Double-belt non-deflection rubber belt vacuum filter

A vacuum filter and rubber belt technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of low filtration efficiency of equipment, increase of system comprehensive cost, cumbersome system maintenance work, etc., and achieve simple structure , ensuring stability and preventing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

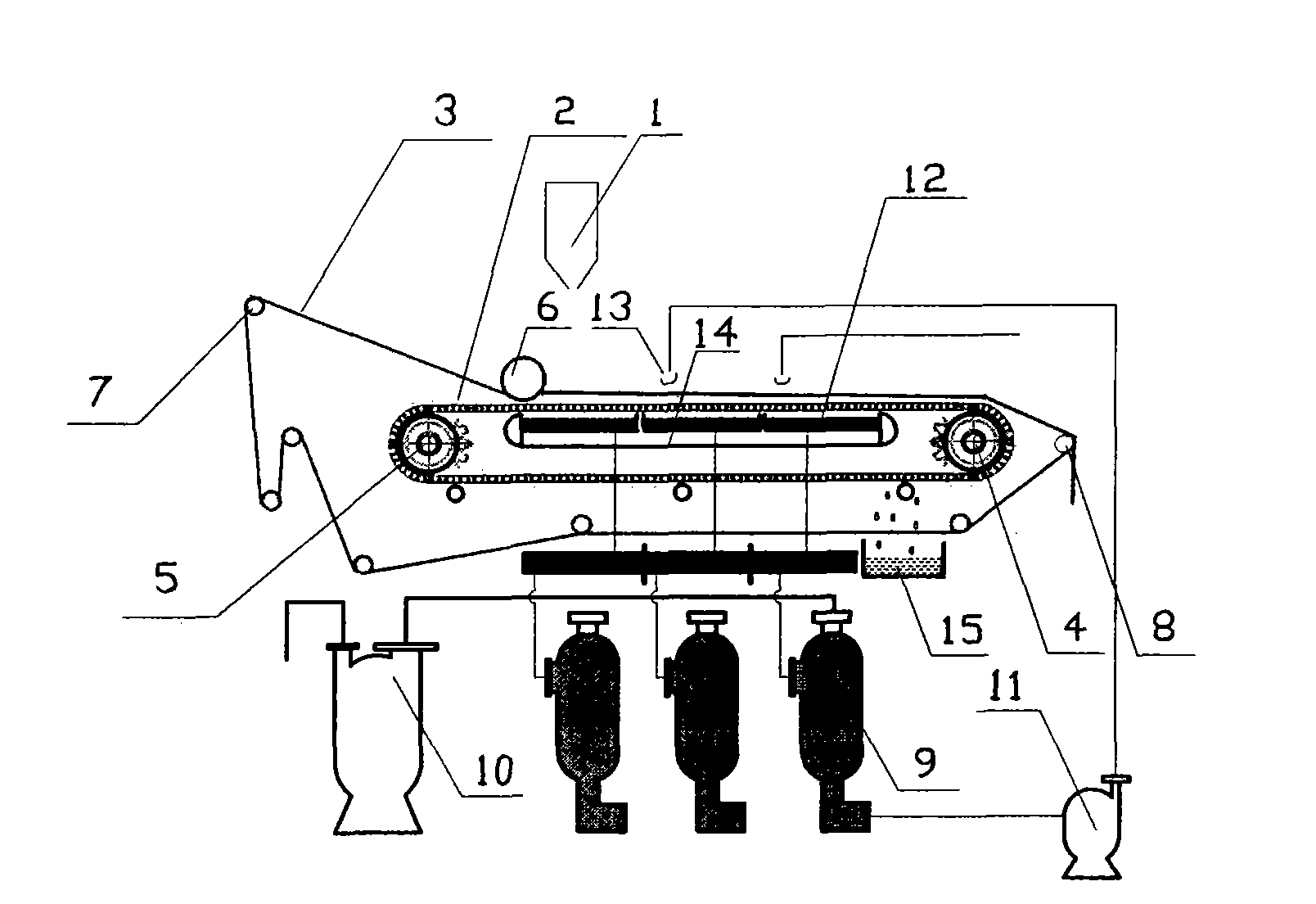

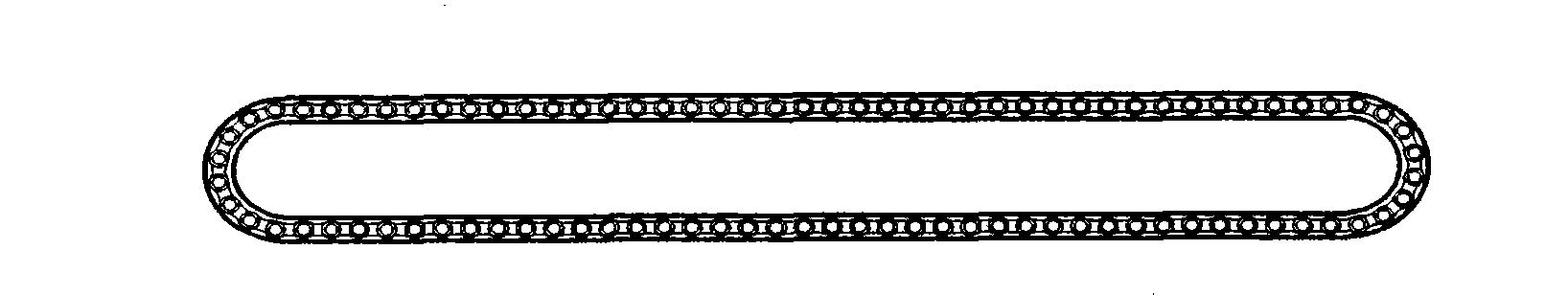

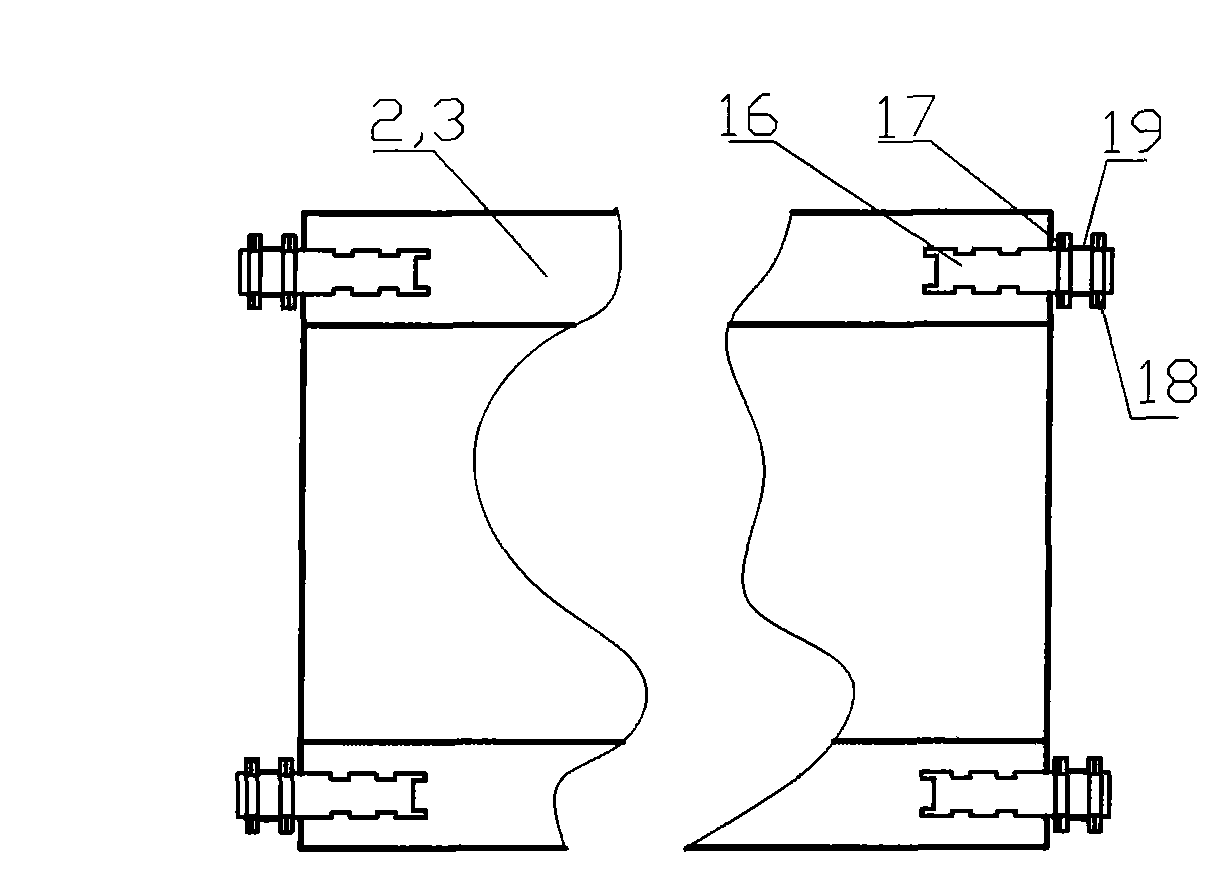

[0023] Such as figure 1 As shown, a double-belt non-correction rubber belt vacuum filter, which includes a rubber belt 2, a filter cloth belt 3 with a working surface attached to the rubber belt 2, and a rubber belt main / Driven wheels 4, 5, filter cloth belt master / driven wheels 6, 7, 8 matched with the filter cloth belt 3, vacuum box 12 fixedly placed under the rubber belt 2 and a gas-liquid separator equipped with a vacuum pump 10 9; the inlet of the gas-liquid separator 9 communicates with the vacuum box 12 through the pipeline; the ends of both sides of the rubber belt 2 or the filter cloth belt 3 are respectively provided with sprocket transmission mechanisms; the filter cloth belt master / slave Driven wheel 6,7,8 and rubber belt master / driven wheel 4,5 adopt the sprocket wheel that is engaged with described sprocket wheel transmission mechanism.

[0024] The present invention also has a water return pump 11 and a wetting device 13; the inlet of the water return pump 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com