Method for predicting the dynamic behaviour of an aircraft structure

A dynamic performance, aircraft technology, applied in the direction of measuring vibration, rigid supports of machines/engines, bearing components, etc., can solve the problem of not having any method to accurately predict vibration frequency and vibration amplitude, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

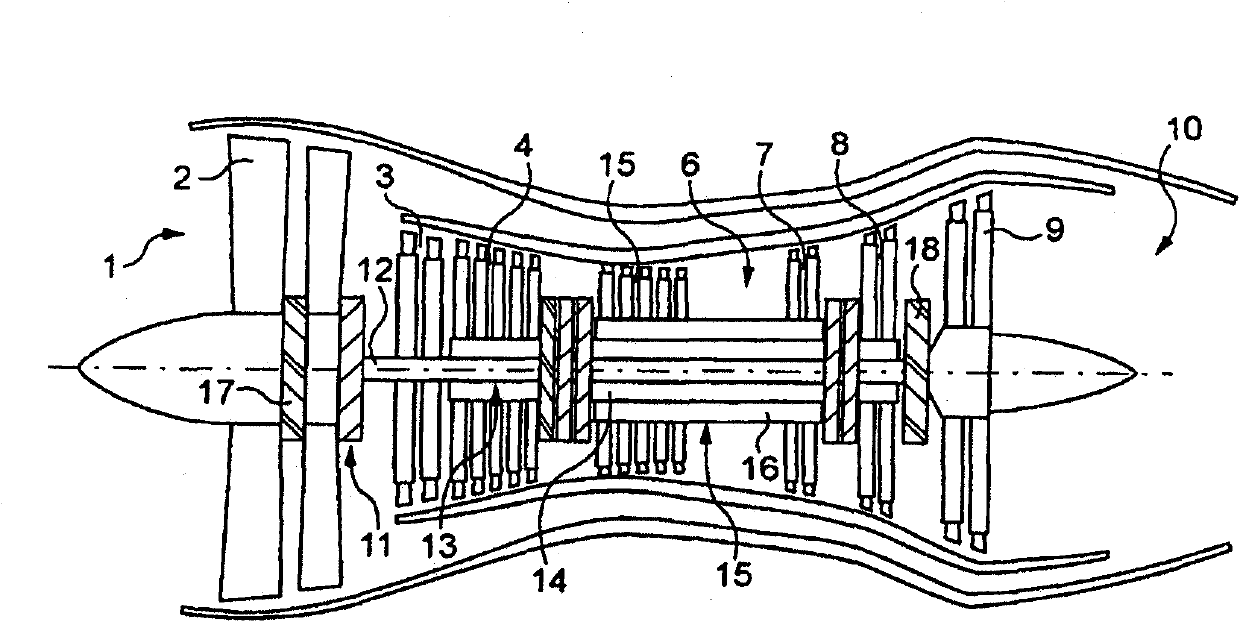

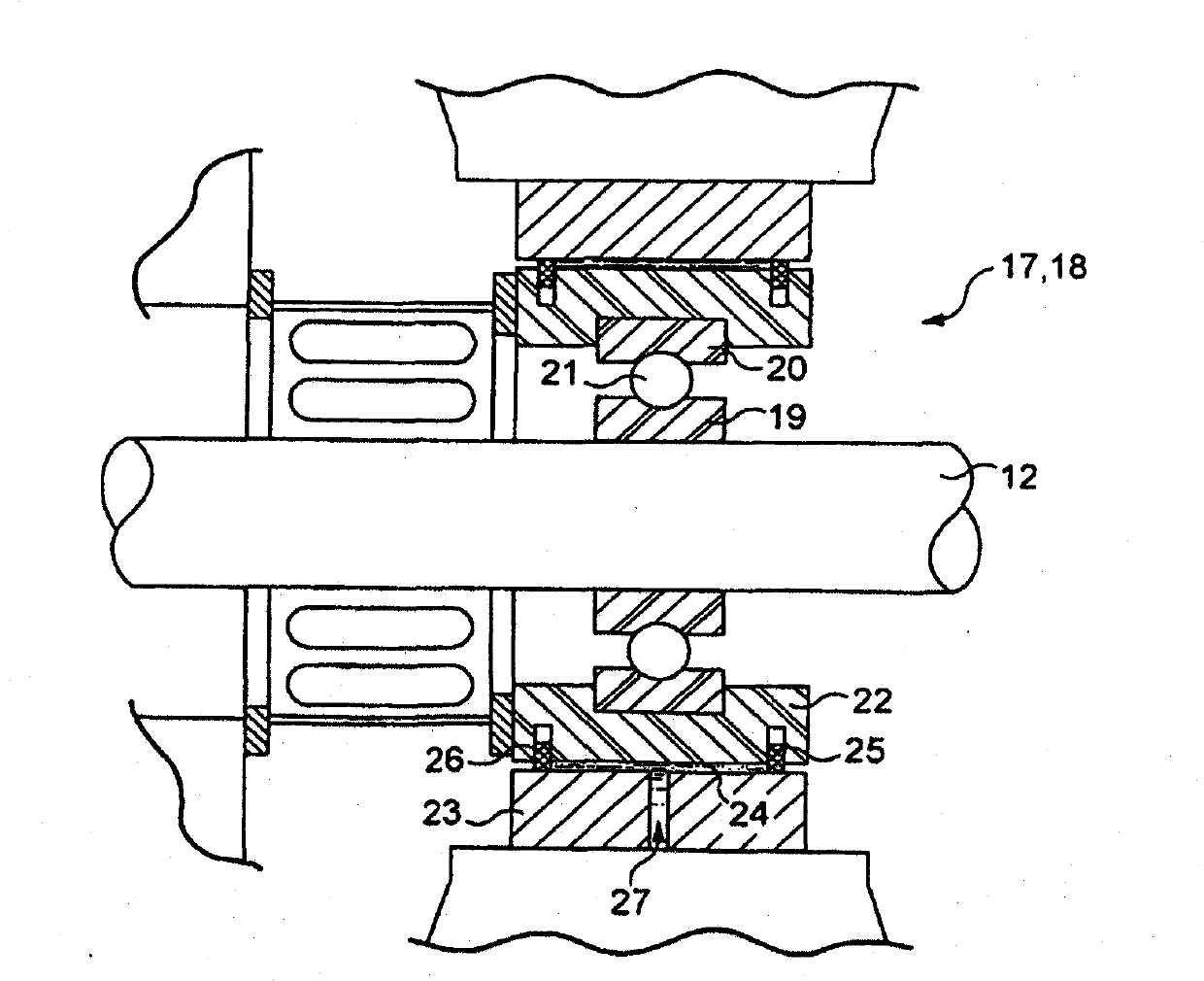

[0074] Certain airplanes or other known aircraft include engines with rotors, such as twin-body or triple-body turbojets. figure 1 A three-body turbojet engine is shown, generally comprising an air inlet 1, a compression zone comprising a large diameter blower 2 and several stages of compressors 3, 4, 5, a combustion chamber 6, comprising several stages of a turbine 7, 8, the gas expansion zone of 9, and the injection pipe 10. This turbojet engine consists of:

[0075] - a first rotor 11 called low-pressure rotor, which includes the blower 2, the low-pressure compressor 3, the low-pressure turbine 9 and the first shaft 12 supporting the above-mentioned elements;

[0076] - the second rotor 13, called the intermediate pressure rotor, comprising the intermediate pressure compressor 4, the intermediate pressure turbine 8, and the second shaft 14 supporting the aforementioned elements;

[0077] - A third rotor 15 , called the high-pressure rotor, comprising the high-pressure compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com