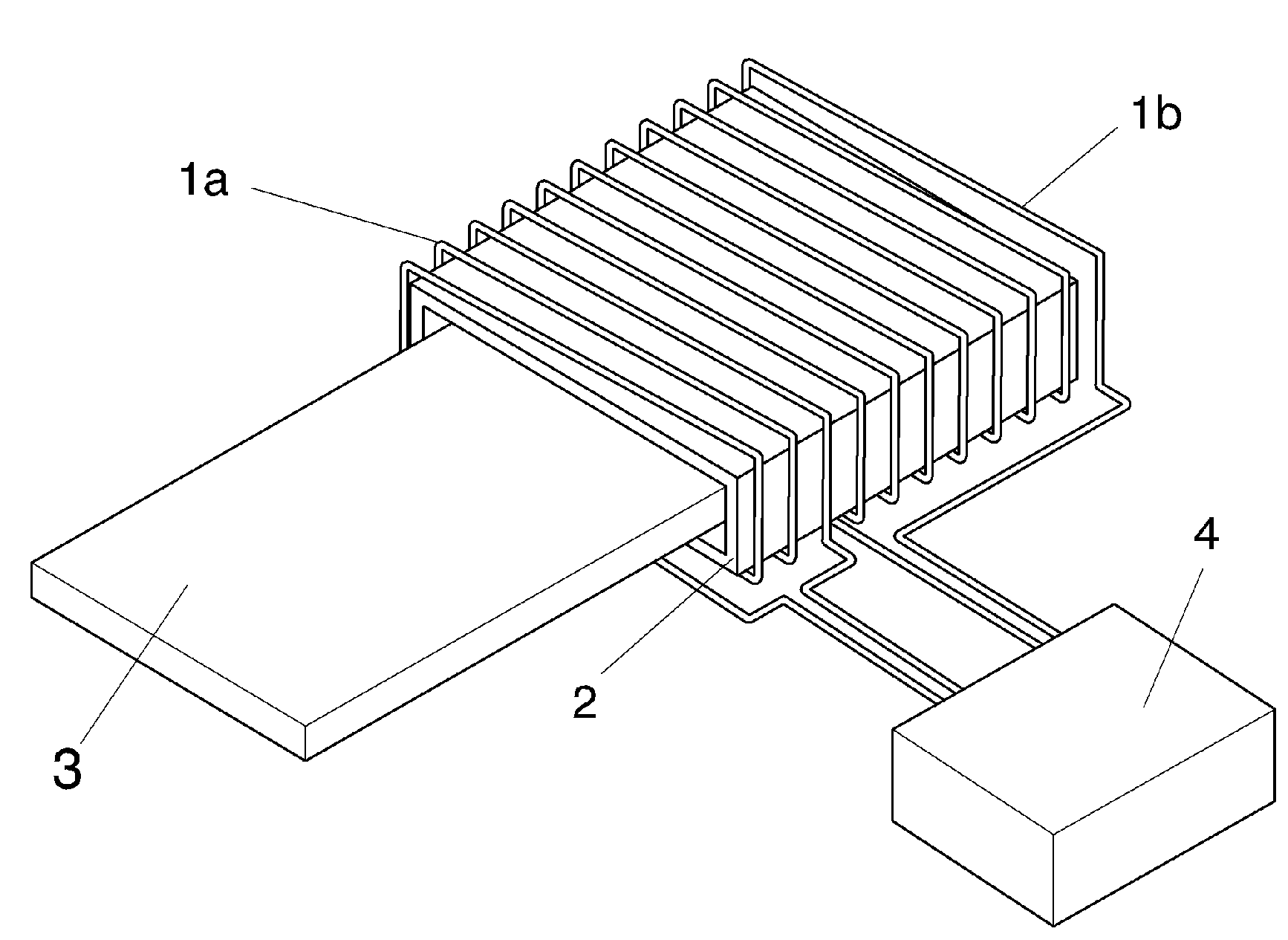

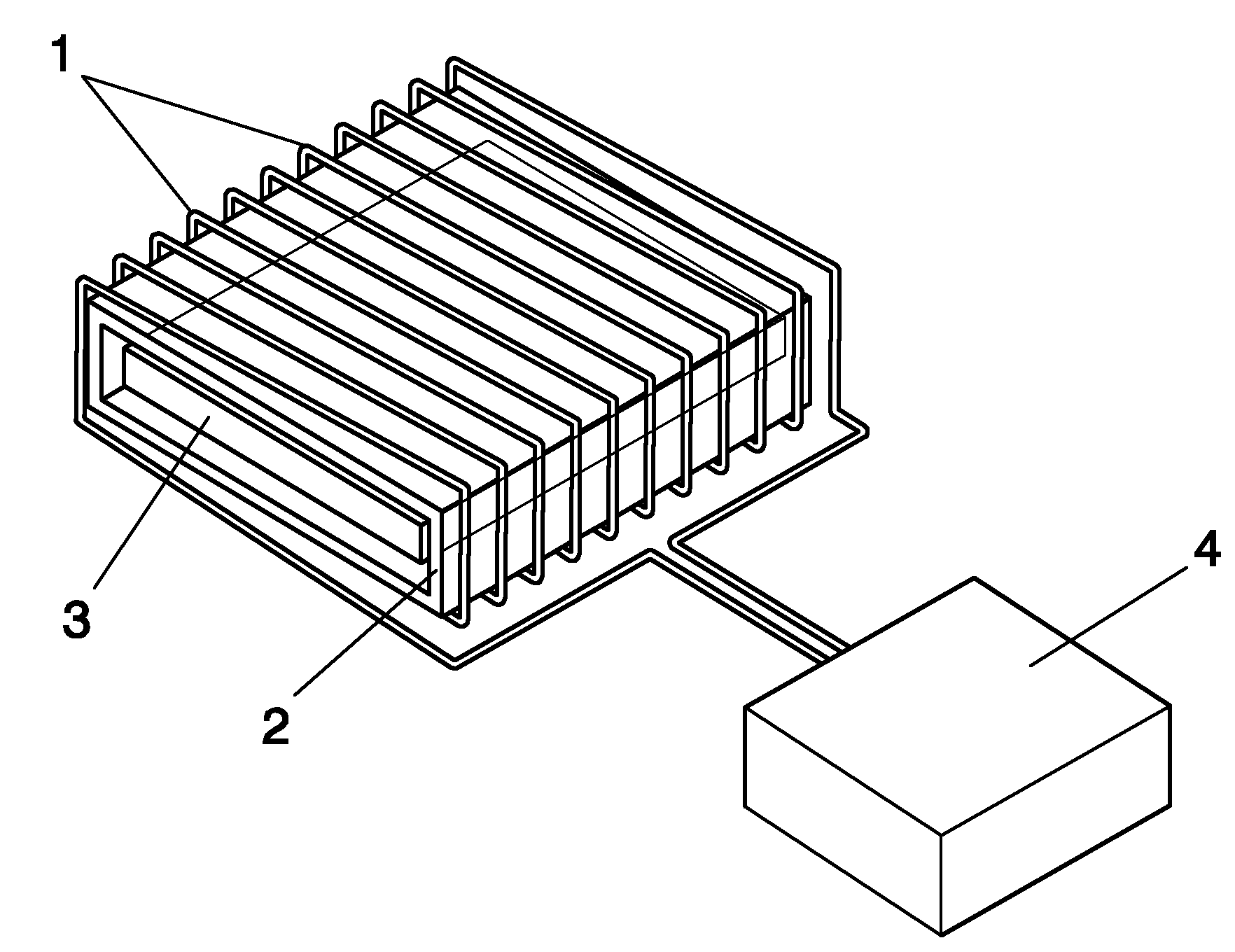

[0031] The device of the invention comprises an induction coil 1 comprising a set of turns wound around a tubular body 2 inside which the device 3 to be dismantled is housed. The induction coil 1 is connected to an alternating current generator 4 .

[0032] In a preferred embodiment example, the device 3 comprises a plasma display device such that the tubular support 2 has a rectangular cross-sectional configuration complementary to the rectangular cross-section presented by the plasma display device.

[0033] When the alternating current generator 4 is energized, this configuration allows current to circulate through the coil 1 to induce a current in the metal plates of the plasma display device, which heats the display device by means of convection, radiation and conduction and expand to the surrounding space. As a result, the connection points of the different sheets making up the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com