Control system for improving operation environment of substation equipment

A technology of equipment operation and control system, which is applied in the direction of temperature control using electric mode, cooling/ventilation of substation/switchgear, electrical program control, etc., which can solve problems such as increasing system energy consumption, aggravating the tension between power supply and demand, and poor energy efficiency , to improve cooling efficiency and avoid mixed and turbulent flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

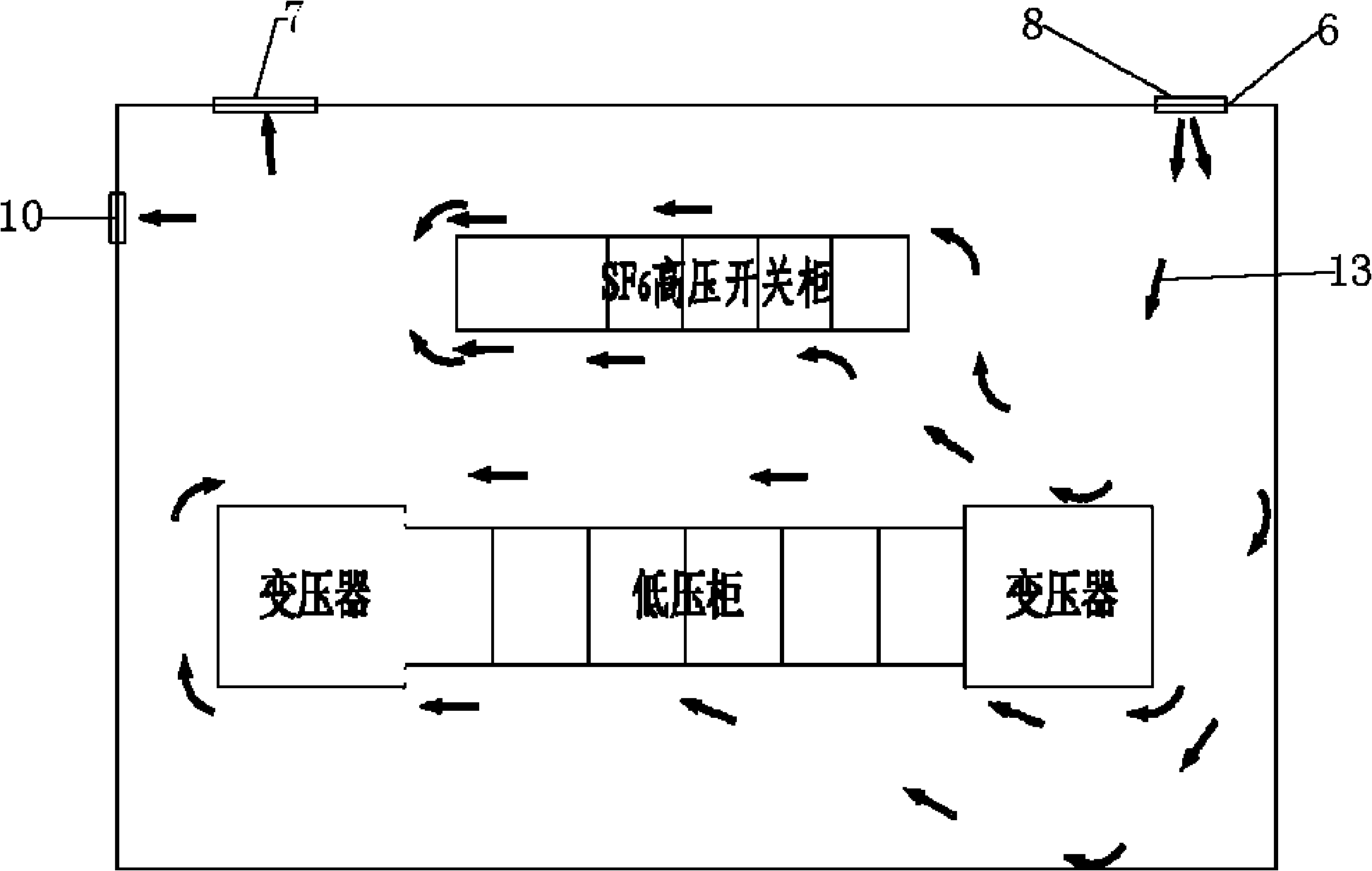

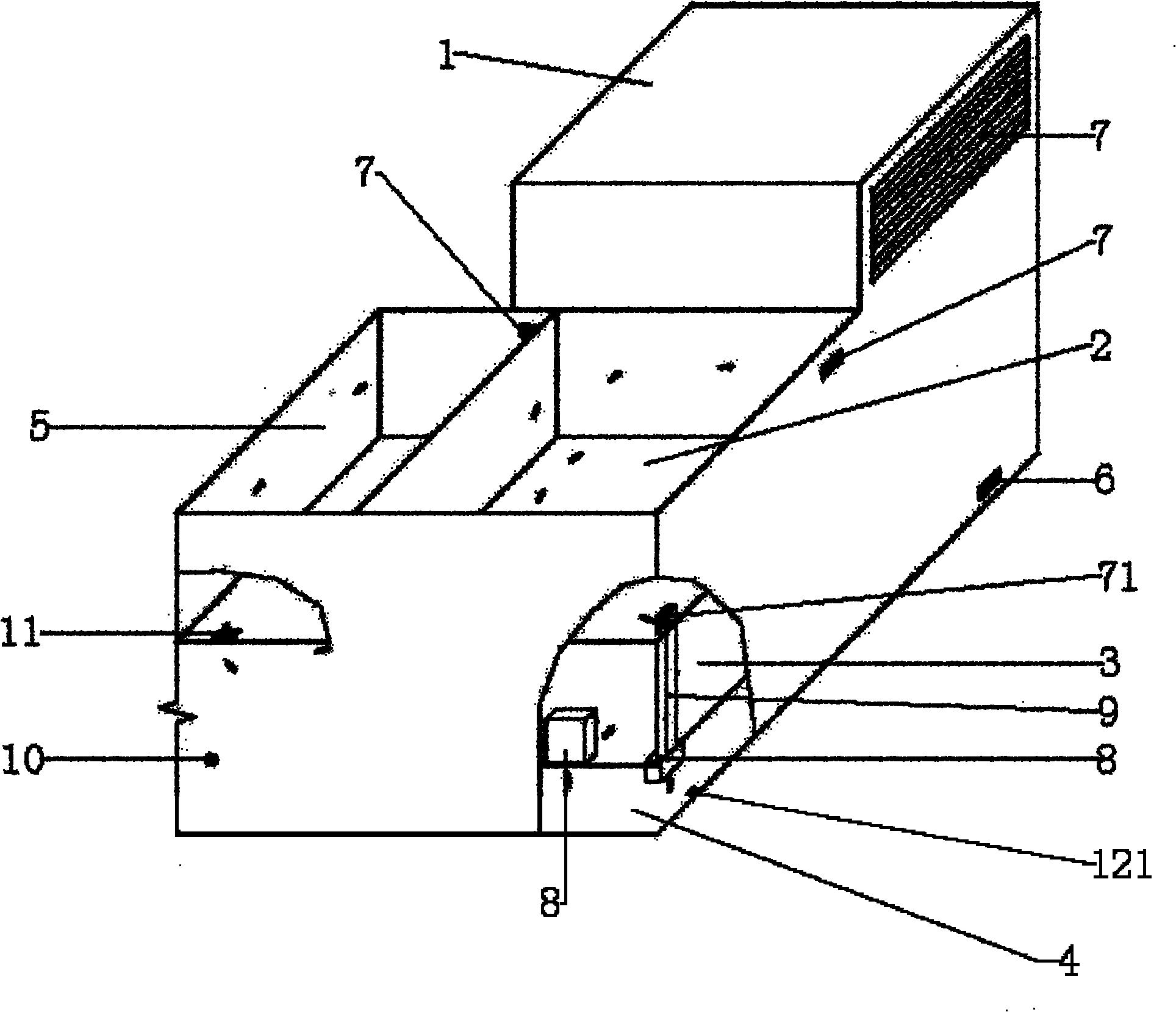

[0024] figure 1 , is a schematic diagram of the overall structure of the first embodiment of the control system for improving the operating environment of substation equipment disclosed by the present invention; figure 2 It is a schematic diagram of the horizontal flow of the bottom airflow in the enclosed space involved in the first embodiment of the control system for improving the operating environment of substation equipment in the present invention; Figure 8 The schematic diagram of the control information flow of the control system used to improve the operating environment of substation equipment in the present invention. Among them, it includes: air inlet 6; intelligent ventilation regulator 8, which is arranged at the above-mentioned air inlet 6, which can not only change the air volume, but also adjust the direction and angle of airflow. The intelligent ventilation regulator 8 can adopt the patent No. The Chinese utility model patent "intelligent temperature contro...

Embodiment 2

[0028] image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 A second embodiment of the present invention is disclosed.

[0029] The second embodiment is an embodiment after further improvement of the first embodiment, which includes: a main transformer room 1; a three-layer structure, adjacent to the side of the main transformer room 1, from top to bottom, two The control room 2 on the first floor, the capacitor room 5 on the second floor, the switch room 3 on the first floor, and the cable room 4 on the negative floor; compared with the first embodiment, the second embodiment also includes: a humidity sensor 123 for collecting humidity information inside the enclosed space And sent to the above-mentioned intelligent control unit 100; Water immersion sensor 121, for monitoring the water level information inside the closed space and sent to the above-mentioned intelligent control unit 100; Fire and explosion-proof device 11, arranged between the high-voltage capacitor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com